Array eddy current probe capable of actively removing electromagnetic coupling between adjacent coils

An electromagnetic coupling and eddy current probe technology, which is applied in the field of array eddy current probes, can solve the problems of low spatial resolution of the probe, affecting the accuracy and service life of the coil, and hindering the heat exchange of the energized coil in the cover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

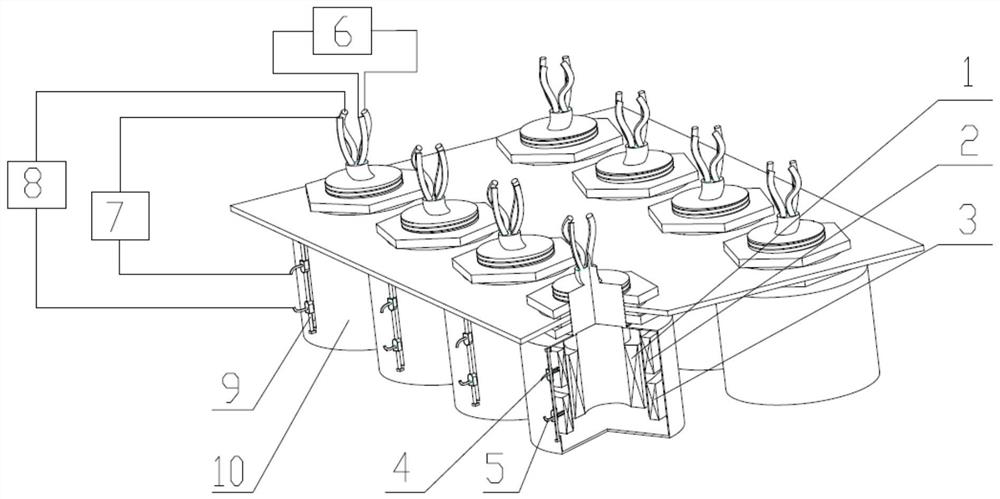

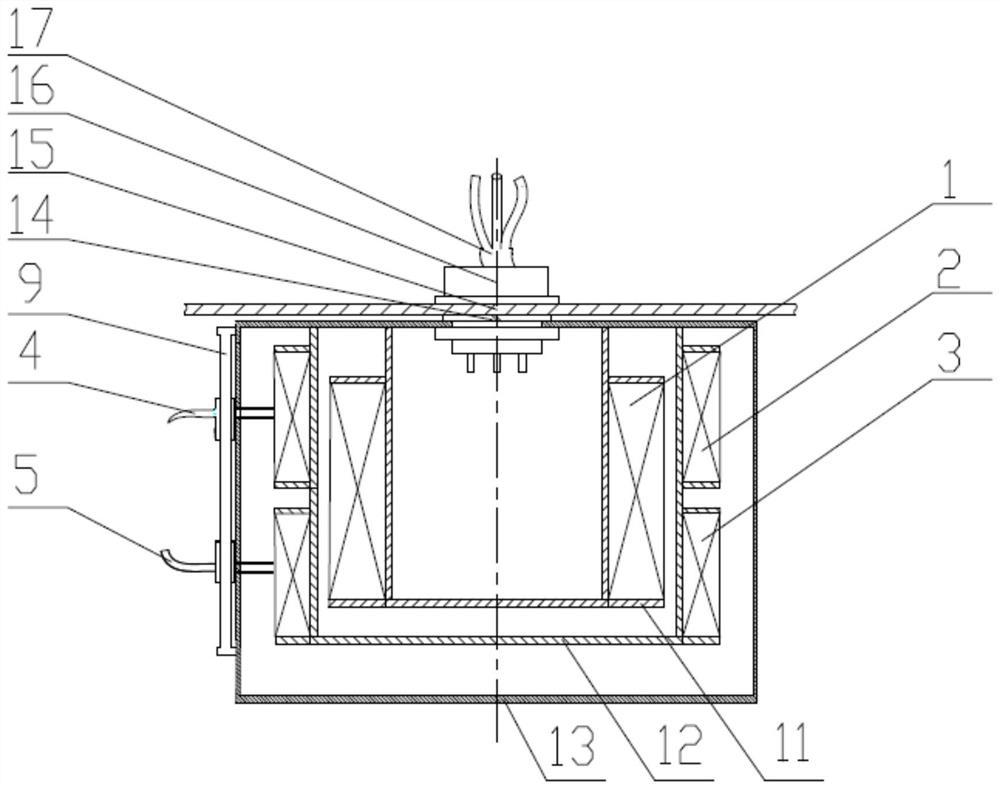

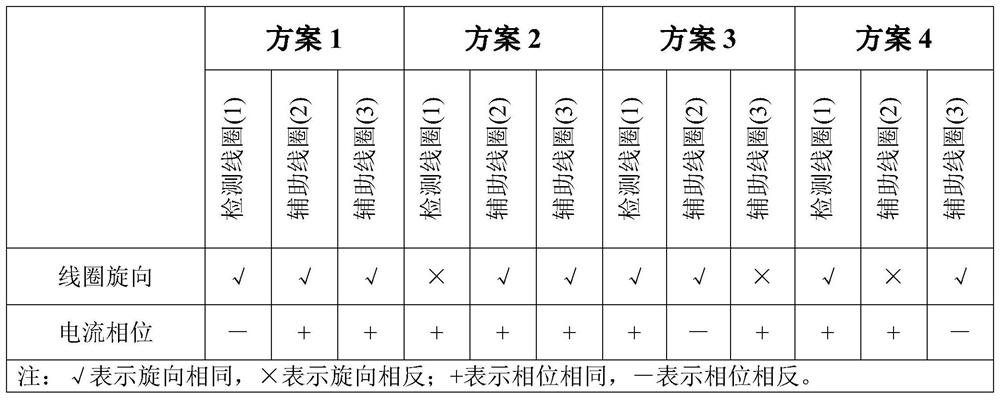

[0009] The overall structure diagram of the array probe designed by the present invention is as follows figure 1 Shown. The probe is composed of multiple independent sub-probes (10) separated by a certain distance from each other, each sub-probe has the same structure: the detection coil (1) is provided with an auxiliary coil (2) and an auxiliary coil (3), They are coaxial with the detection coil (1) and are respectively located at the upper and lower ends of the detection coil (1). The detection coil (1) is a hollow cylindrical coil, the auxiliary coil (2) and the auxiliary coil (3) are solenoid coils, and the detection coil (1), the auxiliary coil (2) and the auxiliary coil (3) are wound Line separation. The auxiliary coil (2) contacts and conducts with the metal sliding sheet (4), and the auxiliary coil (3) contacts and conducts with the metal sliding sheet (5). The two terminals of the detection coil (1) are connected to a loading circuit (6), and the auxiliary coil (2) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com