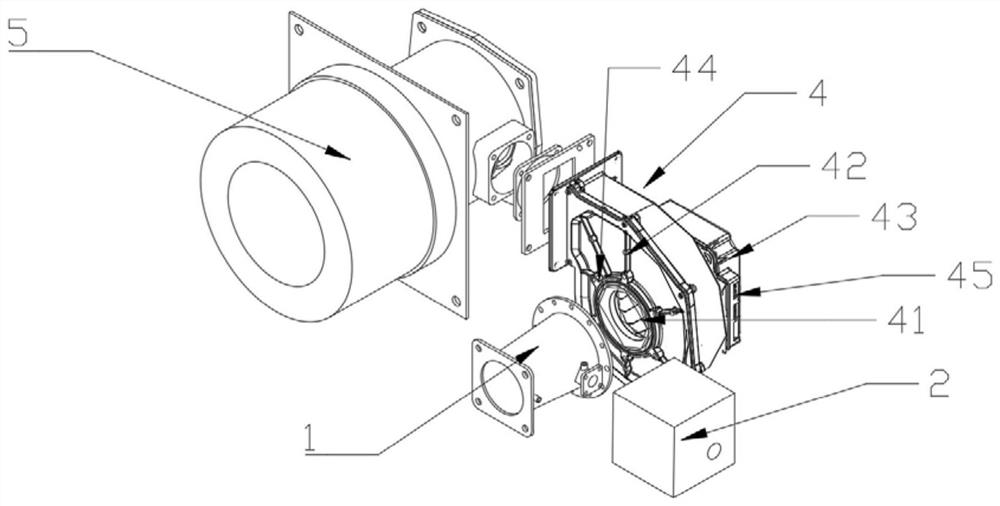

Full-premixing combustor and control system thereof

A burner and fully premixed technology, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of easy burning, large flow resistance of air-fuel mixture, and high fan pressure head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

