Multilayer flexible circuit board and manufacturing method thereof

A technology of flexible circuit boards and manufacturing methods, which is applied in the directions of multilayer circuit manufacturing, printed circuit manufacturing, chemical instruments and methods, etc., and can solve problems such as low yield rate, many processes, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Embodiment: the following are specific embodiments and comparative examples of the present invention, and test results thereof, see Table 1 and Table 2, and the unit of thickness of each layer in the table is μm:

[0054] Table 1:

[0055]

[0056] Table 2

[0057]

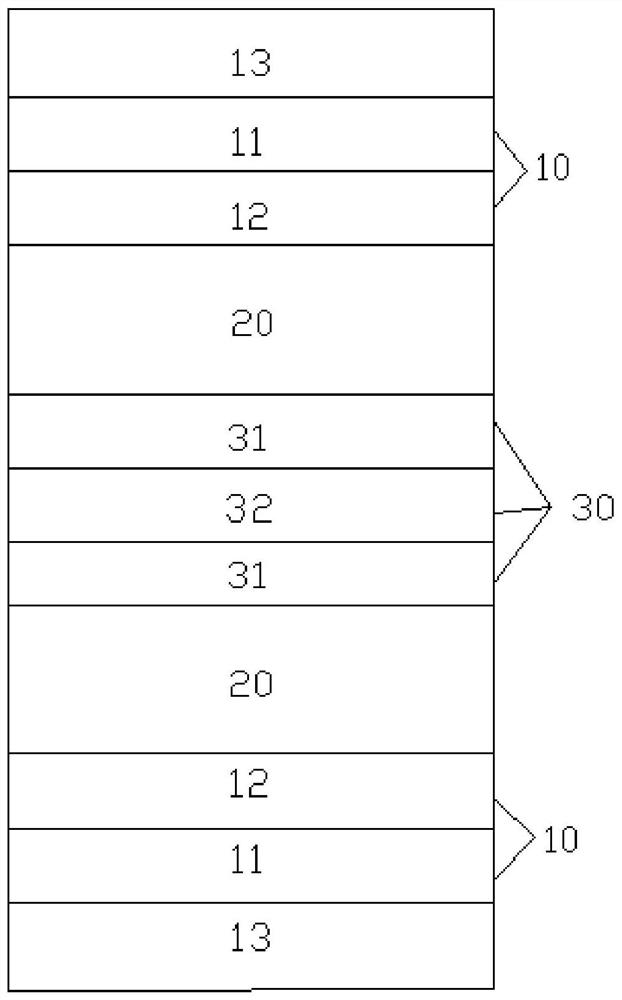

[0058] Embodiment 1-5 is a four-layer board, and the preparation method is as follows:

