Hydrogel, cement paste and method for curing harmful metal ions by using well cementation cement

A technology for metal ions and cementing slurry, which is applied in the field of cement slurry and cementing cement to solidify harmful metal ions and hydrogels, can solve problems such as secondary environmental pollution, reduce leaching, avoid adverse effects, and ensure basic performance. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

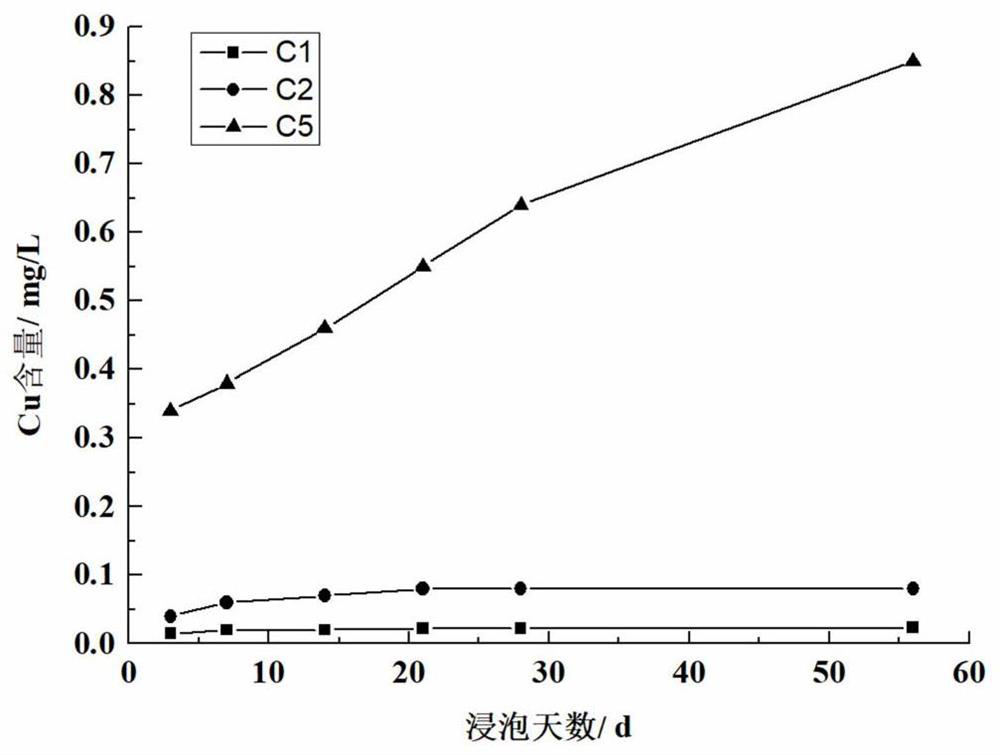

[0030] Embodiment 1 A method for solidifying harmful metal ions with cement

[0031] Prepare 200g of 10000mg / L copper sulfate solution, then add 40g of AMPS, 0.4g of MBA, and 0.8g of ammonium persulfate, stir and dissolve evenly, and polymerize at 75°C for 4h to form a hydrogel. Take 90g of hydrogel and add it to the slurry mixing water, and prepare cement slurry according to the following formula: G grade oil well cement 600g + sulfonic acid group and carboxylic acid group copolymerization type fluid loss reducer 15g + sulfonated aldehyde and ketone type dispersant 3g + 90g hydrogel +150g water. The mass ratio of hydrogel and water to cement mass is 0.4. The cement slurry is recorded as C1.

Embodiment 2

[0032] Embodiment 2 A method for solidifying harmful metal ions with cement

[0033] Prepare 200g of 10000mg / L copper sulfate solution, then add 80g of AMPS, 0.4g of MBA, and 0.8g of ammonium persulfate, stir and dissolve evenly, and polymerize at 75°C for 4h to form a hydrogel. Take 120g of hydrogel and add it to the slurry mixing water, and prepare cement slurry according to the following formula: G grade oil well cement 600g + sulfonic acid group and carboxylic acid group copolymerization type fluid loss reducer 15g + sulfonated aldehyde and ketone type dispersant 3g + 120g hydrogel +120g water. The mass ratio of hydrogel and water to cement mass is 0.4. The cement slurry is recorded as C2.

Embodiment 3

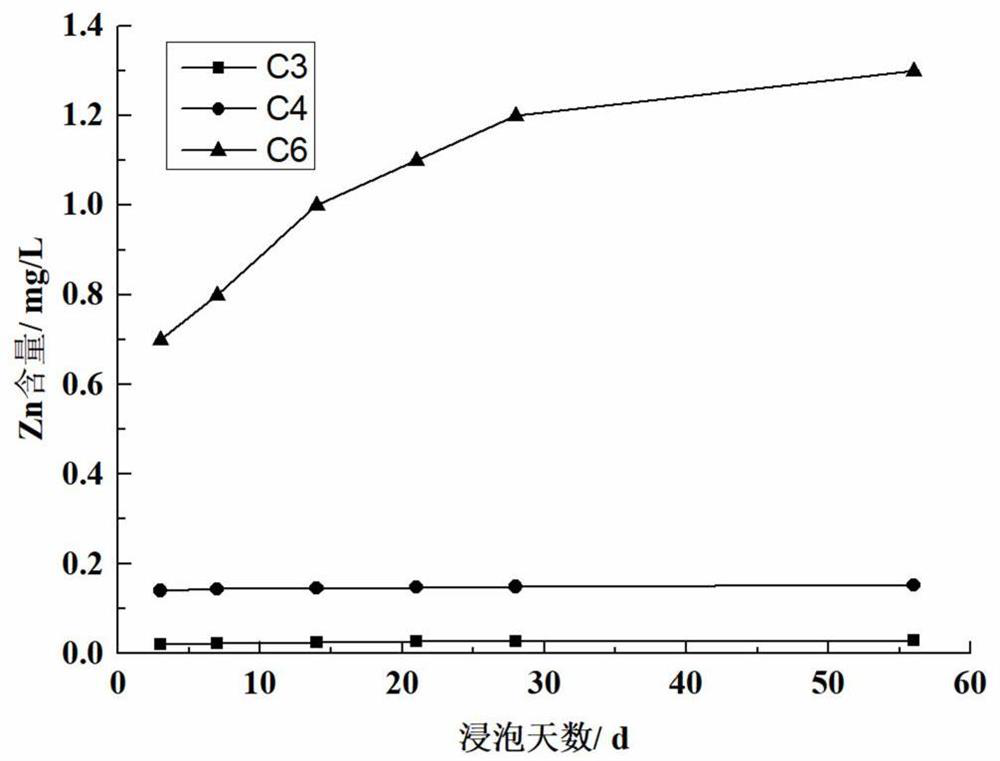

[0034] Embodiment 3 A method for solidifying harmful metal ions with cement

[0035] Prepare 200g of 10000mg / L zinc sulfate solution, then add 40g of AA, 0.4g of MBA, 0.8g of ammonium persulfate, stir and dissolve evenly, and polymerize at 70°C for 5h to form a hydrogel. Take 90g of hydrogel and add it to the slurry mixing water, and prepare cement slurry according to the following formula: G grade oil well cement 600g + sulfonic acid group and carboxylic acid group copolymerization type fluid loss reducer 15g + sulfonated aldehyde and ketone type dispersant 3g + 90g hydrogel +150g water. The mass ratio of hydrogel and water to cement mass is 0.4. The cement slurry is recorded as C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com