Absorbent paper macromolecule positioning and spreading process

A polymer and water-absorbing paper technology, applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve problems such as high cost and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

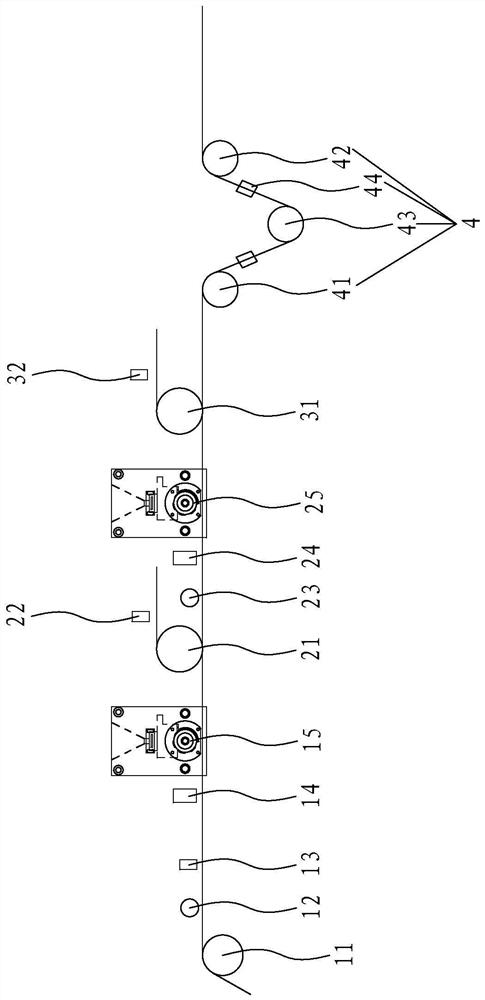

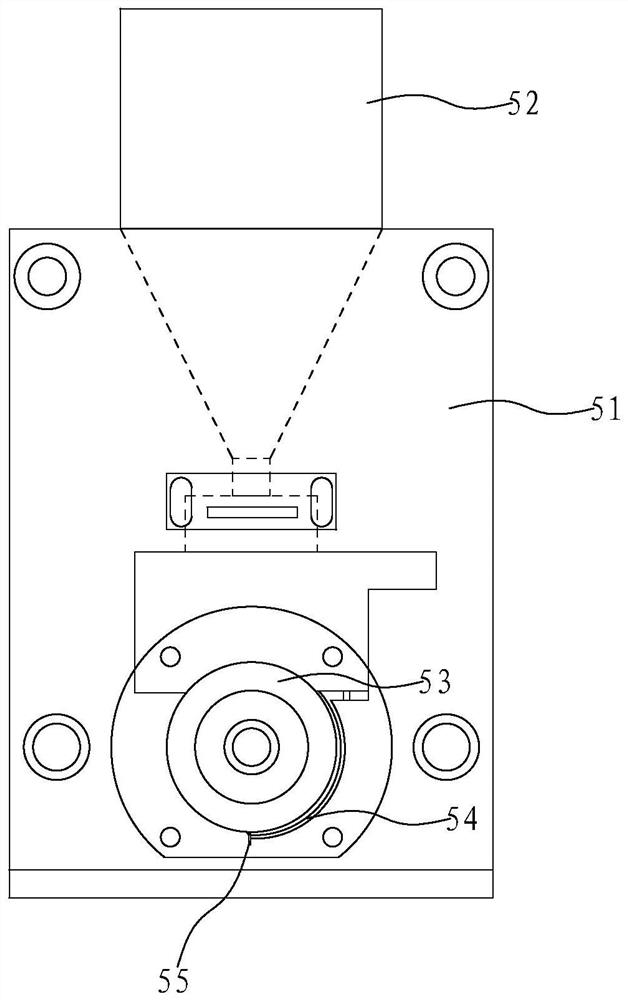

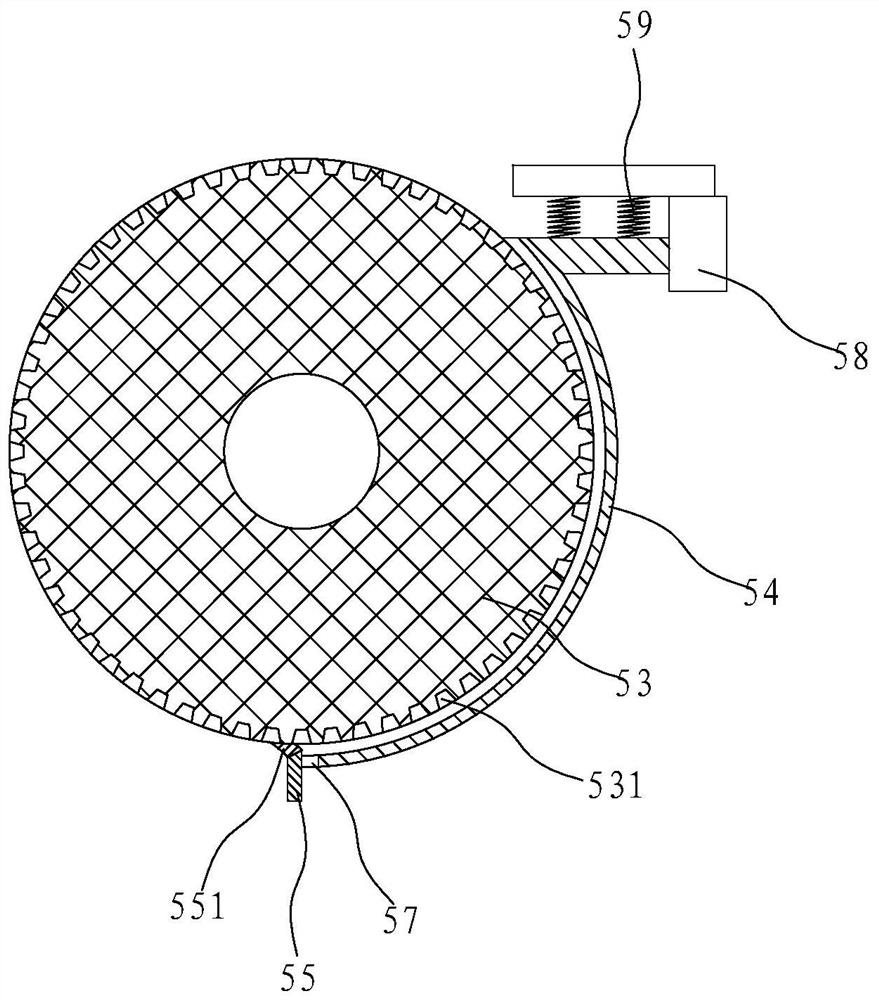

[0038] refer to Figure 1 to Figure 4 , the present embodiment provides a kind of water-absorbing paper macromolecule positioning spreading device, comprises frame and is arranged on the lower layer material input device 11 on the frame according to the assembly line, the first color code processing device 12, the first glue spraying device 13, the first Color mark identification device 14, first polymer positioning spraying device 15, fluffy non-woven fabric input device 21, second glue spraying device 22, second color mark processing device 23, second color mark recognition device 24, second polymer Position the spraying device 25 , the lower layer material input device 31 , the third glue spraying device 32 , and the vibrating device 4 .

[0039] The lower material input device, the fluffy non-woven fabric input device, the lower material input d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com