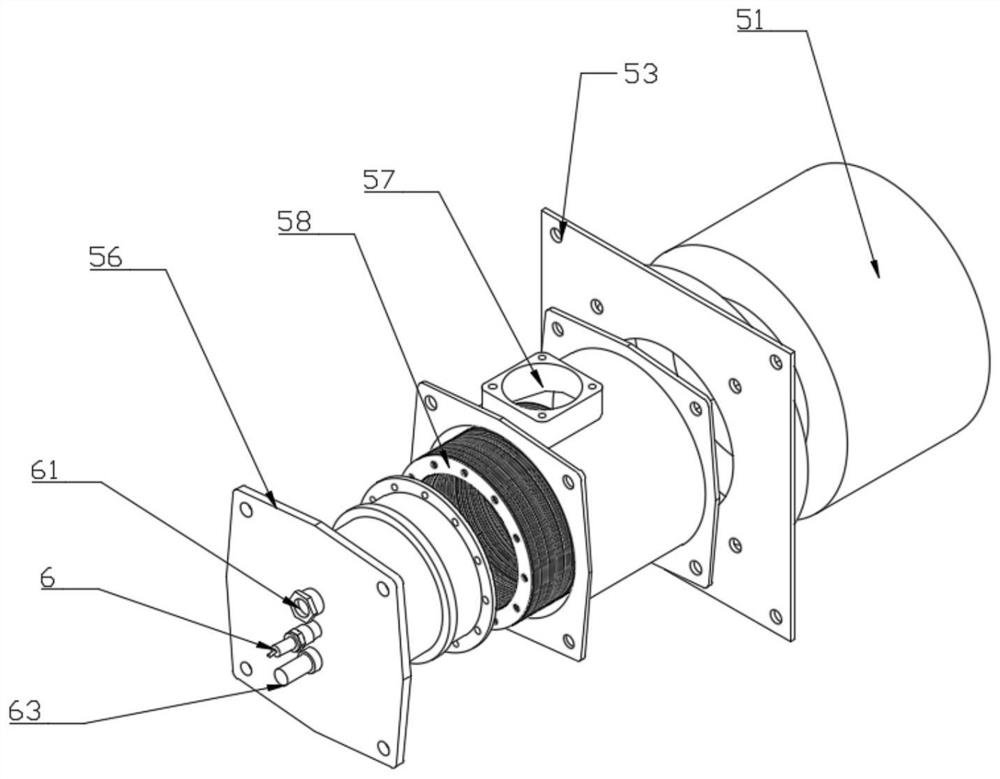

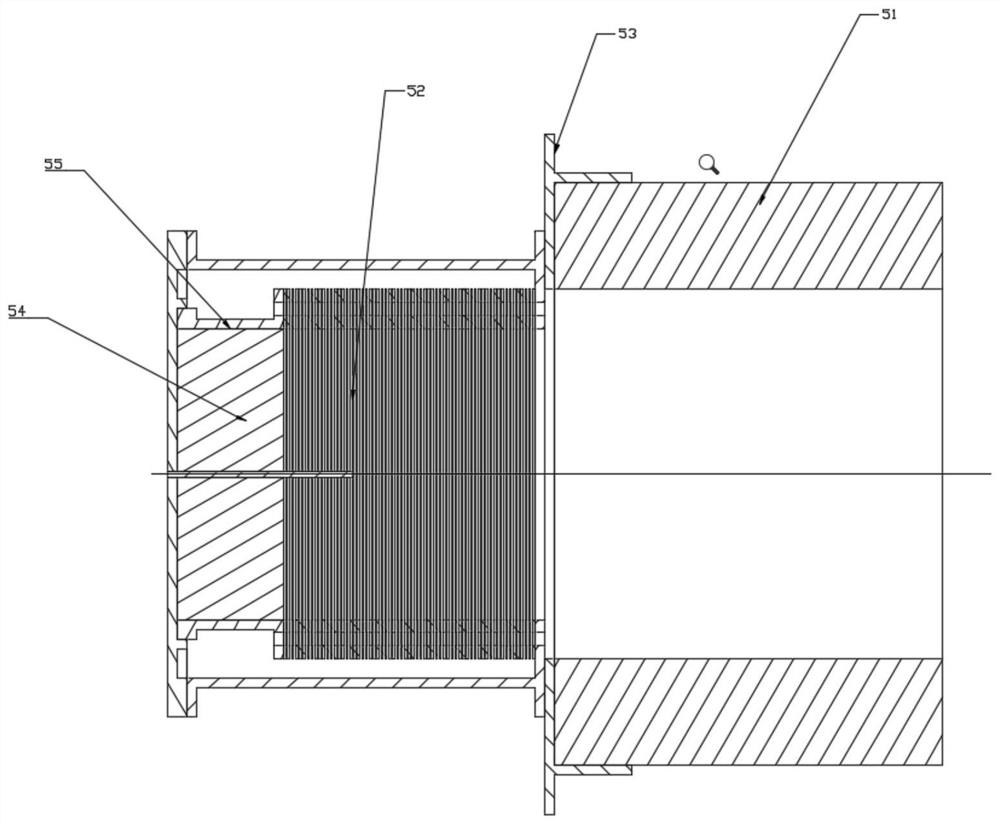

[0066] Head installation requirements: the head shell is designed to be bell-shaped, and the inside is a slit-shaped fire outlet formed by stacking metal rings with a thickness of 1mm. 1mm. The rings should be stacked neatly to avoid problems such as misalignment and uneven thickness. The front end of the annular cylinder is fixed to the fire outlet of the shell, and the rear is fixed to the designed bracket, which is embedded in the ring of the back cover of the shell. There should be a ceramic fiber board inside the bracket for heat insulation, so as to avoid the high temperature of the head burning and burn the back shell.

[0067] The head of the present invention is a side air intake, and the air-fuel mixture enters the burner head from the side of the shell, so the ignition pin and flame detector can be installed behind the burner head, and directly extend into the head to ignite. Avoid the problems of external collision and inconvenient transportation.

[0068] The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com