Production method for aluminized steel plate plating material aluminum-silicon alloy

A technology of aluminum-magnesium alloy and silicon alloy materials, which is applied in the field of aluminum-silicon alloy materials for coating aluminum-plated steel sheets, can solve the problems of split metal structure, decline in material mechanical properties, and uneven pits and pits, so as to reduce surface tension, The effect of prolonged modification time and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

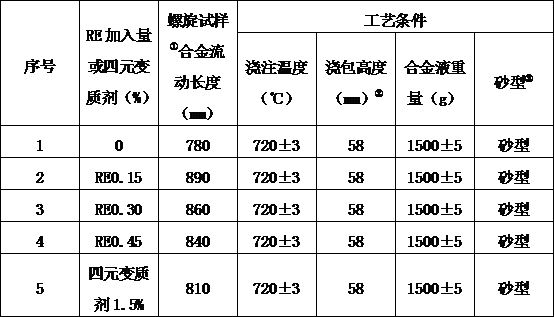

[0037] The hot-dip aluminum-silicon alloy material provided by the invention mainly contains Si: 6-13%; RE: 0.02-0.3%; Ti: 0.02-0.5%; B: 0.01-0.25%, and the balance is Al and unavoidable impurities (such as Fe) content. In order to describe the technical solution of the present invention to those skilled in the art, the numerical values listed in Table 1 below are the specific numerical values of some preferred embodiments that have been selected and achieved better technical effects within the protection scope of the present invention. However, the content of each component of the present invention is not limited to the numerical values listed in Table 1. For those skilled in the art, they can be reasonably summarized and deduced on the basis of the numerical range listed in Table 1.

[0038] Table 1: The mass percentage (%) of each component in the total weight

[0039] Si RE Ti B Al Impurities (Fe, etc.) 11.0 0.1 0.15 0.038 margin ≤0.03 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com