Intelligent power module

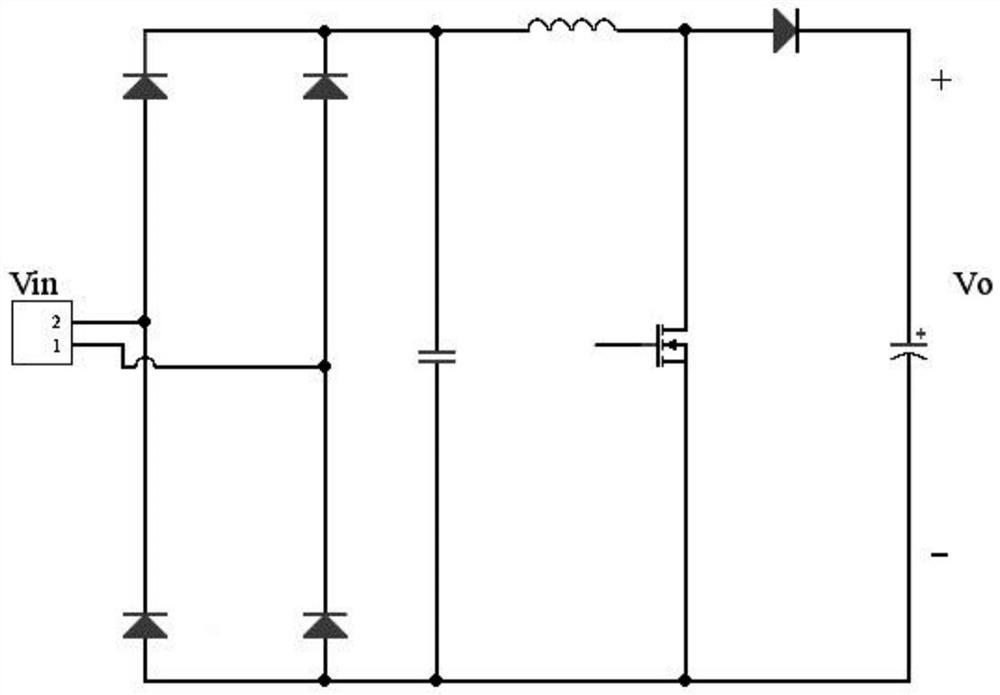

A technology of intelligent power modules and diodes, which is applied in the direction of output power conversion device, conversion of AC power input to AC power output, conversion of AC power input to DC power output, etc., which can solve the problems of increasing process difficulty and cost, large PFC current, Difficulties in structural design and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

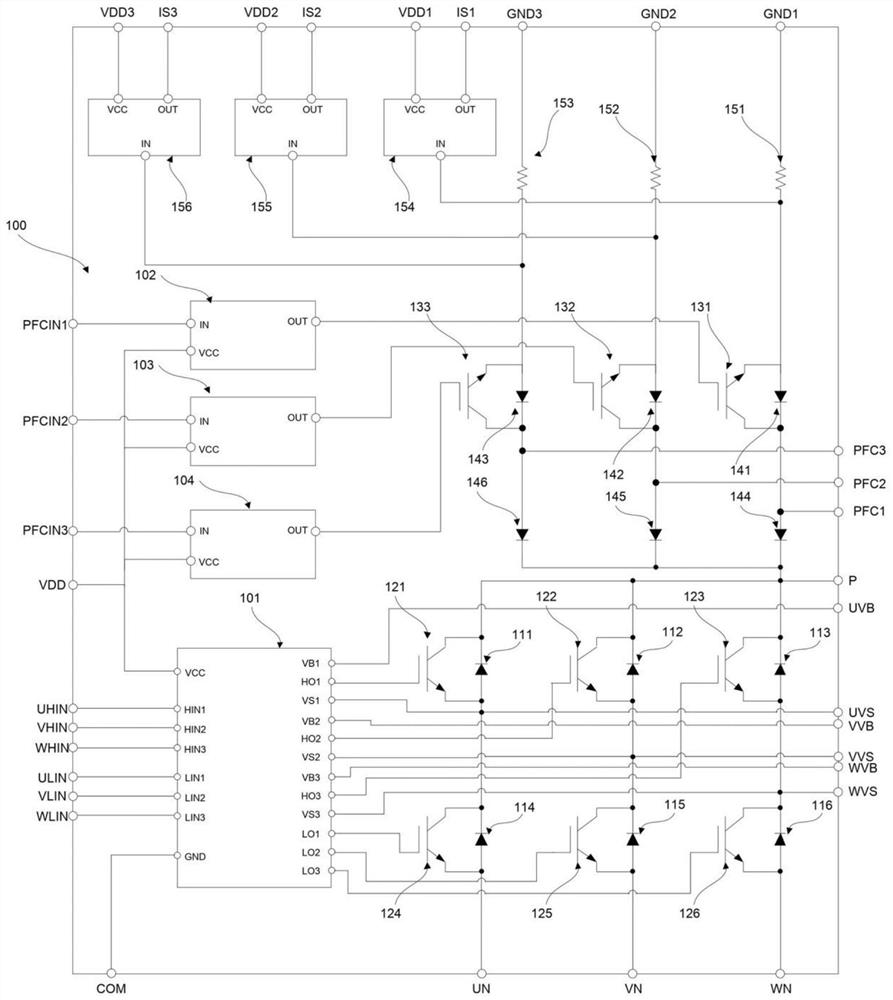

[0018] see figure 2, the present invention proposes an intelligent power module 100, including a HVIC (High Voltage Integrated Circuit, high-voltage integrated circuit) tube 101, a three-phase bridge inverter circuit, a first drive IC tube 102, a second drive IC tube 103, a third drive IC tube 103, and a third drive IC tube 103. IC tube 104, first switch tube 131, second switch tube 132, third switch tube 133, first diode 141, second diode 142, third diode 143, fourth diode 144, The fifth diode 145, the sixth diode 146, the first detection resistor 151, the second detection resistor 152, the third detection resistor 153, the first comparator 154, the second comparator 155 and the third comparator 156; The HVIC tube is connected to the three-phase bridge inverter circuit for receiving external control signals and controlling each switching device of the three-phase bridge inverter circuit to complete the inversion; A PFC control input terminal PFCIN1, the output terminal of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com