A test method for continuous withstand voltage of thin films

A test method and a technology of withstand voltage, which are applied in the direction of testing dielectric strength, measuring electricity, and measuring devices, can solve problems such as low adhesion between the film to be tested and the electrode plate, error in test results, and easy to ignore the diaphragm, etc., to achieve The effect of maintaining intermittent and stable testing, reducing waste of raw materials, and reducing the test area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

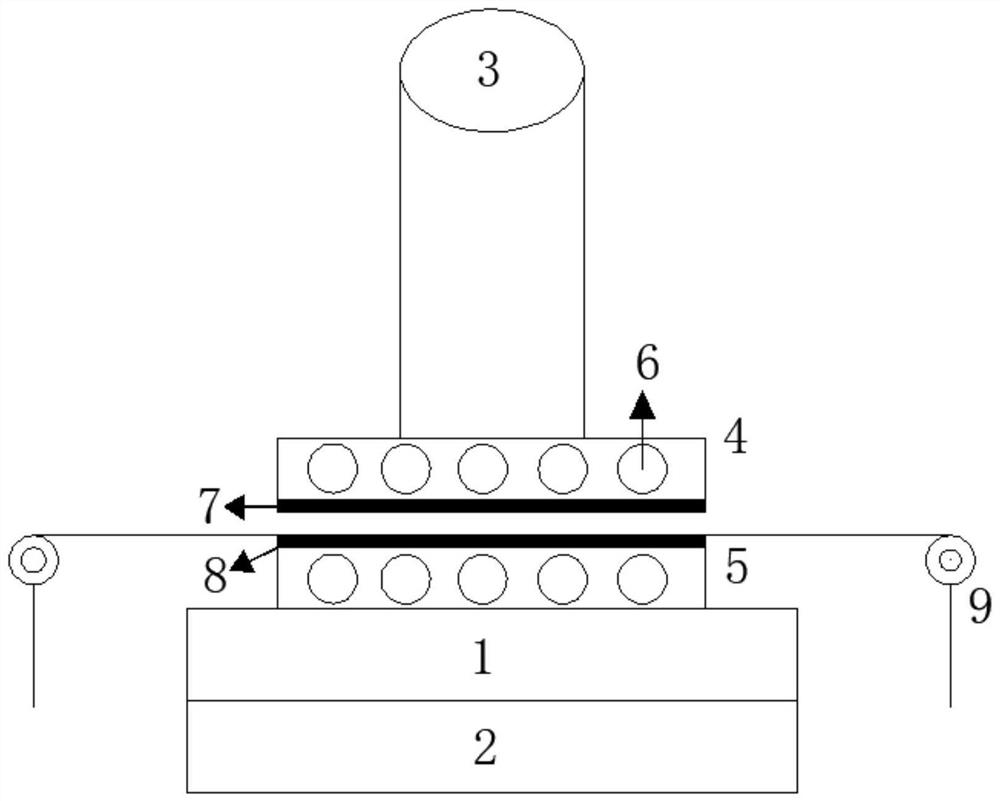

Embodiment 1

[0110] Program boosting method: use plates 4 and 5 with a size of 400*200*5 (length, width and thickness) mm, set the temperature of the upper and lower plates 4 and 5 to 25°C through the central control system 2, and the winding and unwinding device 9 runs intermittently The speed is 10m / min, the booster pump 3 exerts a pressure of 0.2MPa, and the programmed pressure increase rate is 500V / s. Open and start the test circuit successively, and open the rewinding and unwinding device 9 . The central control device reads the breakdown voltage value of each segment (400mm) of diaphragm (12 micron PE base film) in real time for 1 minute and records the data in the table below, unit (V).

[0111] 1350 1560 1216 1420 1320 1250 1585 1524 1462 1344 1660 1364 1660 1106 1130 1231 1431 1530 1206 1337 1402 1430 1060 1615 1422

Embodiment 2

[0113] Program boosting method: use plates 4 and 5 with a size of 400*200*5 (length, width and thickness) mm, set the temperature of upper and lower plates 4 and 5 to 25°C through the central control system 2, and control the winding and unwinding device 9 intermittently The walking speed is 10m / min, the booster pump 3 exerts a pressure of 5MPa, and the programmed pressure increase rate is 500V / s. Open and start the test circuit successively, and open the rewinding and unwinding device 9 . The central control device reads the breakdown voltage value of each segment (400mm) of diaphragm (12 micron PE base film) in real time for 1 minute and records the data in the table below, unit (V).

[0114] 550 395 485 350 256 360 355 439 462 352 360 423 335 306 460 403 523 324 440 361 532 351 295 387 286

Embodiment 3

[0116] Program boosting method: use plates 4 and 5 with a size of 400*200*5 (length, width and thickness) mm, set the temperature of upper and lower plates 4 and 5 to 25°C through the central control system 2, and control the winding and unwinding device 9 intermittently The walking speed is 10m / min, the booster pump 3 exerts a pressure of 0.1KPa, and the programmed pressure increase rate is 500V / s. Open and start the test circuit successively, and open the rewinding and unwinding device 9 . The central control device reads the breakdown voltage value of each segment (400mm) of diaphragm (12 micron PE base film) in real time for 1 minute and records the data in the table below, unit (V).

[0117] 1455 1460 1536 1620 1420 1351 1485 1501 1434 1452 1356 1402 1320 1158 1230 1241 1351 1430 1316 1437 1402 1430 1060 1615 1422

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com