Hydraulic control system of dual-clutch transmission

A technology of hydraulic control system and dual-clutch transmission, which is applied in the direction of transmission control, components with teeth, fluid pressure actuation device, etc., and can solve the problem of loss of transmission shift function and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

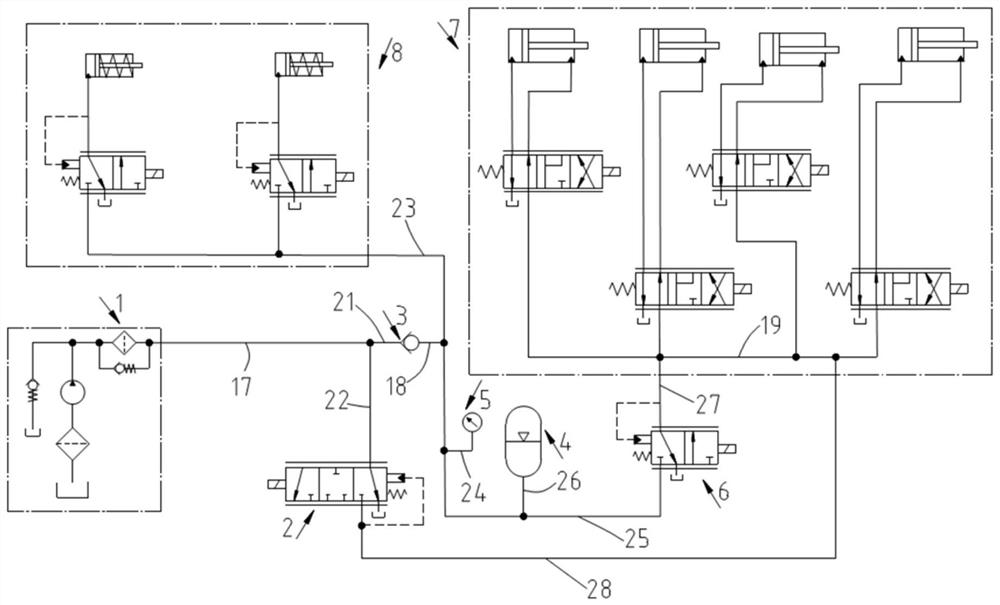

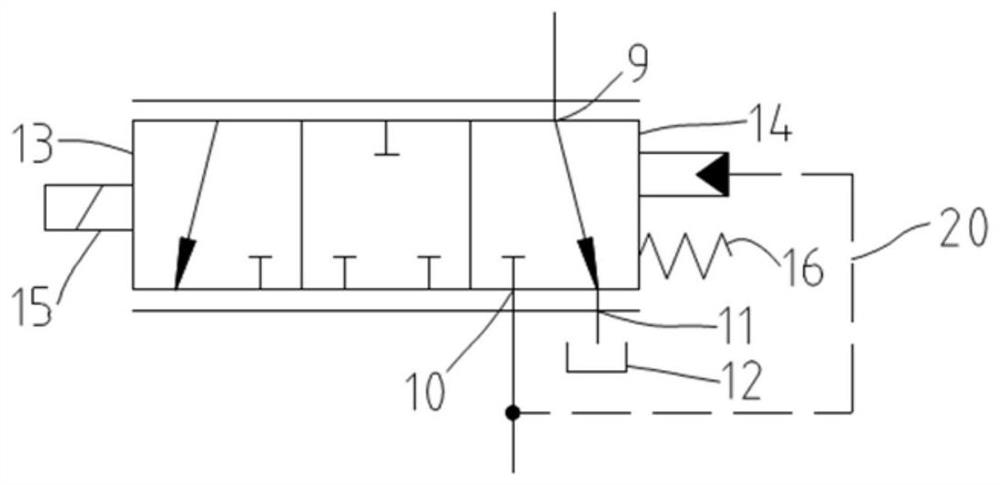

[0033] figure 1 It is the connection relationship diagram of the hydraulic control system of the dual-clutch transmission of the present embodiment, figure 2 Is the schematic diagram of the main oil pressure regulating valve.

[0034] The hydraulic control system of dual clutch transmission includes: oil supply device 1, main oil pressure regulating valve 2, check valve 3, accumulator 4, pressure sensor 5, shift pressure regulating valve 6, gear selection device 7 and clutch control device 8.

[0035] The main oil pressure regulating valve 2 is configured as a three-position three-way valve. The first interface 9 is connected to the oil supply device 1 through the second oil supply branch 22 and the oil supply hydraulic pipeline 17. The second interface 10 is connected to the oil supply device 1 through the second shift pressure The pipeline 28 and the gear selection device supply hydraulic pipeline 19 are connected to the gear selection device 7 , and the third interface 1...

Embodiment 2

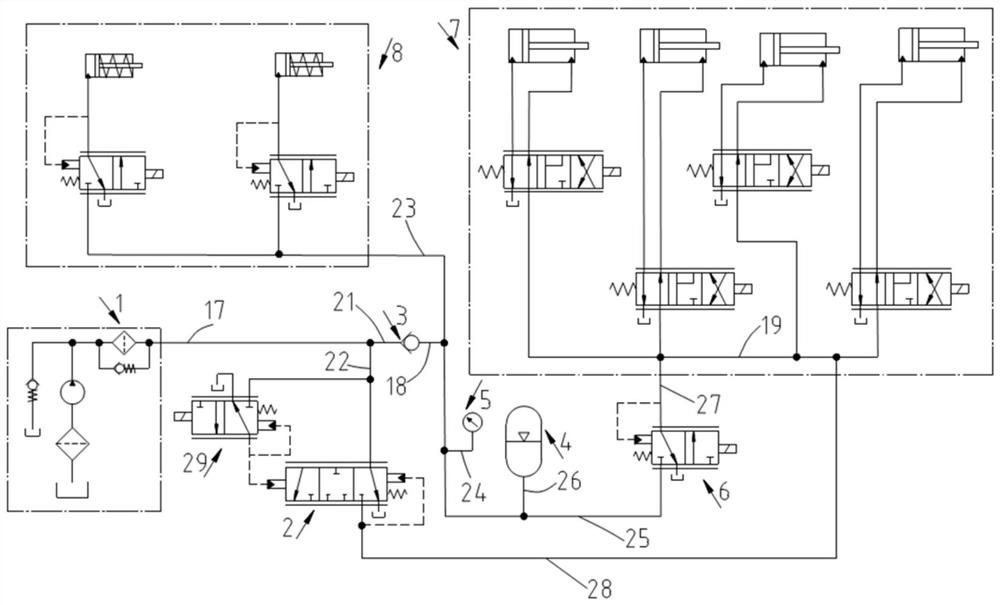

[0046] image 3 It is a connection relationship diagram of the hydraulic control system of the dual-clutch transmission according to the second embodiment of the present application. The difference from Embodiment 1 is that the main oil pressure regulating valve 2 is controlled by a pilot solenoid valve 29 . The pilot solenoid valve 29 is preferably a proportional pressure regulating valve. By adjusting the current size input to the pilot solenoid valve 29, the output oil pressure of the pilot solenoid valve 29 (that is, the force acting on the first valve surface 13) can be adjusted, and then The main oil pressure regulating valve 2 can be placed in the right position, the middle position or the left position according to the demand, and the oil pressure adjustment of the second shift pressure line 28 can also be realized when the main oil pressure regulating valve 2 is in the left position. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com