Heat removal device for etching treatment of silicon material and working method of heat removal device

A technology of etching treatment and heating device, which is applied in the field of single crystal silicon preparation, and can solve problems such as production accidents, corrosion and damage of heat exchangers, corrosion of condensers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

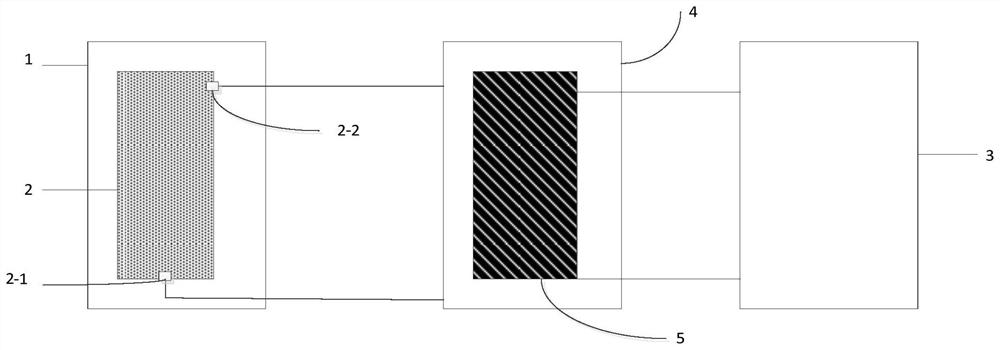

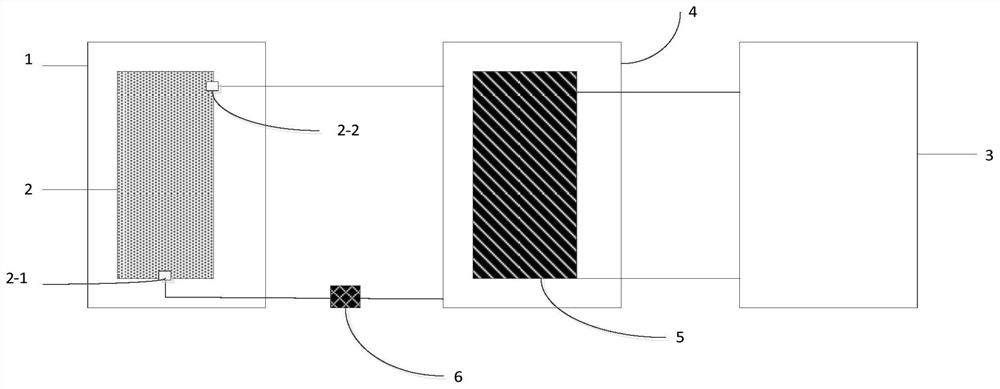

[0074] A heat removal device for etching silicon-based materials, comprising:

[0075] Reagent tank;

[0076] The first heat exchanger installed in the reagent tank, the medium circulating in the first heat exchanger is water, and the water inlet and outlet of the first heat exchanger are connected to the intermediate heat exchange tank to form a circulation Circuit; the capacity of the reagent tank is about 80L.

[0077] A pump is arranged between the water inlet of the first heat exchanger and the intermediate heat exchange tank to drive the flow of the medium in the first heat exchanger. The first heat exchanger is a spiral serpentine tube heat exchanger made of PFA. The inner diameter of the spiral serpentine tube is 12.7mm, the thickness is 1.5mm, and the length is 10m. The heat transfer area at this time is 3.19m 2 .

[0078] A second heat exchanger is arranged in the intermediate heat exchange tank, and the intermediate heat exchange tank is filled with water;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com