Strong gasflow sealing assembly based on lightning protection and arc extinguishing

A technology of sealing components and strong airflow, applied in electrical components, spark gap parts, spark gaps, etc., can solve the problems of insufficient arc effect, leakage of jet airflow, damage to insulator strings and hardware, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

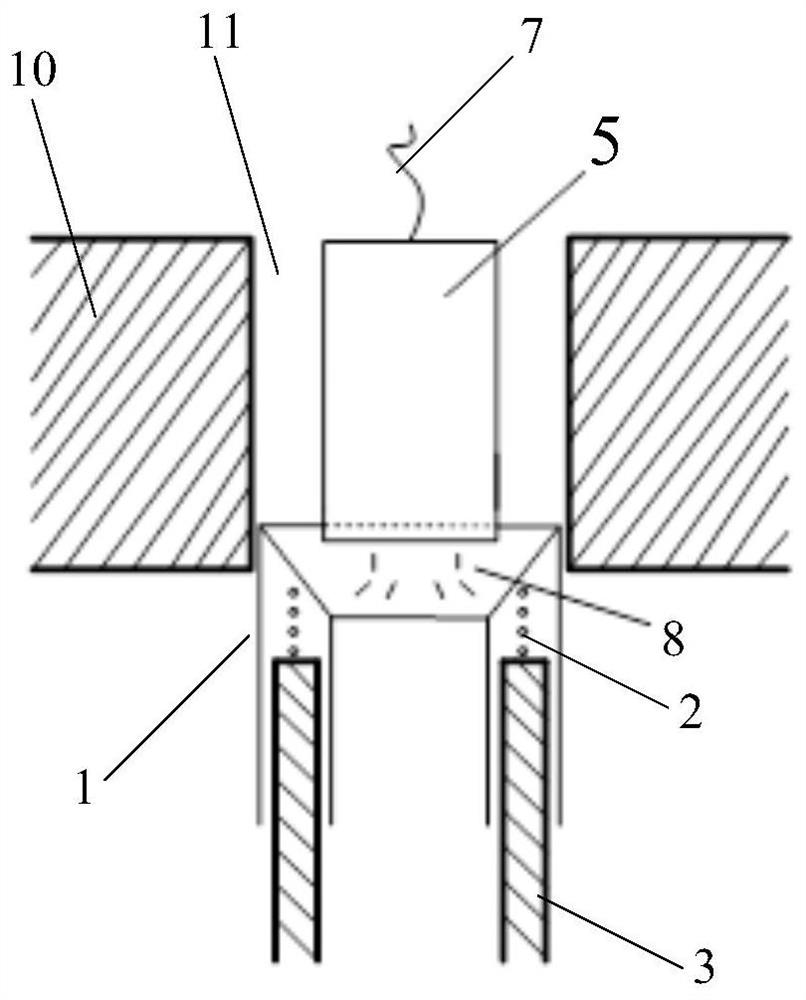

[0025] Example 1: Combining figure 2 As shown, a spring 2 is arranged on the top of the cylindrical cylinder 3, the upper end of the spring 2 is connected with the sealing sleeve 1, and the lower end of the spring 2 is connected with the top end of the cylindrical cylinder 3, so that the sealing Sleeve 1 can slide up and down relative to provide supporting force. Since the inner diameter of sealing sleeve 1 is slightly larger than cylindrical cylinder 3, it can be set on cylindrical cylinder 3, and under the action of spring 2, the sealing sleeve 1 can move up and down within a certain range. Since both the sealing sleeve 1 and the cylindrical cylinder 3 need to have a corresponding thickness as a support, the thickness is about 1-2 cm, and the material must be resistant to high temperature and high pressure, such as polyester fiber.

[0026] In the present invention, as image 3 As shown, the bottom end direction of the top end of the sealing sleeve 1 is a concave funnel s...

