Screw type vacuum pump with high vacuum degree

A high vacuum, vacuum pump technology, used in rotary piston pumps, pumps, rotary piston/swing piston pump components, etc., can solve the problem of not ensuring the heat dissipation function of the pump body, increasing power, space and maintenance, loss of vacuum effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

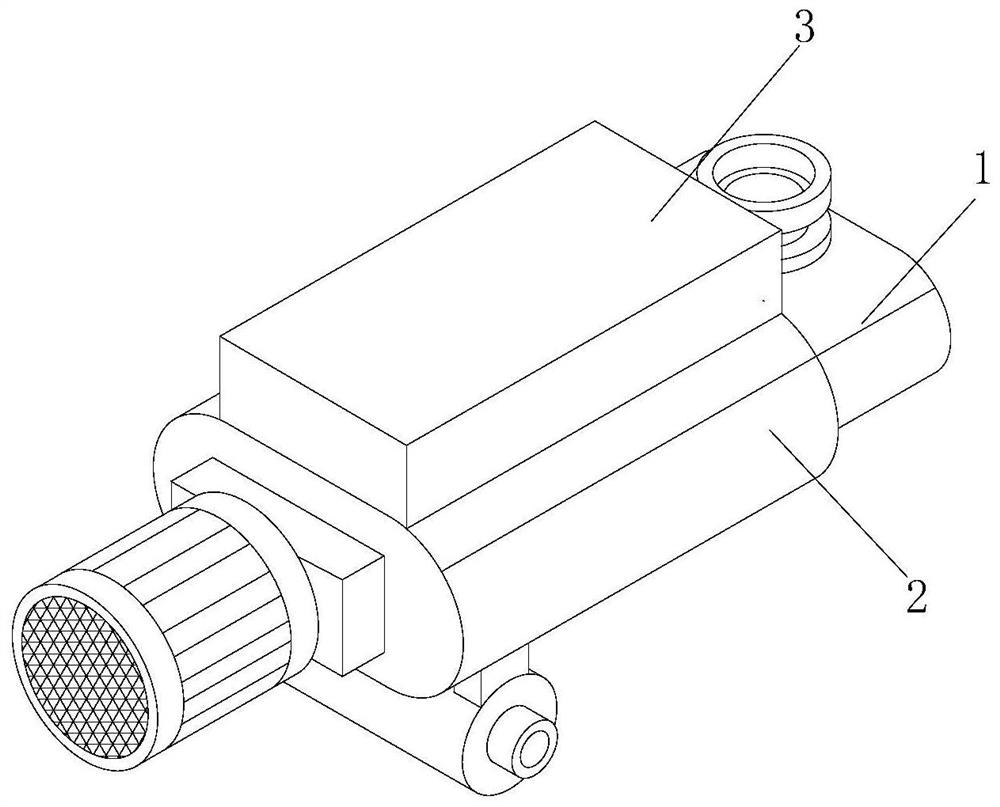

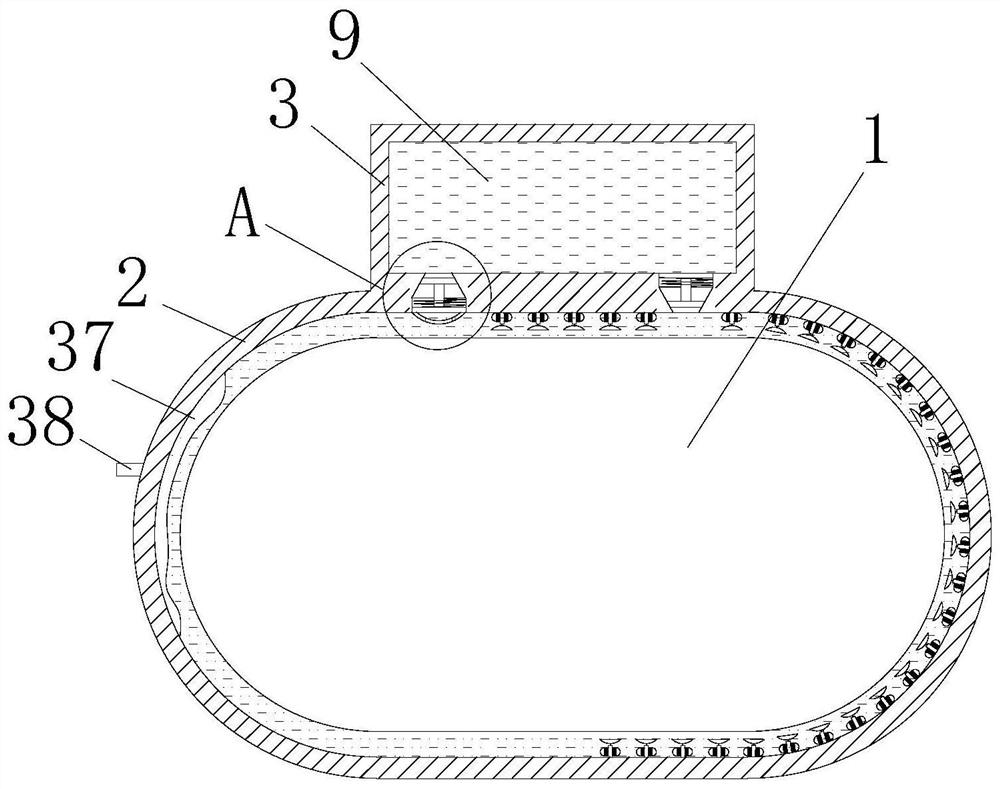

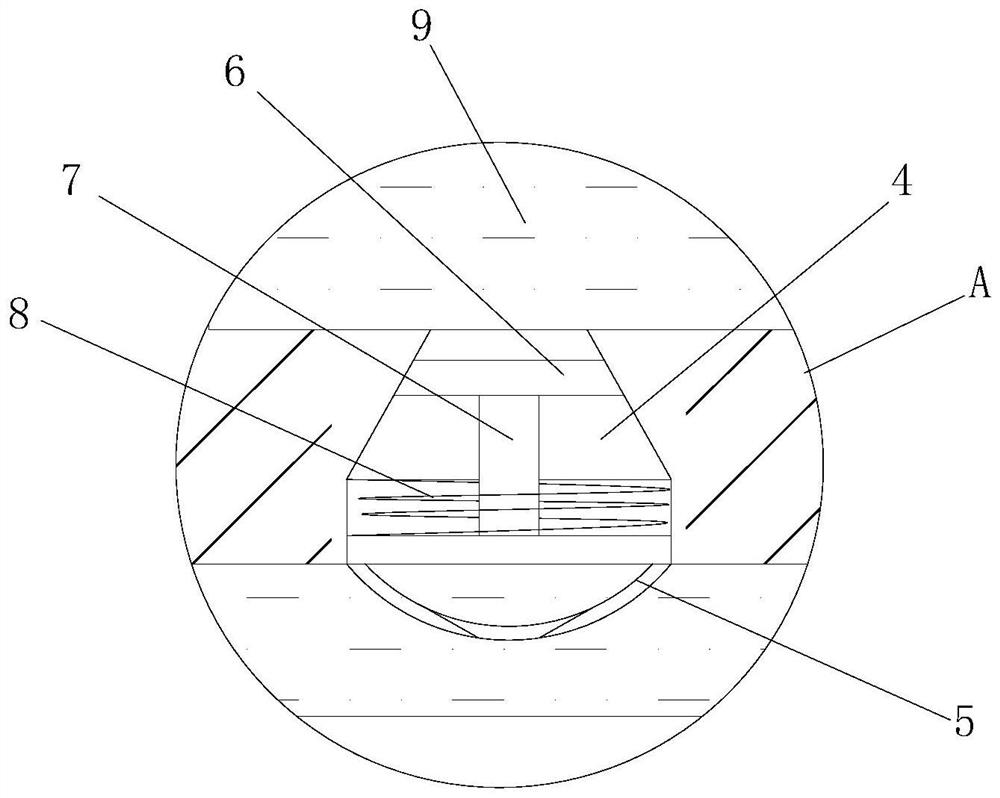

[0034] Example 1: Please refer to Figure 1-5 , a high-vacuum screw type vacuum pump, including a vacuum pump body 1, a casing 2 and a circulation box 3, the casing 2 is sleeved on the outer wall of the vacuum pump body 1, the inner wall of the casing 2 is hollowed out and is separated from the outer wall of the vacuum pump body 1 by five centimeters , the top surface of the shell 2 is fixedly connected with the circulation box 3, the circulation box 3 is a hollow rectangular body, the two sides of the bottom surface of the circulation box 3 are provided with flow holes 4, and the two flow holes 4 are connected with the inside of the shell 2, The circulation hole 4 is a circular platform hole, the side of the left circulation hole 4 with a small diameter faces upwards, and the right circulation hole 4 has a small diameter facing downwards, the inner wall of the circulation hole 4 is fixedly connected with a return spring A8, and the return spring A8 is not far away from the cir...

Embodiment 2

[0035] Example 2: Please refer to Figure 5 , on the basis of Embodiment 1, the front of the circulation box 3 is provided with a round hole and a rotating bearing is fixedly installed in the hole, and the inner ring of the rotating bearing is fixedly connected with a heat