Method for detecting pseudo soldering of power battery module

A power battery and detection method technology, which is applied in the direction of electrical connection testing, measuring electricity, measuring devices, etc., can solve the problems of affecting accuracy, difficult charging and discharging at high rates, and unrecognizable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

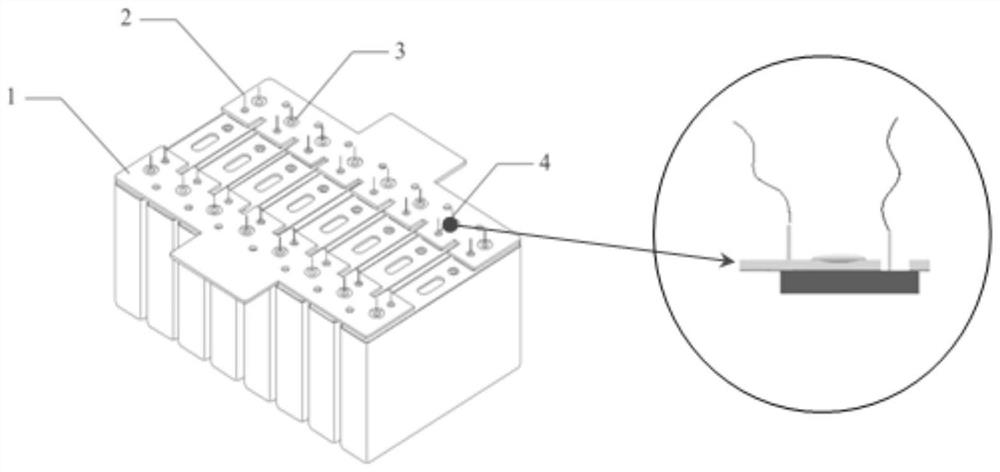

[0027] Please refer to figure 1 As shown, the present invention discloses a method for detecting false welding of a power battery module, which specifically includes the following steps:

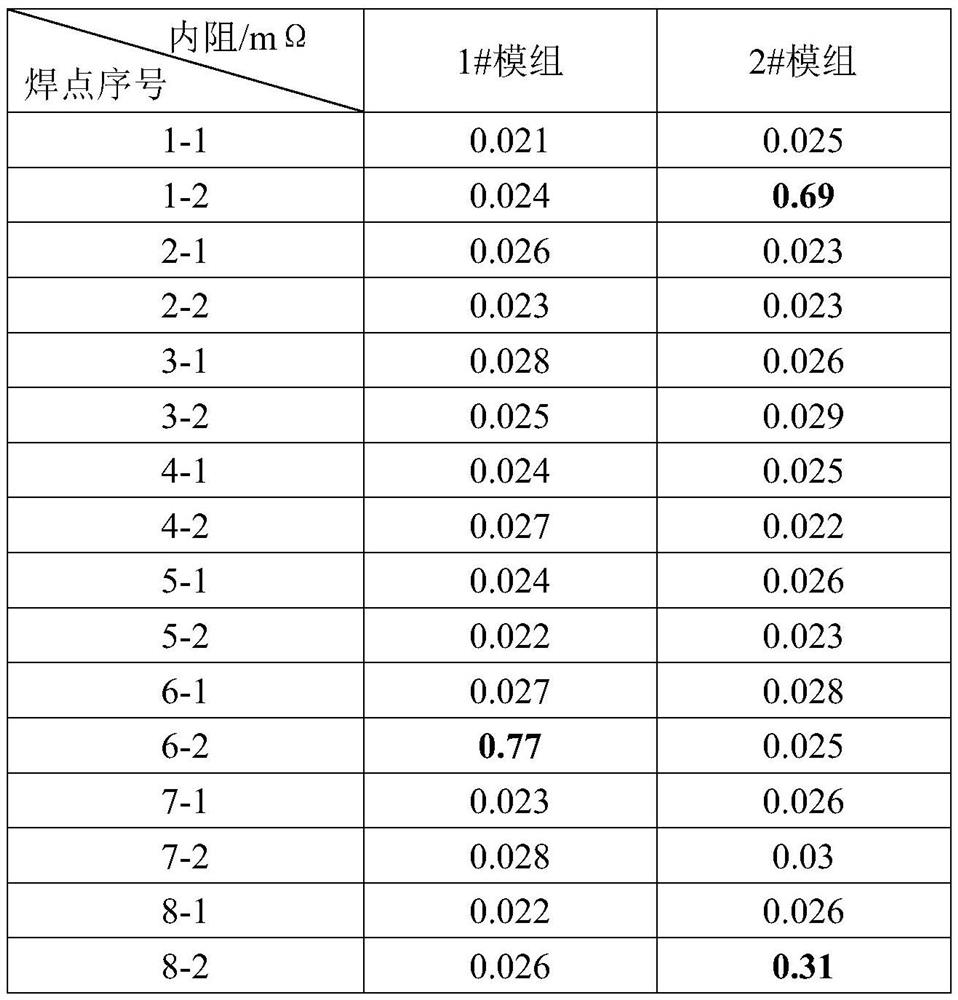

[0028] 1) Select two 8P modules that obviously have virtual solder joints through visual observation and stress inspection; number the solder joints 3; design a circular through hole 4 with an inner diameter greater than 1mm at each soldering position of the bus bar 1, and pass through The position of the hole 4 is within the contact range between the bus bar 1 and the battery pole; the material of the bus bar 1 is aluminum;

[0029] 2) Weld the bus bar 1 and the pole using laser welding to make a module;

[0030] 3) Use an internal resistance tester to perform a resistance test after welding. The internal resistance tester meets the resolution NDC>5 and accuracy requirements %GRR<10% of the measurement system. During the test, the probe 2 at one end is lapped on the welding point 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com