AGV intelligent scheduling method based on time window

An intelligent scheduling and time window technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as difficulty in simultaneous operation of AGV equipment, loop deadlock, and insufficient path capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

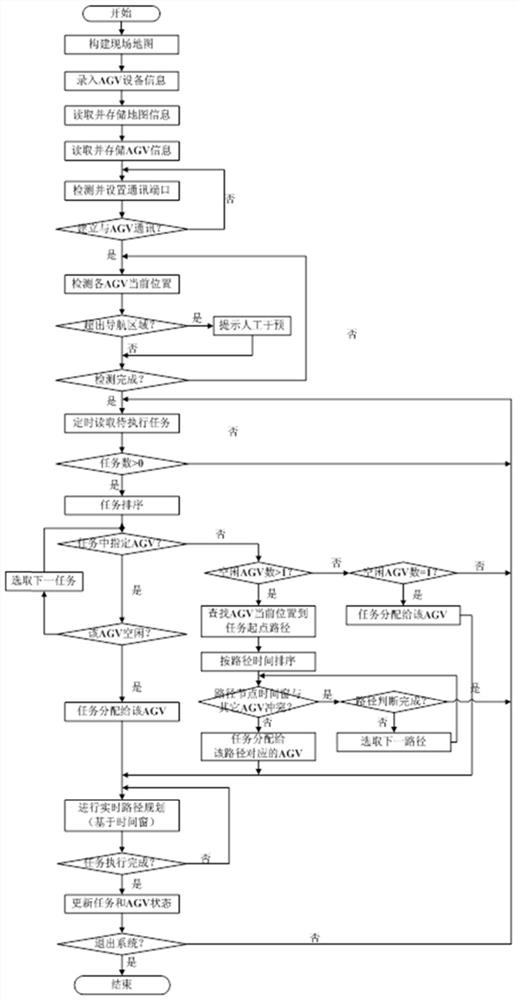

[0032] A time-window-based AGV intelligent scheduling method realizes automatic avoidance when multiple AGVs are running simultaneously in the same area by pre-judging the status of running path nodes, pre-occupying idle nodes based on time windows and automatically avoiding occupied nodes. Improve operational efficiency and operational safety, such as figure 1 As shown, the specific steps are:

[0033] (1) According to the characteristics of the site environment and the requirements of dispatching tasks, establish a laser navigation coordinate system, construct a site map, and plan to construct the operating path nodes of the automatic guided transport vehicle AGV, and calculate the coordinates and types of each operating path node in the laser navigation coordinate system , positioning mode and path direction are determined, and the site map file is generated according to the above-mentioned site map information; a matrix code is set at the position where visual navigation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com