A kind of synthetic method of 2-(1-cyclohexenyl) ethylamine

A technology of cyclohexenyl and synthetic method, which is applied in the field of compound 2-ethylamine synthesis, can solve the problems of high yield, high cost, difficult industrial implementation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

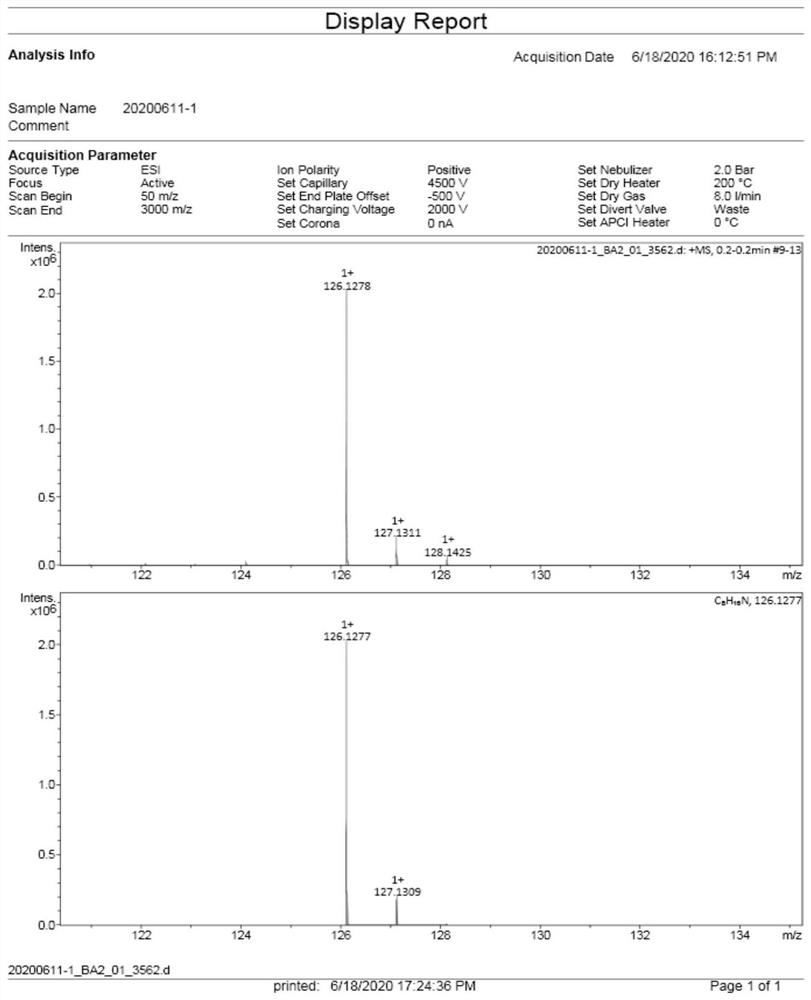

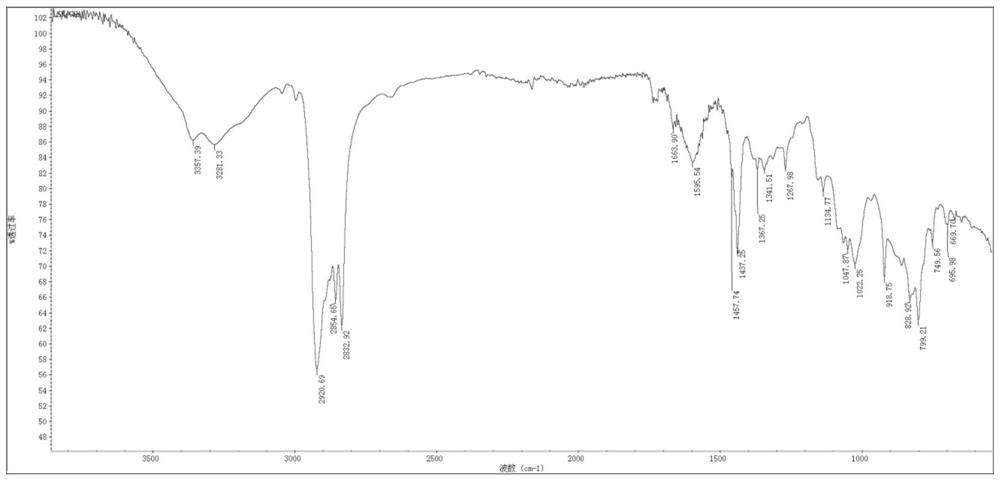

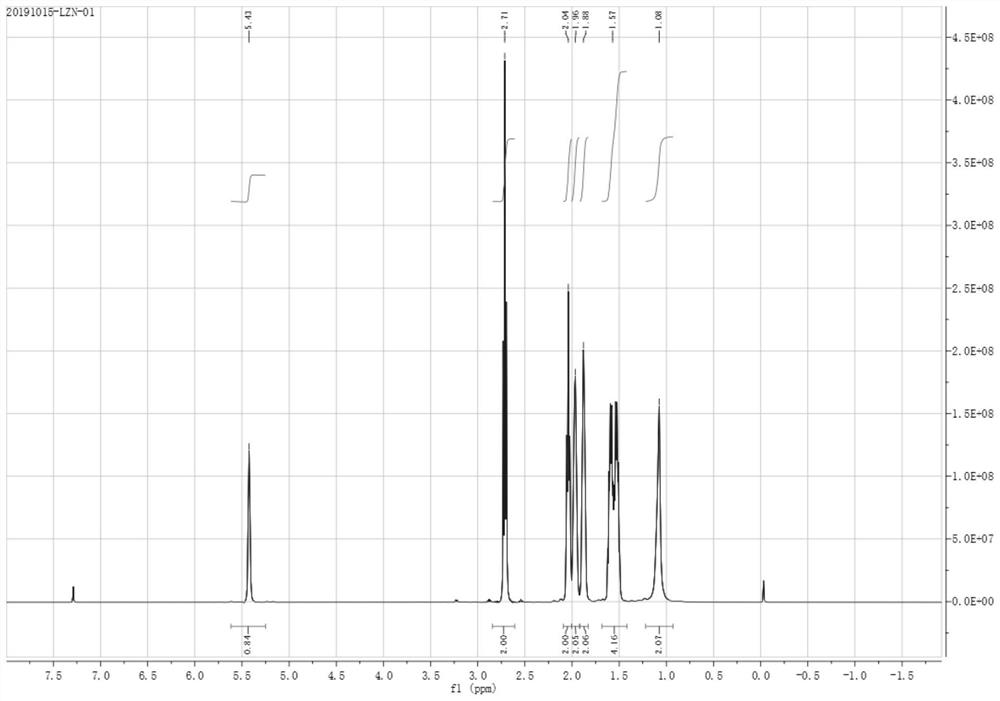

Image

Examples

Embodiment 1

[0042] Example 1: The compound cyclohexanone (II, 9.8g, 0.1mol) was mixed with 200mL tetrahydrofuran, and after cooling to 0°C in an ice bath, a tetrahydrofuran solution of vinylmagnesium chloride (1.6M, 100mL) was added, and stirred at room temperature for 10 hours After quenching with a saturated ammonium chloride solution, the organic phase was separated, the aqueous phase was extracted twice with ethyl acetate, and the organic phases were combined and concentrated to obtain 12.4 g of crude product of 1-vinylcyclohexanol (III).

Embodiment 2

[0043] Example 2: The compound cyclohexanone (II, 9.8g, 0.1mol) was mixed with 200mL tetrahydrofuran, and after cooling to 0°C in an ice bath, a tetrahydrofuran solution (1M, 150mL) of vinylmagnesium bromide was added, and stirred at room temperature for 6 Quenched with ammonium chloride saturated solution after 1 hour, separated the organic phase, extracted the aqueous phase twice with ethyl acetate, combined the organic phases, and concentrated it to obtain 12.6 g of the crude product of 1-vinylcyclohexanol (III) .

[0044] Two, the preparation of (2-chloroethylmethylene) cyclohexane (IV)

[0045] Example 1: 12.6g of 1-vinylcyclohexanol (III, 12.6g, 0.1mol) prepared in the previous step was mixed with 150mL of tetrahydrofuran, and after ice bathing to 0°C, pyridine (14.22g, 0.18mol) and Thionyl chloride (18.88g, 0.16mol), after stirring the reaction for 45min, 3 The saturated solution was quenched, the organic phase was separated, the aqueous phase was extracted twice with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap