Homemade chili sauce, chili sauce preparation method and stir-frying machine

A technology of chili sauce and stir-frying machine, which is applied in the field of seasoning products, can solve the problems of inability to satisfy consumers with different tastes, reduced nutritional value, single material of chili sauce, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

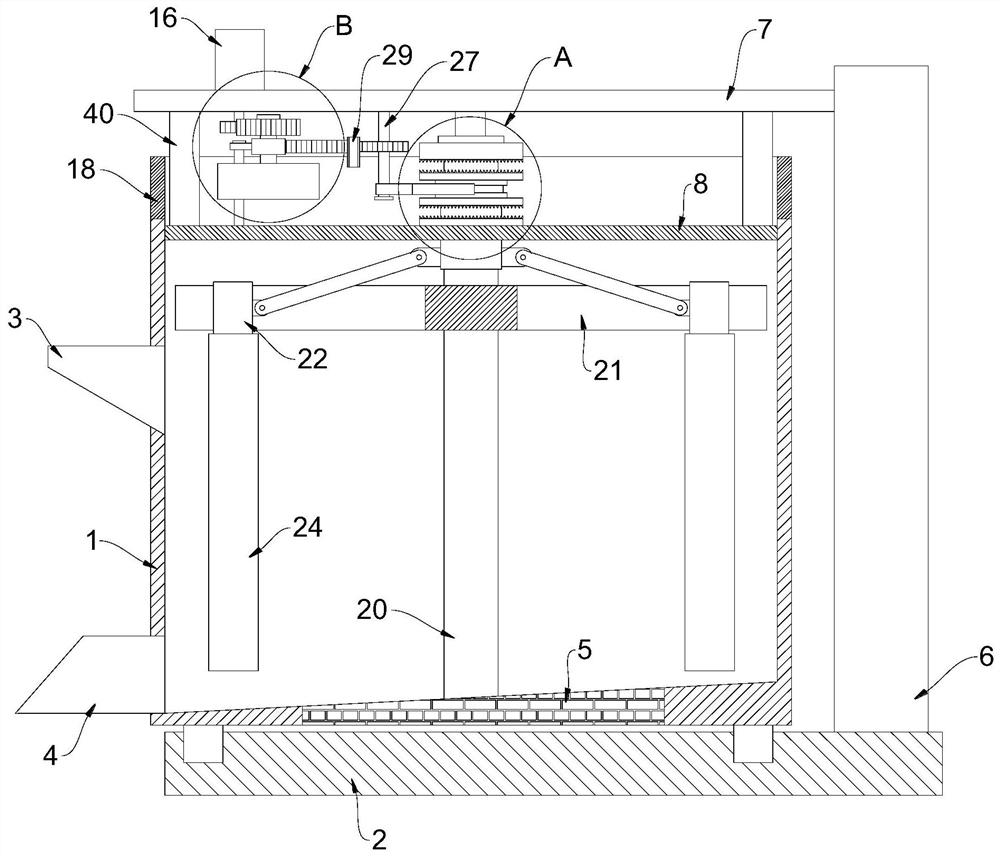

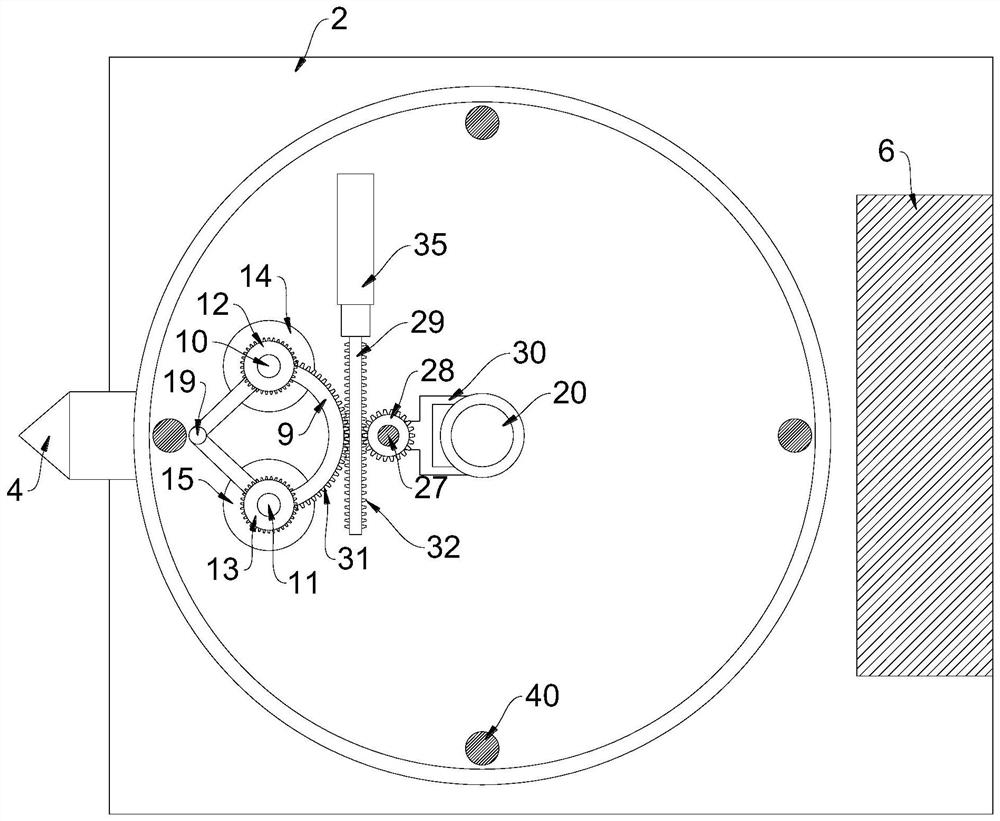

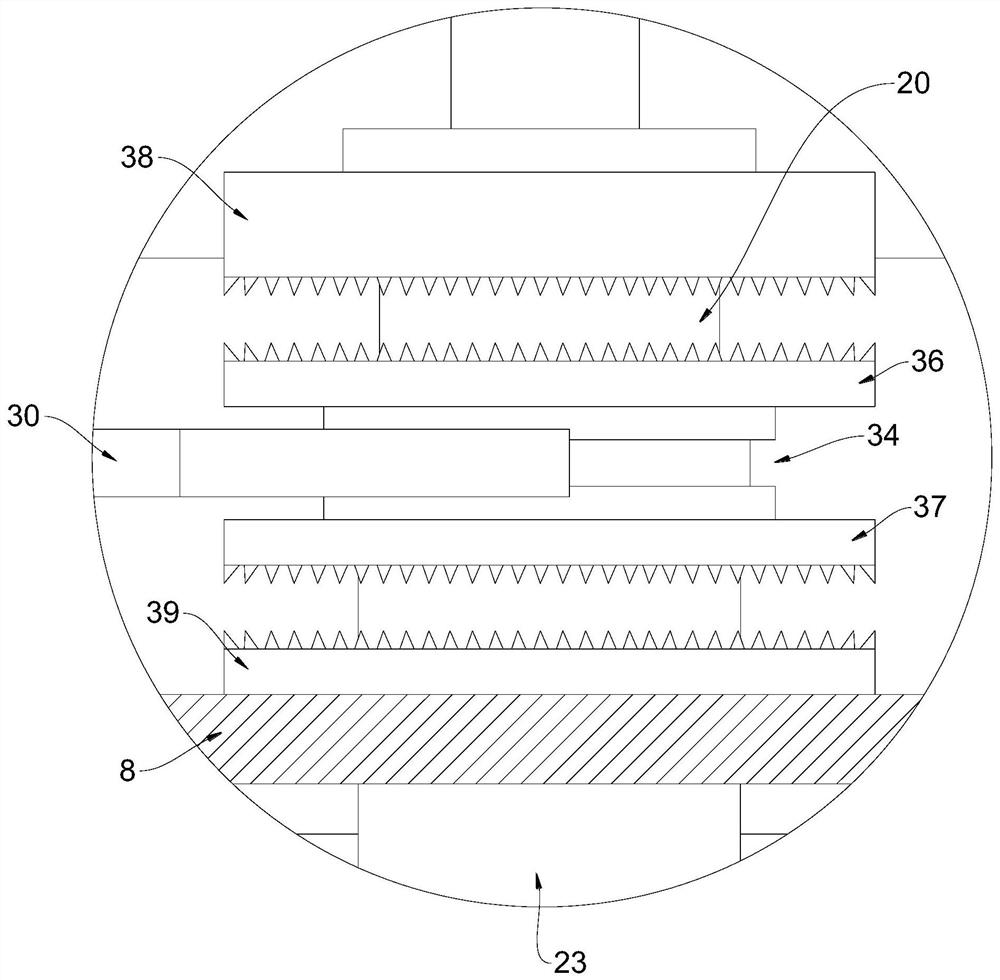

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment provides a kind of self-made chili sauce, and described chili sauce is made up of the raw material of following weight portion: 25 parts of onions, 100 parts of chopped green onions, 20 parts of coriander, 20 parts of garlic cloves, 100 parts of pepper noodles, 25 parts of Chinese prickly ash noodles, 20 parts of sweet noodle sauces 100 servings of light soy sauce, 25 servings of edible salt, 2 servings of thirteen spices, 25 servings of monosodium glutamate, 25 servings of chicken stock, 10 servings of defatted vegetables, 0.5 servings of dried soybeans, and an appropriate amount of cooking oil.

[0050] Further, the defatted vegetables include white radish and kohlrabi.

[0051] Present embodiment also provides a kind of chili sauce preparation method that is used to prepare above-mentioned self-made chili sauce, specifically adopts following steps:

[0052] 1) Pour 500ml of rapeseed oil into a fryer and heat it up, then add 25g of onion granule...

Embodiment 2

[0098]The difference between this embodiment and Example 1 is that in this embodiment: the chili sauce is made up of the following raw materials in parts by weight: 45 parts of onions, 150 parts of chopped green onions, 40 parts of coriander, 40 parts of garlic cloves, 120 parts of chili noodles, 35 parts of pepper noodles, 40 parts of sweet noodle sauce, 130 parts of soy sauce, 35 parts of edible salt, 6 parts of thirteen spices, 45 parts of monosodium glutamate, 45 parts of chicken essence, 20 parts of defatted vegetables, 1.5 parts of dried soybeans, and an appropriate amount of cooking oil.

Embodiment 3

[0100] The difference between this embodiment and Example 1 is that in this embodiment: the chili sauce is made up of the following raw materials in parts by weight: 30 parts of onions, 125 parts of chopped green onions, 30 parts of coriander, 30 parts of garlic cloves, 110 parts of chili noodles, 30 parts of pepper noodles, 30 parts of sweet noodle sauce, 115 parts of light soy sauce, 30 parts of edible salt, 4 parts of thirteen spices, 30 parts of monosodium glutamate, 30 parts of chicken essence, 15 parts of defatted vegetables, 15 parts of dried soybeans, and appropriate amount of cooking oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com