Embodiment 2

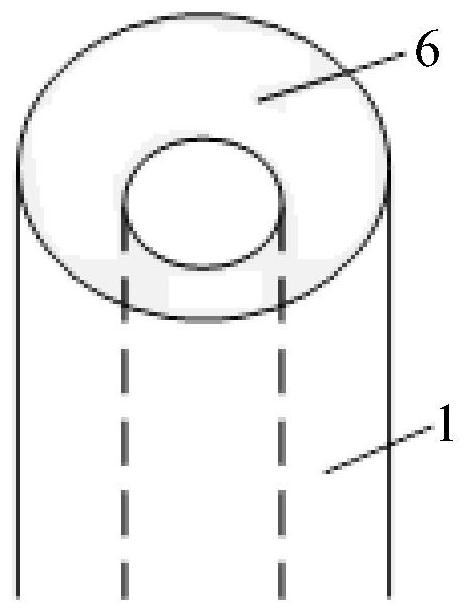

[0027] Embodiment 2: the difference between this embodiment and embodiment 1 is that, as Figure 4 with Figure 5As shown, the upper end of the spring 2 is internally connected with the top end of the sealing sleeve 1 , and the lower end of the spring 2 is connected with the top section of the cylindrical cylinder 3 . In the present invention, as Figure 4 , Figure 5 with Image 6 As shown, a spring hole 4 is provided on the top section of the cylinder 3, and the spring hole 4 extends vertically downward between the inner wall and the outer wall of the cylinder 3, and the middle and lower part of the spring 2 Set in the spring hole 4, the upper end of the spring 2 is internally connected with the top end of the sealing sleeve 1, and the number of spring holes 4 arranged on the top section of the cylindrical cylinder 3 is more than four, each The spring holes 4 are equidistantly distributed on the top section of the cylindrical cylinder 3, and a spring 2 is placed in each ...

Embodiment 3

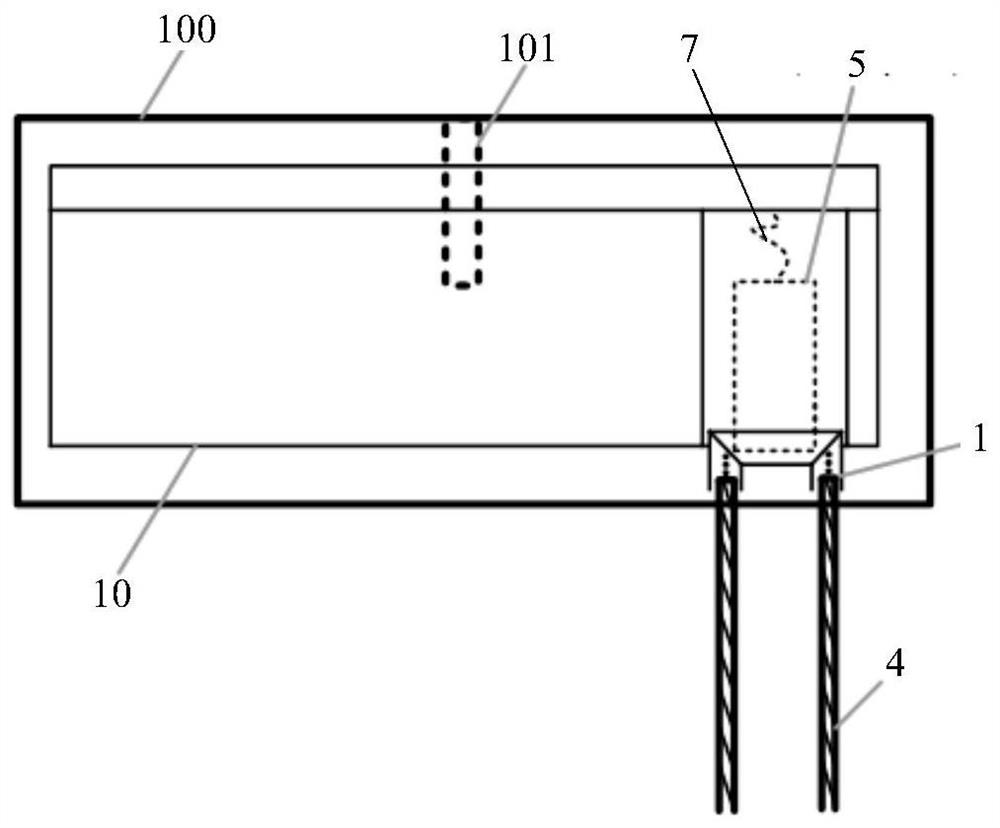

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 and Embodiment 2 is that, as Figure 7 with Figure 8 As shown, a shoulder 100 is cut transversely along the center of the sealing sleeve 1 at the outer wall of the middle or middle and lower portion of the sealing sleeve 1, and along the direction of the lower end of the sealing sleeve 1 And a neck 101 is cut between the inner edge of the shoulder 100 and the inner wall of the sealing sleeve 1, so that the sealing sleeve 1 is divided into upper and lower parts. The inner diameters of the upper and lower parts are the same, but the outer diameter of the upper part is The diameter is larger than the outer diameter of the lower part, and the lower part of the sealing sleeve 1 is a thin-walled hollow cylinder, whose outer diameter is slightly smaller than the inner diameter of the cylindrical cylinder, so that the sealing sleeve 1 can expand and contract up and down under the action of the spring 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com