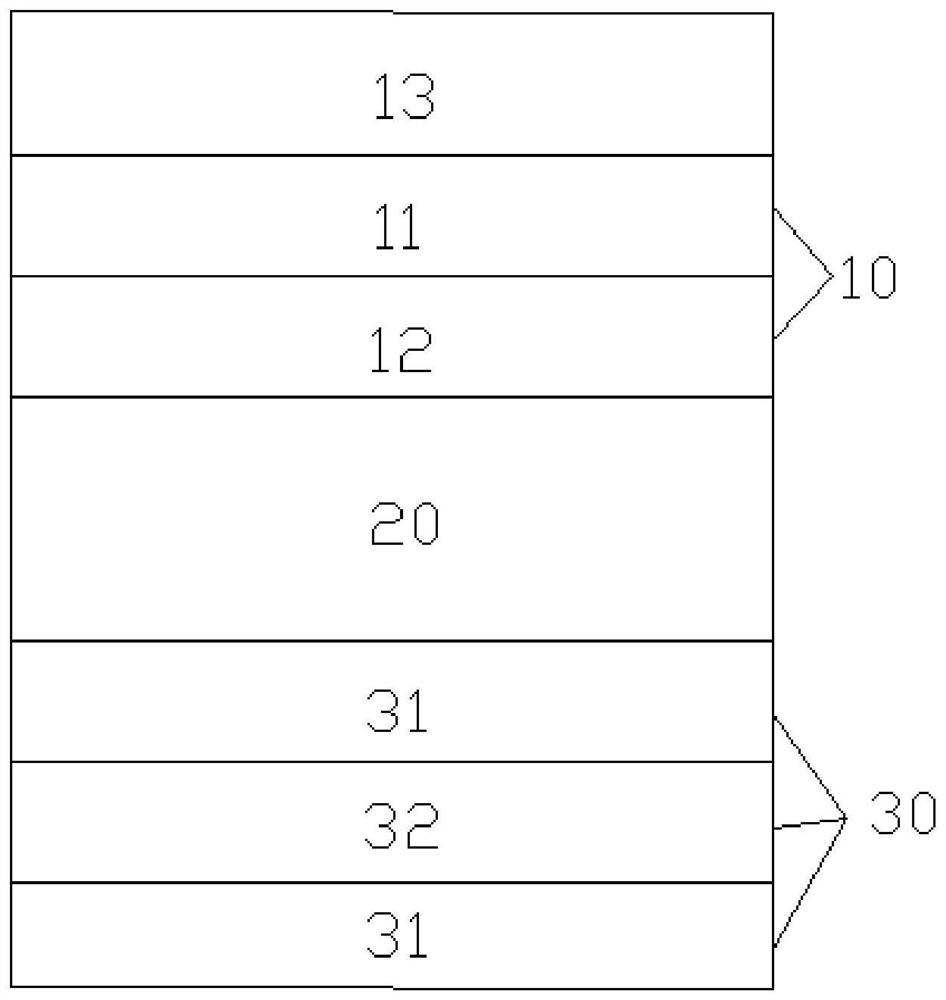

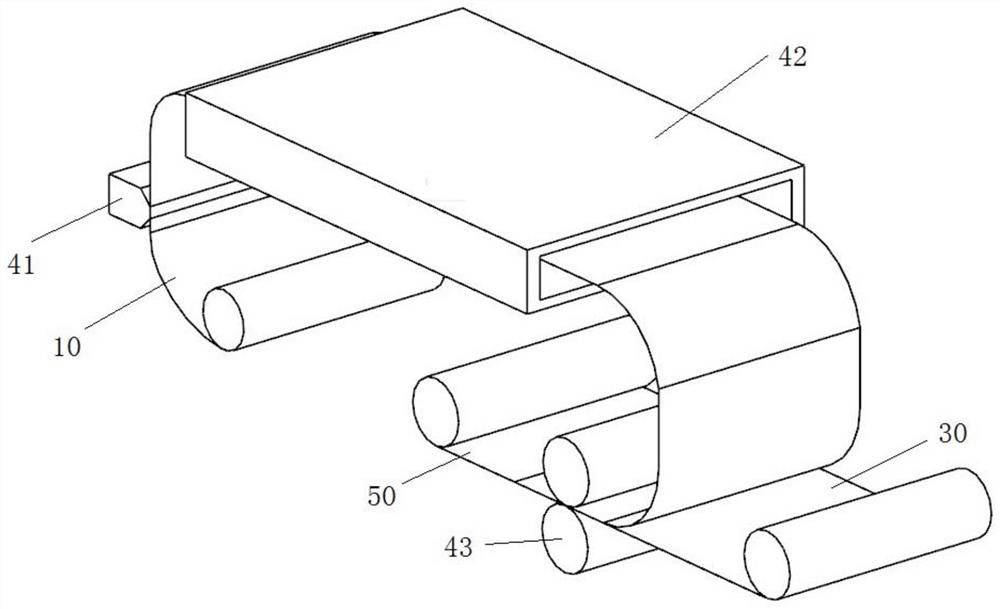

[0059] Step 1: Take a single-sided adhesive-free copper foil substrate 10, and laminate the PET film on the side of the first copper foil layer 11 away from the first polyimide layer 12, wherein the lamination condition is a lamination temperature of 50-120°C , The pressing pressure is 1-2kg and the pressing speed is 3-20rpm;

[0060] Step 2: Carry out roll-to-roll etching of the double-sided adhesive-free copper foil substrate 30 to form double-sided circuits, and obtain the etched double-sided adhesive-free copper foil substrate;

[0061] Step 3: Coating a layer of adhesive layer 20 on the first polyimide lay...

Embodiment 6-8

[0067] Embodiment 6-8 is a three-layer board, and the preparation method is as follows:

[0068] Step 1: Take a single-sided adhesive-free copper foil substrate 10, and laminate the PET film on the side of the first copper foil layer 11 away from the first polyimide layer 12, wherein the lamination condition is a lamination temperature of 50-120°C , The pressing pressure is 1-2kg and the pressing speed is 3-20rpm;

[0069] Step 2: Carry out roll-to-roll etching of the double-sided adhesive-free copper foil substrate 30 to form double-sided circuits, and obtain the etched double-sided adhesive-free copper foil substrate;

[0070] Step 3: Coating a layer of adhesive layer 20 on the first polyimide layer 12 of the single-sided adhesive-free copper foil substrate 10 laminated with PET film, and pre-baking in a coating oven for a short time to obtain the glue coating After the single-sided copper foil substrate;

[0071] Step 4: Press the coated single-sided copper foil substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Release force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com