Multi-pass light spot laser emitter

A laser emitter and light spot technology, applied in the direction of instruments, optics, optical components, etc., can solve problems such as low measurement accuracy, lower hit rate of laser emitters, and difficult selection of detection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

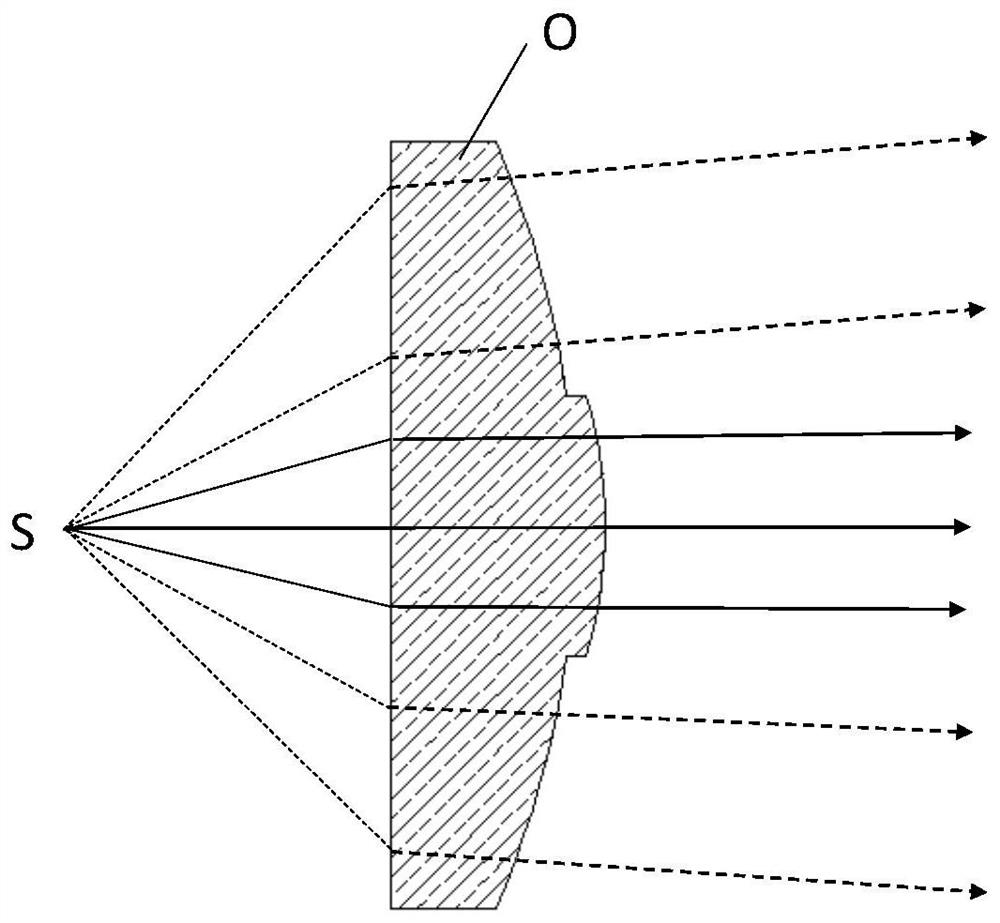

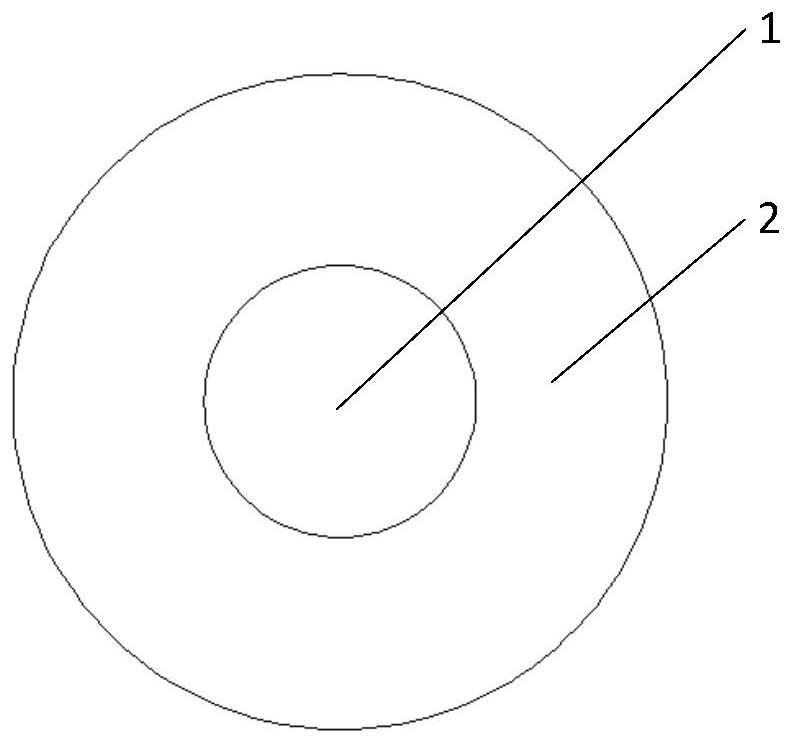

[0023] A laser emitter with multiple passes of light spots includes a laser source S, a lens O, and the lens O contains a plurality of ring-shaped lens areas, such as figure 1 and 2 The lens O in the lens is two ring-shaped lens areas, namely the ring-shaped lens area 1 and the ring-shaped lens area 2. The main optical axes of each ring-shaped lens area are coincident, and the focal lengths are different, so that under the irradiation of a laser emitter, the light passes through different When the lens area, the divergence angle is different.

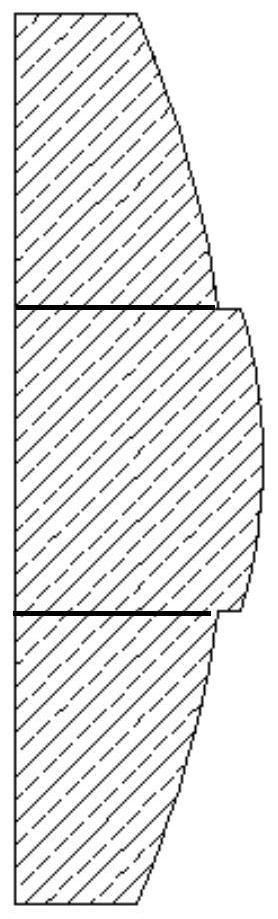

[0024] The lens O can be made of plastic, resin or glass material. When manufacturing the lens, it can be integrally formed, that is, the final shape can be made into a mold, or a larger lens can be prepared through the mold, and then processed to produce different focal lengths. ring lens area, figure 1 The one shown is integrally formed; in addition, the method of assembling can also be adopted, that is, for the convenience of manuf...

Embodiment 2

[0027] A specific structure of a laser emitter with a multi-pass spot, including a laser source S, a lens O, and the lens O includes a plurality of lens areas, and the lens areas are composed of a plurality of fan-shaped areas, and the fan-shaped areas are located perpendicular to the main beam axis of the lens section, and the apex of the fan-shaped area coincides with the intersection of the principal optical axis and the lens section, such as Figure 5 The lens O in the lens is two fan-shaped lens areas, which are respectively fan-shaped lens area 3 and fan-shaped lens area 4. The main optical axes of each fan-shaped lens area are coincident, and the focal lengths are different, so that under the irradiation of a laser emitter, the light passes through different When the lens area, the divergence angle is different.

[0028] The lens O can be made of plastic, resin or glass material. When manufacturing the lens, it can be integrally formed, that is, the final shape can be m...

Embodiment 3

[0031] A specific structure of a laser emitter with a multi-pass spot, including a laser source S, a lens O, and the lens O includes a plurality of lens areas, and the lens areas are composed of a plurality of fan-shaped areas, and the fan-shaped areas are located perpendicular to the main beam axis, and the apex of the fan-shaped area coincides with the intersection of the main optical axis and the lens section; the multiple fan-shaped areas are composed of multiple annular lens areas with different focal lengths. like Figure 7The lens O in is roughly divided into two fan-shaped areas, that is, the first fan-shaped area composed of lens areas 5 and 7, and the second fan-shaped area composed of lens areas 6 and 8, and each fan-shaped area contains two The main optical axes of the four lens areas 5-8 coincide, the centers of the lens areas 5-8 coincide with the vertices of the fan-shaped area, and have different focal lengths. Under the irradiation of a laser emitter, the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com