Woven film, woven bag and weaving method

A technology of woven bags and degradable materials, which is applied in tissue regeneration, non-woven fabrics, textiles and papermaking, etc., can solve the problems of elastic modulus difference, narrow treatment range, large trauma, etc., and achieve good biocompatibility and safety , good biocompatibility, the effect of avoiding stress disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The woven film is divided into three layers. The degradable material of the middle layer can choose one of PLGA or PLLA or a combination of both. Its weight ratio is 40%-70%, and the degradation time is 3-6 months. The degradable material can choose one of PLGA or PLLA or a combination of both, and its weight ratio is 40%-60%, and the degradation time is 6-12 months. The non-degradable materials of the core layer, the middle layer, and the outer layer can be Choose PET or PBT or a combination thereof.

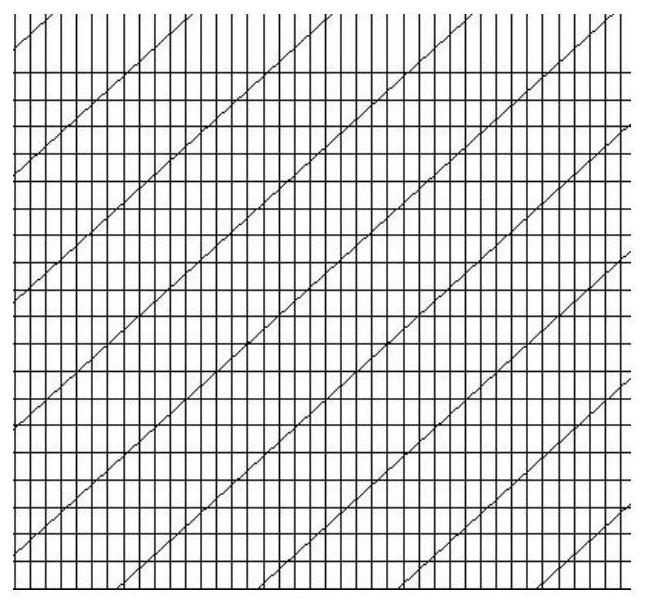

[0034] attached figure 1 It is a schematic diagram of the braided membrane of Example 1.

[0035] Experimental group:

[0036] Control group: PET woven film;

[0037] Experimental group 1: core layer-PET woven film; middle layer-40% PLLA+60% PET blended woven film; outer layer 50% PLGA+50% PET blended woven film;

[0038] Experimental group 2: core layer-PET woven film; middle layer-60% PLGA+40% PET blended woven film; outer layer 50% PLLA+50% PET blended woven film;...

Embodiment 2

[0046] A woven film is characterized in that it has three layers, the core layer is made of PET material, the middle layer is made of mixed weaving of 60% PLLA and 40% PET material by weight, and the outer layer is made of 50% PLGA and 50% by weight Made of PET material blend weave.

[0047] The effect data is consistent with the data of experimental group 2 in Example 1.

Embodiment 3

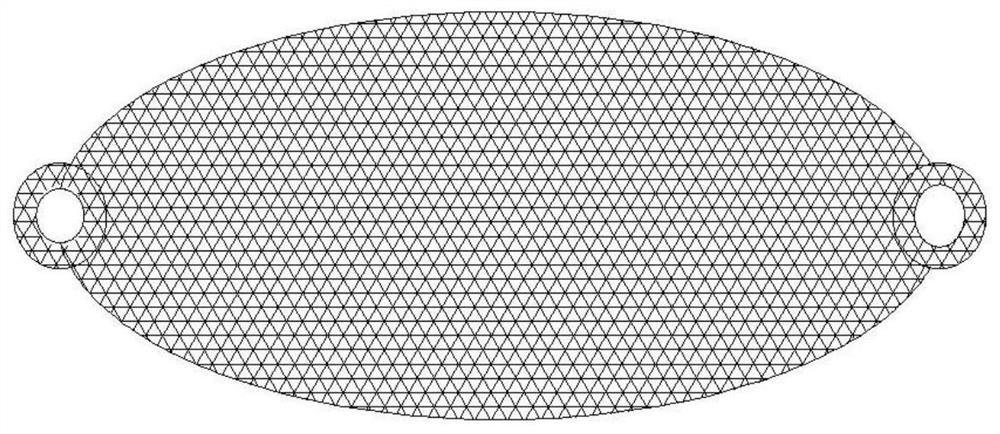

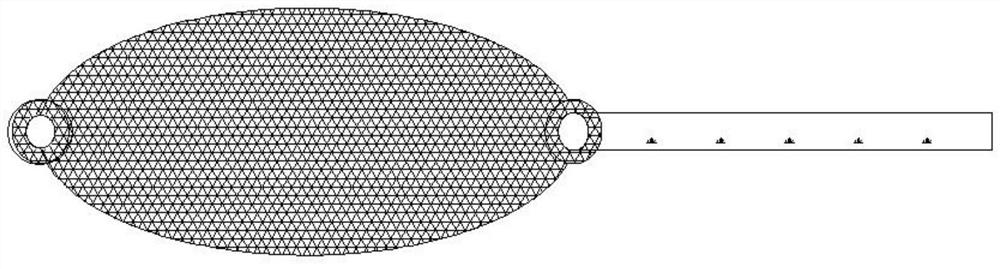

[0049] The woven bag uses the woven film of Example 2, and the woven film is made into a cylindrical woven film with two ends opened by 3D electrospinning technology. It contains two ports: the first port and the second port. The first port seals and fixes the opening at one end of the braided membrane, and the second port seals and fixes the opening at the other end of the braided membrane while having a loosening effect.

[0050] The 3D classic spinning technology can realize the membrane into a three-dimensional cylindrical structure. The two ends of the cylinder are tightened and fixed and sealed by two ports to ensure that there will be no leakage when filling the bone cement. The second port In addition to the sealing function, it is also a channel for the woven bag to communicate with the outside, and its loosening effect can make it easier to break away from the device for conveying the woven bag.

[0051] Certainly, the woven bag of embodiment 3 has preferred shape an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com