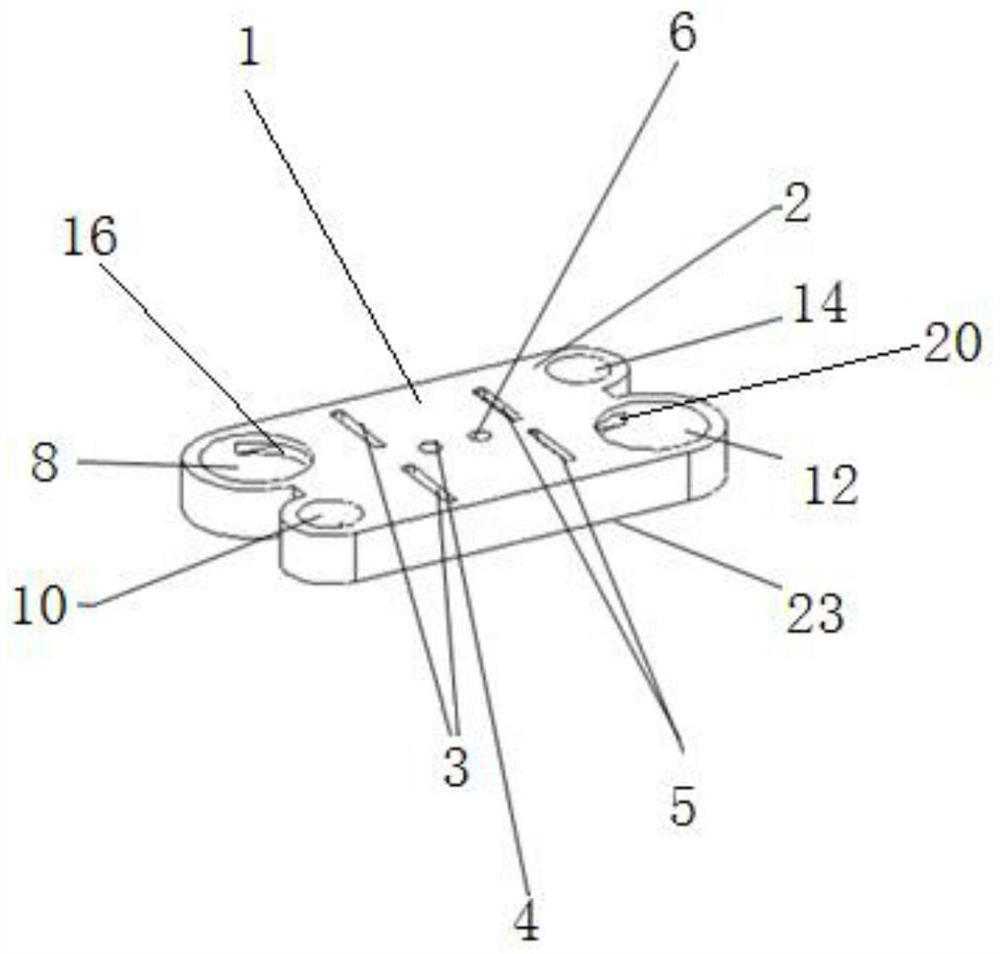

Manifold of solid oxide fuel cell stack and solid oxide fuel cell comprising same

A fuel cell stack and solid oxide technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve the problems of small integration and low space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

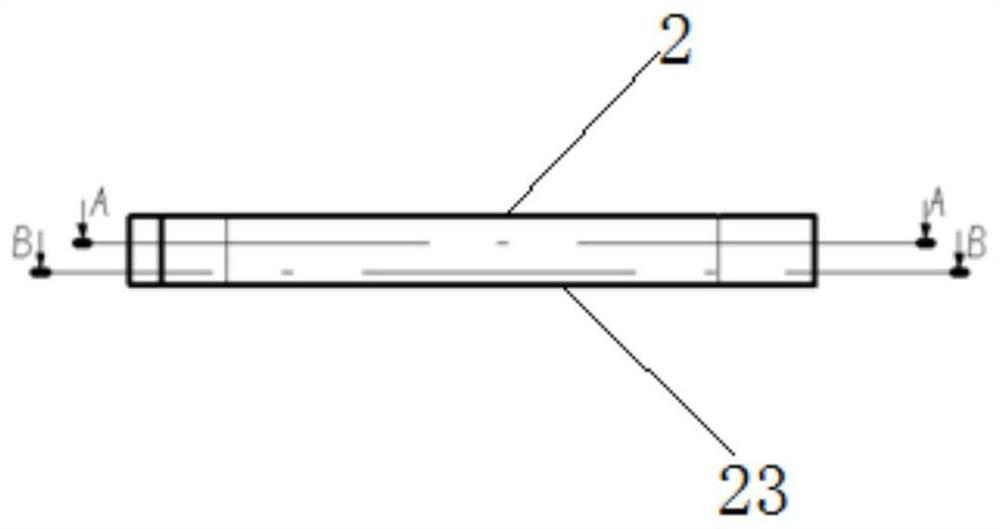

[0069] Using the vertical stacking of 5 electric stacks in this application, compared with the tiled arrangement, saves the space of the projected area of 4 electric stacks, and the electric stacks are used for power generation experiments, 32Nm 3 / h Air enters, the stack inlet temperature is 650°C-700°C, the air enters the manifold air inlet, manifold air inlet, first internal channel and manifold air outlet sequentially through the air delivery connecting pipe located on the side of the stack The cathode of the stack, the surface of the cathode adsorbs oxygen, and the catalytic effect on the surface of the cathode makes the O 2 Gain electrons and become O 2- , O 2- Diffusion to the anode surface; 20L / min, stack inlet temperature 650°C-700°C, methane gas enters the manifold gas inlet hole, manifold gas inlet, second internal channel and The manifold gas outlet enters the anode of the stack, and O 2- A reaction occurs, and the lost electrons return to the cathode through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com