Automatic grout spraying facility for laying wet masonry stone retaining wall

A technology for equipment installation and stone barriers, which is applied in construction and building construction, etc., can solve the problems of increasing work difficulty and workload, higher requirements for experience and physical strength, and greater difficulty in equipment maintenance, so as to reduce maintenance costs and reduce costs. Difficulty, ensure work efficiency, and reduce the effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

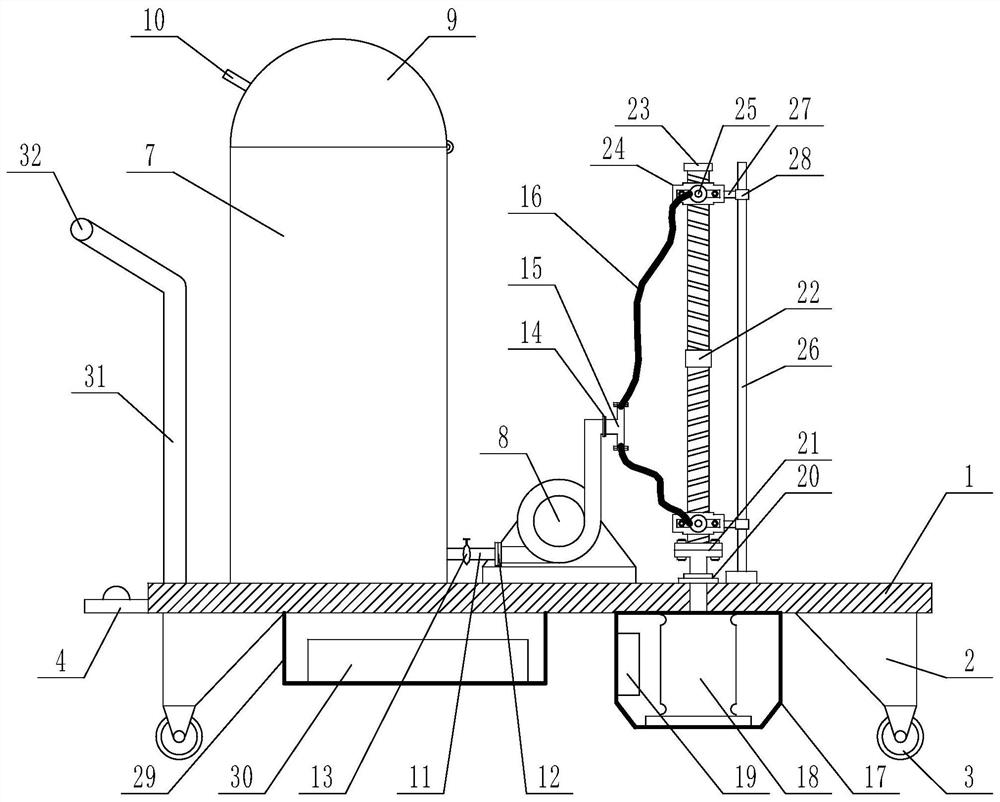

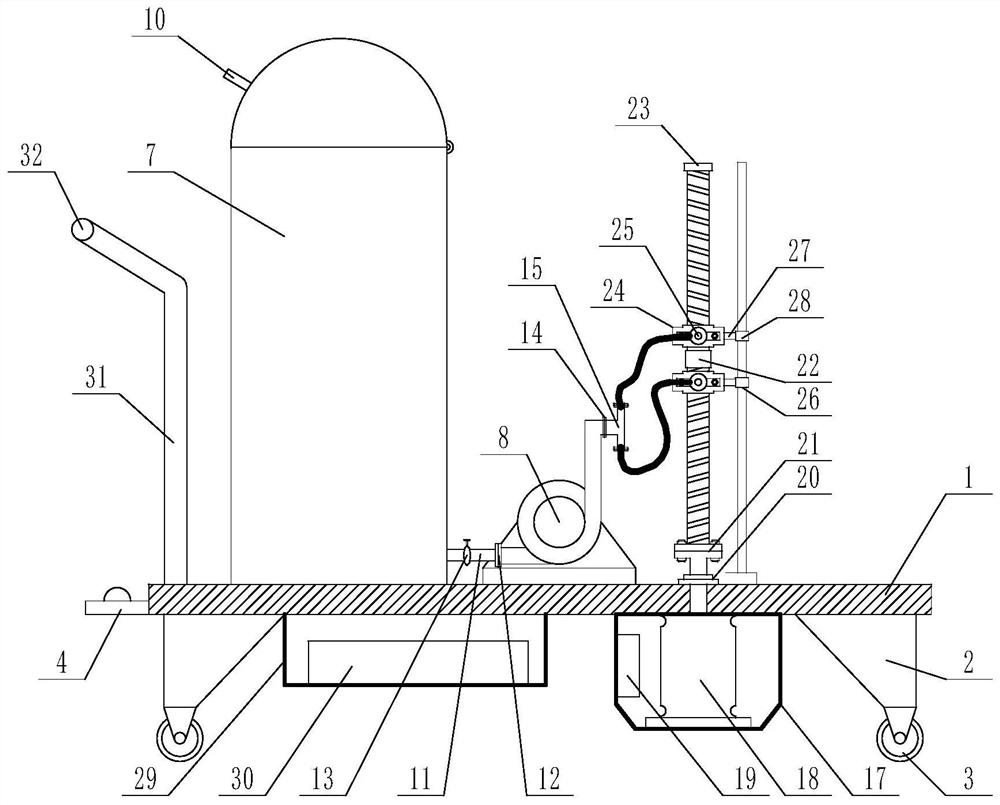

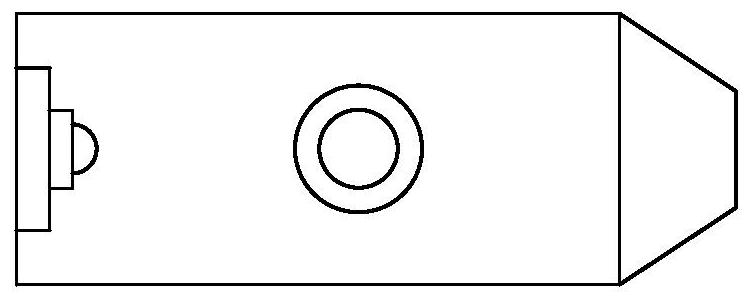

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown in -4, the inventive point of the present application is to fix the mounting bracket 2 at the four corners of the lower surface of the mounting plate, the universal wheel 3 is installed at the lower end of the bracket, and the handrail and the pedal 4 are fixedly installed on one side of the mounting plate. The pedal is provided with a spray pump foot switch 5 and a servo motor foot switch 6, and a paint storage tank 7 and a spray pump 8 are fixedly installed on the surface of the mounting plate, and the paint storage tank is a cylindrical tank body. The top of the storage tank is provided with a button cover 9, which is connected to the top opening of the paint storage tank through a hinge structure, the button cover is provided with a handle 10, and the lower end of the paint storage tube is provided with a stainless steel tube 11. The stainless steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com