A powder loading method for beryllium material forming blanks for cetr reactor

A technology for reactors and forming blanks, which is applied in the field of powder loading of beryllium material forming blanks for CETR reactors. It can solve the problems affecting the performance of forming blanks and material stability, low production efficiency, and a large amount of raw material powder, etc., to achieve satisfactory performance and material stability. High performance requirements, high powder loading efficiency, and pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

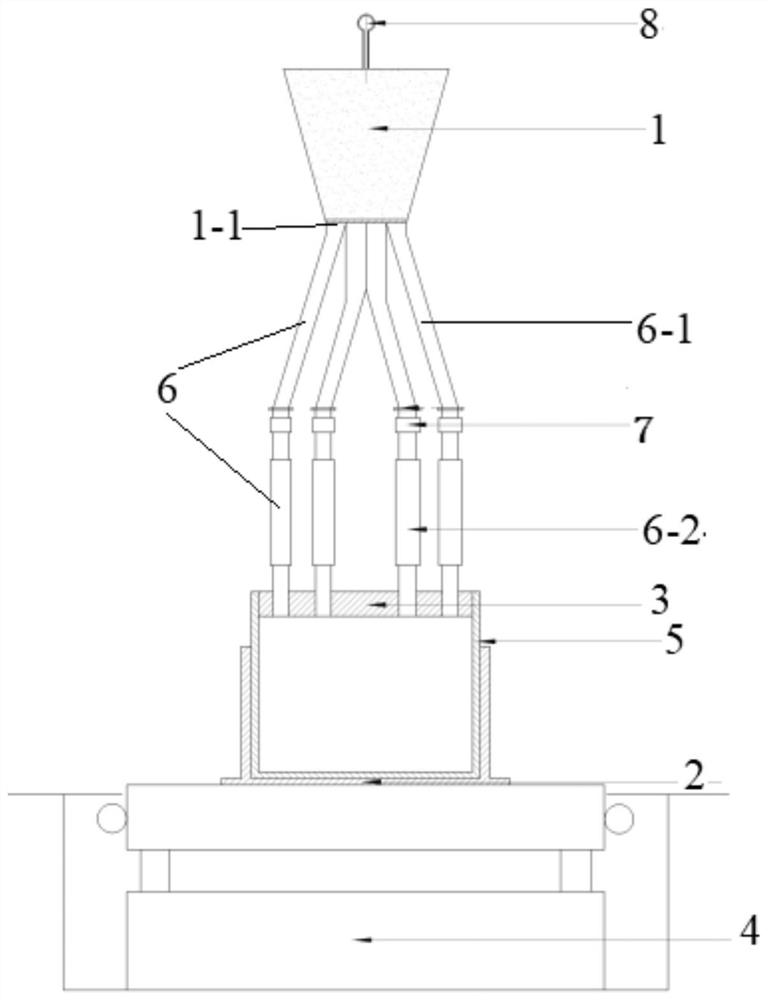

[0048] Step 1. Calculate the required beryllium powder filling amount of 50kg according to the size of the envelope 5 and the density of the beryllium powder;

[0049] Step 2, prepare the material according to the required beryllium powder filling amount of 50kg and pack it into the feeder 1 of the airtight blanking device and seal it;

[0050] Step 3, start the first vibrating motor, drive the feeder 1 to vibrate and feed the beryllium powder into the envelope 5 sealed with the feeder 1;

[0051] Step 4, according to the amount of beryllium powder in the feeder 1, start the second vibration motor, adjust the vibration frequency of the vibration platform 4, and vibrate the beryllium powder in the package 5;

[0052] The adjustment of the vibration frequency of the vibration platform 3 is as follows:

[0053] Observing through the observation port on the feeder 1, when the beryllium powder filling in the feeder 1 is 90%, adjust the vibration frequency of the vibration platform...

Embodiment 2

[0055] Step 1. Calculate the required beryllium powder filling amount of 70kg according to the size of the envelope 5 and the density of the beryllium powder;

[0056] Step 2, prepare the material according to the required beryllium powder filling amount of 70kg and pack it into the feeder 1 of the airtight blanking device and seal it;

[0057] Step 3, start the first vibrating motor, drive the feeder 1 to vibrate and feed the beryllium powder into the envelope 5 sealed with the feeder 1;

[0058] Step 4, according to the amount of beryllium powder in the feeder 1, start the second vibration motor, adjust the vibration frequency of the vibration platform 4, and vibrate the beryllium powder in the package 5;

[0059] The adjustment of the vibration frequency of the vibration platform 3 is as follows:

[0060] Through the observation port on the feeder 1, when the beryllium powder filling in the feeder 1 is 95%, the vibration frequency of the vibration platform 4 is adjusted to...

Embodiment 3

[0062] Step 1, according to the size of the envelope 5 and the density of the beryllium powder, calculate the required filling amount of beryllium powder 300kg;

[0063] Step 2, prepare the material according to the required beryllium powder filling amount of 300kg and load it into the feeder 1 of the airtight blanking device and seal it;

[0064] Step 3, start the first vibrating motor, drive the feeder 1 to vibrate and feed the beryllium powder into the envelope 5 sealed with the feeder 1;

[0065] Step 4, according to the amount of beryllium powder in the feeder 1, start the second vibration motor, adjust the vibration frequency of the vibration platform 4, and vibrate the beryllium powder in the package 5;

[0066] The adjustment of the vibration frequency of the vibration platform 3 is as follows:

[0067] Observing through the observation port on the feeder 1, when the beryllium powder filling in the feeder 1 is 90%, adjust the vibration frequency of the vibration platf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com