dissipation column 20. The material of the heat dissipation column 20 is copper material, and the heat dissipation column 20 is located at the outer wall of the circulation box 3 and is fixedly connected with a heat sink. Through the setting of the heat dissipation column 20, the good thermal conductivity of the copper material of the heat dissipation column 20 is used. After heat exchange between the heat dissipation column 20 and the cooling water 9 in the circulation box 3, the The heat is directly dissipated into the outside air, thereby improving the cooling efficiency of the cooling water 9 in the circulation box 3, ensuring the cooling effect of the cooling water 9 in the casing 2 after circulation, an...

Embodiment 3

[0036] Example 3: Please refer to Figure 6-10 , on the basis of Embodiment 2, the middle inner wall of the circulation box 3 is fixedly connected with a guide ring 21, the guide ring 21 is a hollow cylinder and both sides are provided with openings, the opening on the right side of the guide ring 21 is located at the lower right, and the guide ring 21 is located at the bottom right. The opening on the left side of the ring 21 is located at the upper left, and the cooling column 20 is located at the center of the guide ring 21. The outer wall of the cooling column 20 is fixedly connected with six slide plates 22 at equal intervals. The end of the slide plate 22 away from the cooling column 20 is attached to the inner wall of the guide ring 21. , the cooling water 9 that is squeezed and poured into the circulation box 3 will first be squeezed into the guide ring 21, and through the oblique opening in the guide ring 21, it will generate oblique propulsion to the slide plate 22, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com