High-alkalinity sintered ore material, sintering method thereof and sintered ore

A high alkalinity, sintered ore technology, applied in the field of sintered ore sintering, can solve the problems of high ore return rate and low utilization coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 5

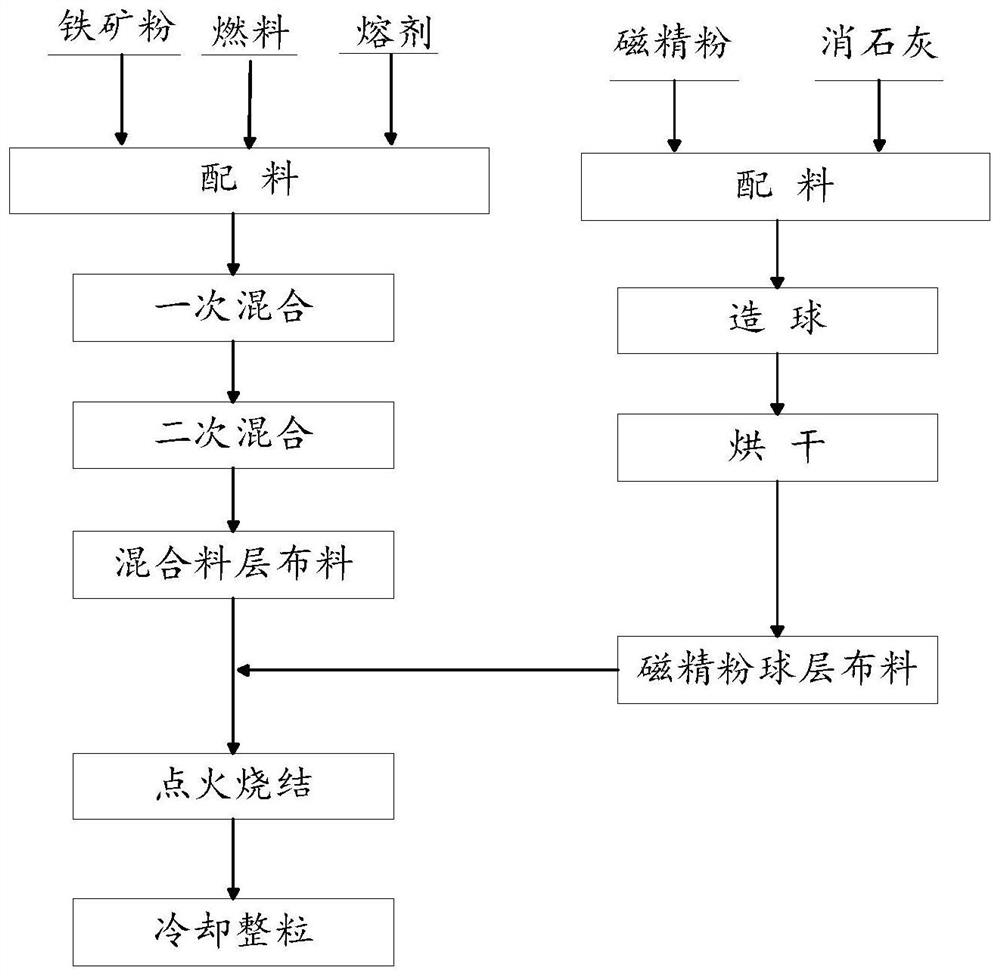

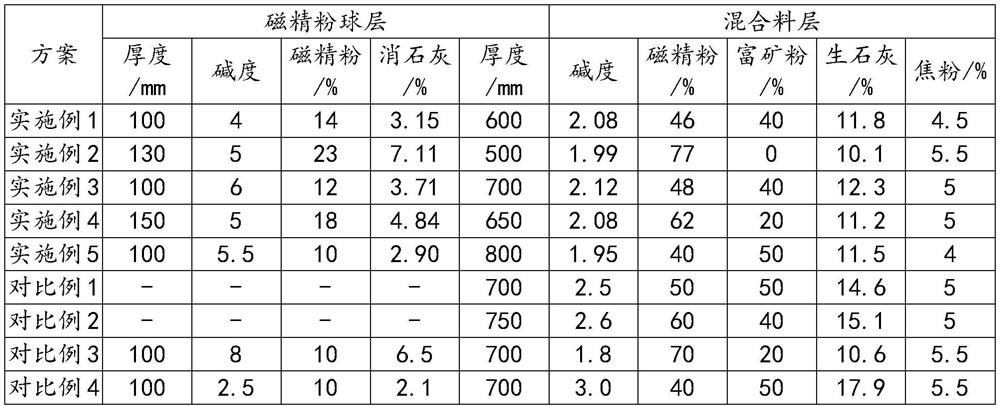

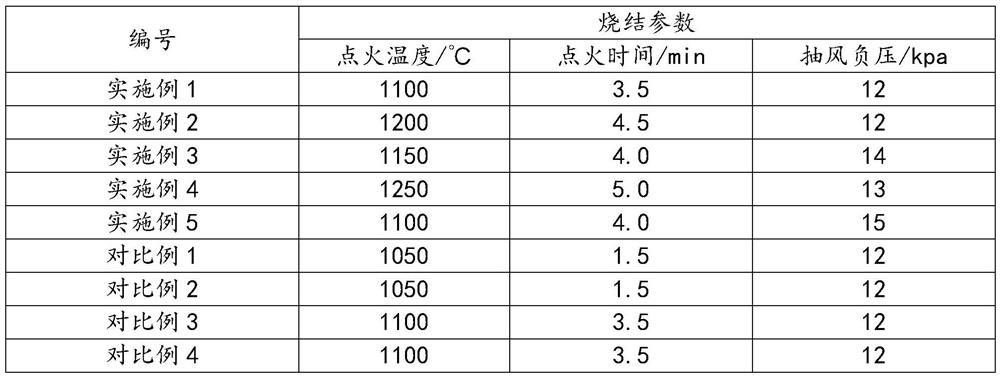

[0057] Embodiment 1 to embodiment 5 provide a kind of sintering method of high alkalinity sintered ore material, wherein all iron-containing raw materials mentioned refer to the magnetic fine powder in the magnetic fine powder ball, the magnetic fine powder and the rich ore powder in the mixture , the sum of the masses of the three. The method includes the following steps:

[0058] (1) Prepare a material with an alkalinity of 4-6 with 10-30% of the mass percentage of all iron-containing raw materials and 2-5% of slaked lime, and prepare it into 8-12mm by pelletizing disc High alkalinity magnetic fine powder balls, dry the magnetic fine powder balls. The sintering mixture is prepared by preparing magnetic fine powder, 0-50% rich ore powder, 10-15% quicklime, and 3-5% coke powder respectively accounting for 40-80% of the mass percentage of all iron-containing raw materials. The basicity is 1.9-2.3, and the sintered mixture is mixed once and twice.

[0059] (2) Use sintered or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com