NiAl alloy complicated thin-wall hollow component shaping method

An alloy and complex technology, applied in the field of forming NiAl alloy complex thin-walled hollow components, can solve the problems of material performance difference, difficult deformation and high production cost in the area near the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

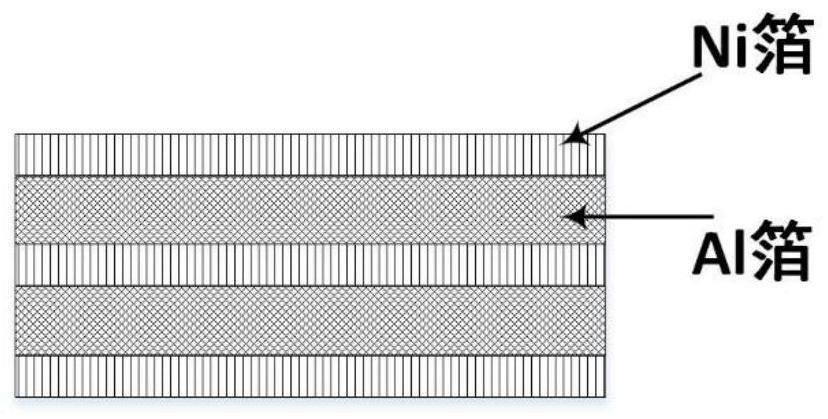

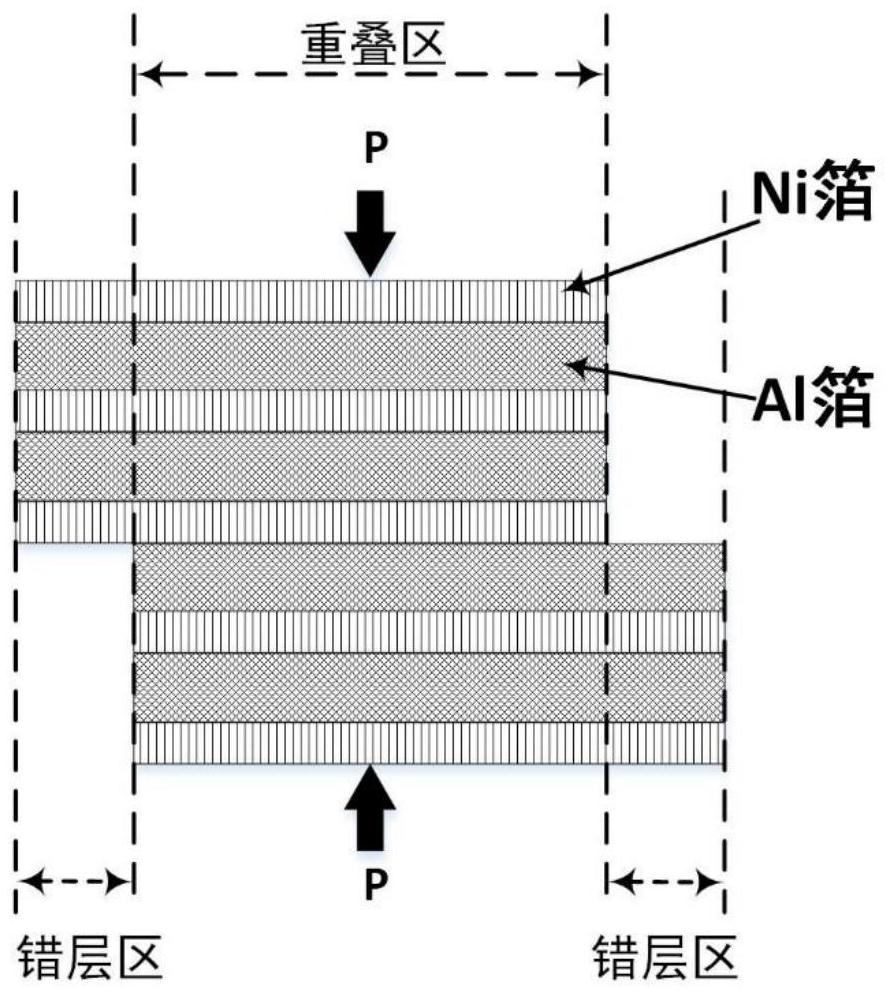

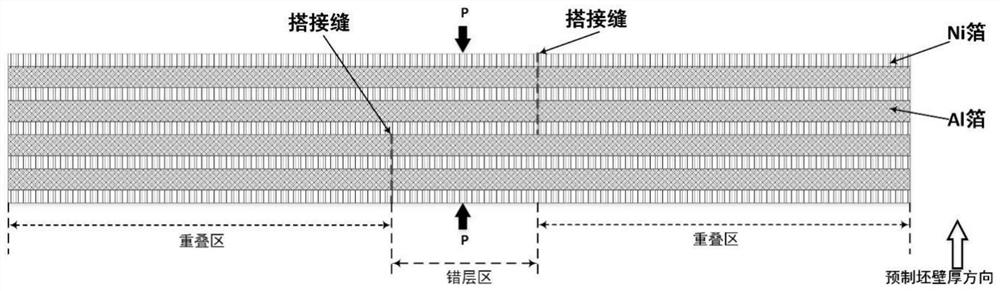

Method used

Image

Examples

Embodiment 1

[0076] A preparation and forming method of a NiAl alloy complex thin-walled hollow component, the structure of the complex thin-walled hollow component is as follows Figure 4 shown. Its main characteristics are as follows: (i) the shape is complex, the section at one end is circular, the section at the other end is rectangular, and there is a linear transition in the length direction, that is, the shape of the section changes greatly; (ii) the perimeter of the section varies greatly, and the perimeter of the rectangular section is 2.0 times the circumference of the circular section; (iii) the wall thickness is small, and the wall thickness ranges from 1.0 to 2.5mm, that is, the rigidity is weak and the dimensional accuracy is difficult to control; (iv) the wall thickness uniformity is high, and the wall thickness tolerance is ±0.2mm; (v) High temperature performance and high safety and reliability requirements. The above characteristics show that it is extremely difficult to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strain rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com