Method for extracting gas and preventing and extinguishing fire by using composite drill hole

A technology for gas drainage and fire prevention, which is applied in drilling equipment and methods, gas discharge, earthwork drilling and mining, etc. It can solve the problems of inability to make full use of drainage drilling holes, damage of pre-buried pipelines, and influence on the normal advancement of the working face, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

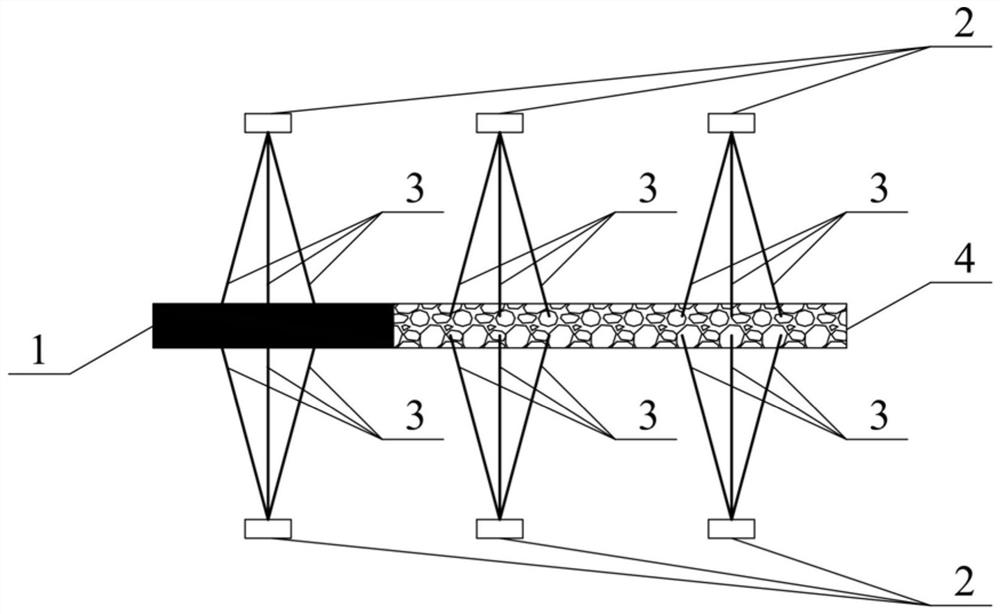

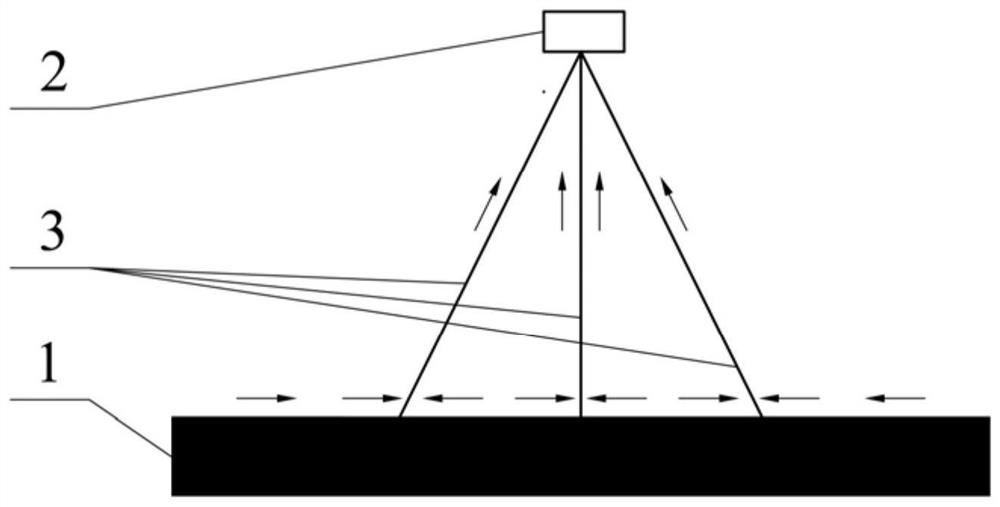

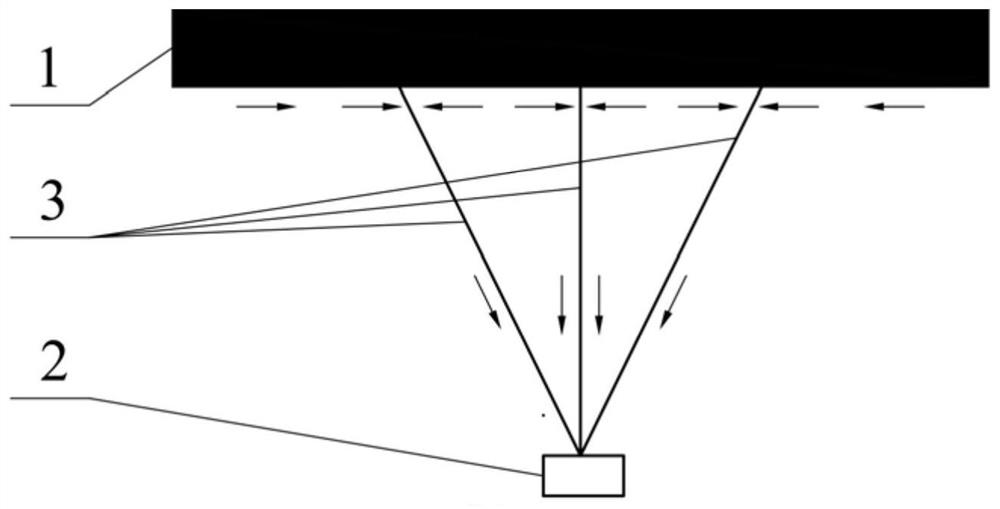

[0022] The present invention is suitable for gas extraction and fire prevention and extinguishing in high-gas spontaneous combustion coal seams, and the specific embodiments of the present invention are described below:

[0023] The specific method is as follows: a drilling site (2) is set every 20m in the roof or floor rock roadway of the high-gas spontaneous combustion coal seam (1), and dense composite drilling (3) is constructed in each 10m area before and after the coal seam (1). The final hole spacing in the coal seam (1) is 4m×4m. The azimuth and inclination of the composite borehole (3) are determined by the position of the drilling site (2), the distance between the final holes and the position of the coal seam (1), so as to carry out construction.

[0024] In concrete implementation, utilize composite drilling (3) to carry out coal mine disaster prevention and control according to the following stages:

[0025] The first stage: before the coal seam (1) is mined, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com