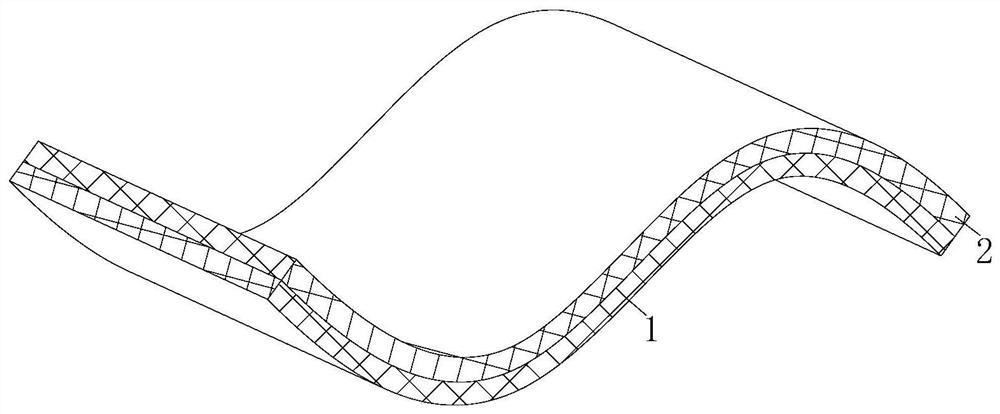

Waterproof, breathable and washing-resistant seamless woven fabric

A waterproof, breathable and fabric technology, applied in the field of seamless woven fabrics, can solve the problems of uneven surface of the expanded yarn, uneven expansion of the slurry, affecting the waterproof effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

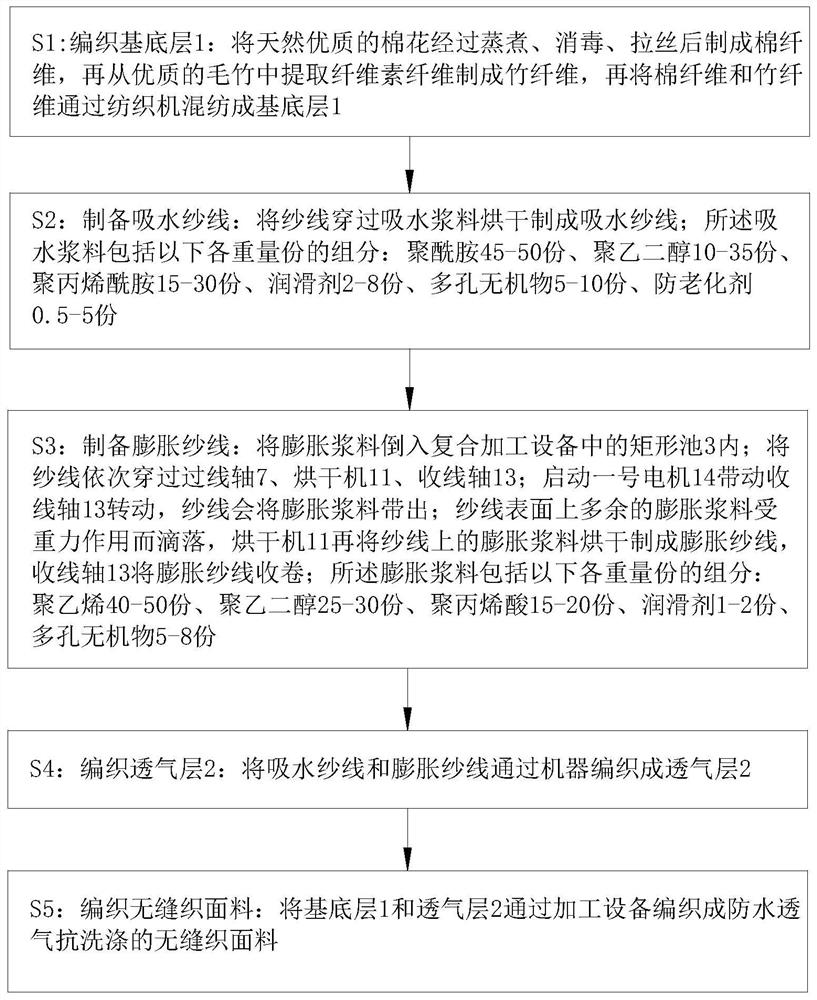

Method used

Image

Examples

Embodiment approach

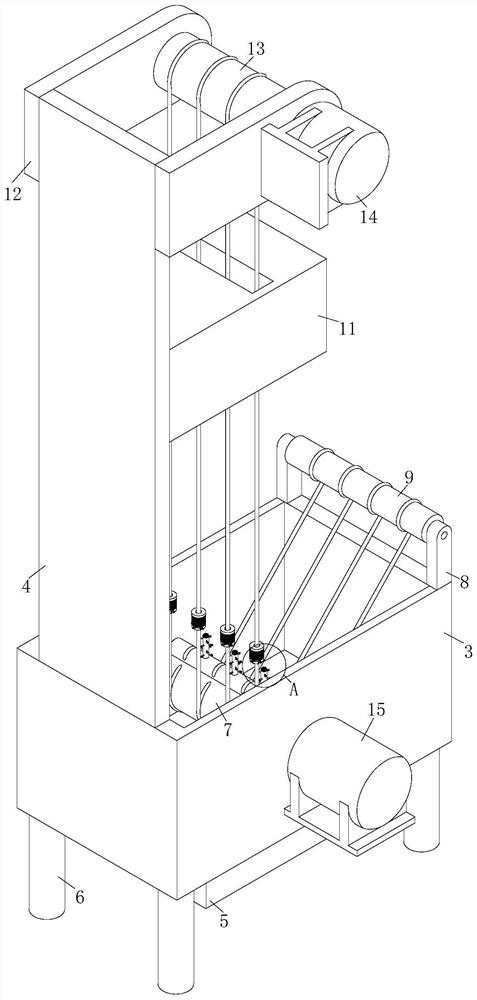

[0038] As an embodiment of the present invention, a stirring rod 721 is fixedly connected to the No. 1 protrusion 72; a group of stirring rods 722 is fixedly connected to the stirring rod 721; there are at least three stirring rods 722, and the stirring rods 722 Two discs 723 are fixedly connected to the ends of the two discs 723; the two discs 723 are arranged in a cross; during use, after the excess expansion slurry on the surface of the yarn stays in the air for a period of time, the temperature of the expansion slurry At the same time, the expansion slurry drops into the rectangular pool 3 under the action of gravity, so that the temperature of the expansion slurry in the rectangular pool 3 is different from other places, thereby affecting the viscosity of the expansion slurry at this place; therefore, this The invention worker starts No. 2 motor 15, and drives the spool 7 to rotate by No. 2 motor 15. Because the spool 7 is provided with a No. 1 protrusion 72, and the No. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com