Surgical instrument for mounting acetabular cup

A technology for surgical instruments and acetabular cups, applied in the acetabular socket, hip joint, medical science and other directions, can solve the problems of reduced performance of surgical instruments, thread damage and deformation, shortened service life, etc., to reduce the possibility of deformation, The effect of increasing the contact surface and improving the cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

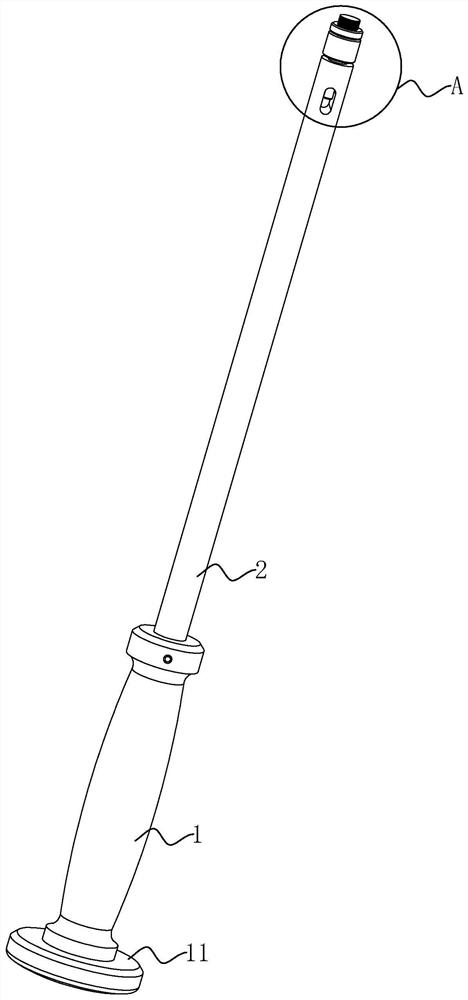

[0041] refer to figure 1 , the handle 1 is columnar, and its end away from the installer connecting rod 2 is fixedly connected with a bearing plate 11. The diameter of the bearing plate 11 is larger than that of the handle 1, and is mainly used to increase the force-bearing area so that the medical staff can hammer accurately.

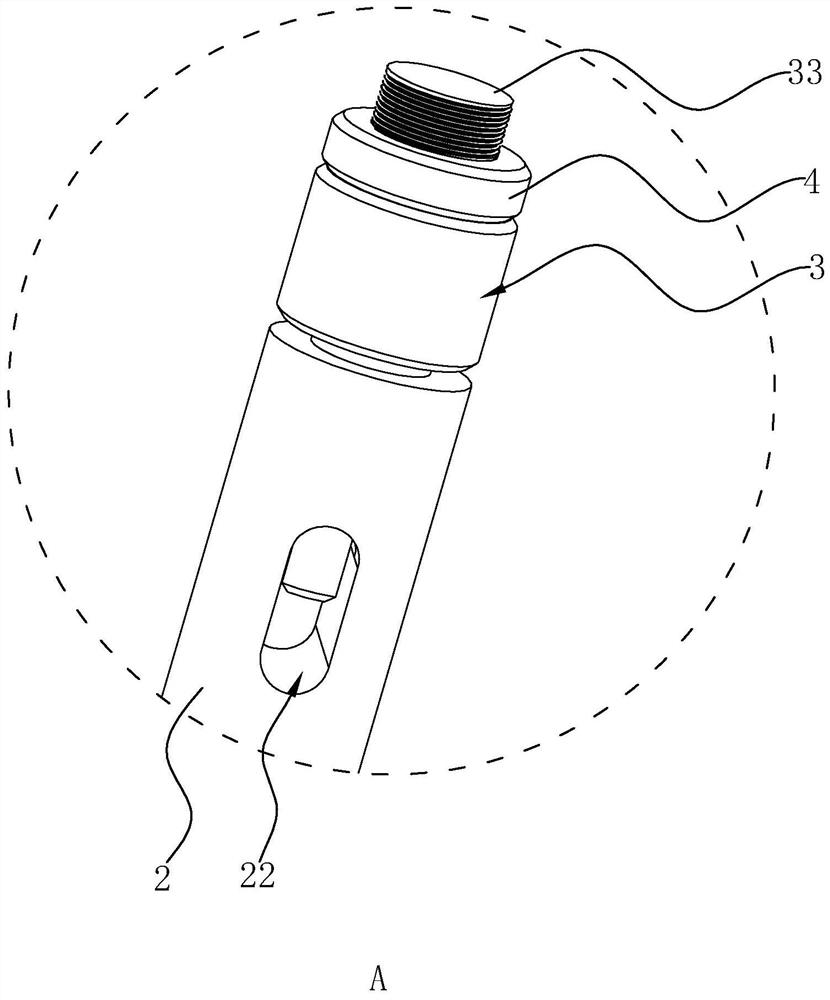

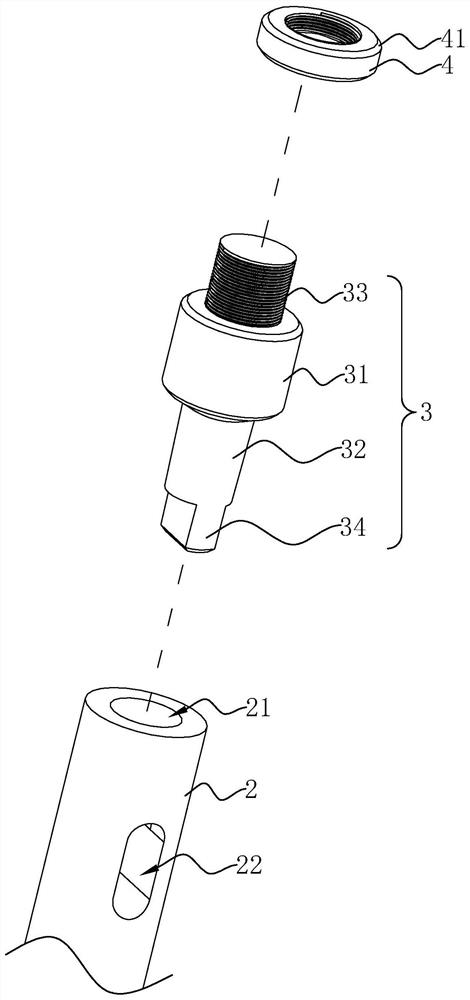

[0042] refer to figure 2 and image 3 , the screw joint 3 includes a cylinder 31, one end of the cylinder 31 is formed with an insertion rod 32, and the other end of the cylinder 31 is formed with a threaded rod 33; The screw joint 3 and the installer connecting rod 2 are fixed through the interference fit between the insertion rod 32 and the socket 21 . After the insertion rod 32 and the socket 21 are interference-fitted, there is an insertion gap between the cylinder 31 and the end of the installer connecting rod 2. The setting of the insertion gap enables medical personnel to insert into the insertion gap through tools. Inside, the spiral joint ...

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is that, referring to Figure 5 , the uniform force structure is a uniform force ring 6 with certain elasticity, one side of the uniform force ring 6 is fixedly connected with the buffer pad 4, and the uniform force ring 6 gradually moves from the side close to the buffer pad 4 to the side away from the buffer pad 4 Shrink inward, and form a closed structure with a curved surface on the side of the equalizing ring 6 away from the buffer pad 4. The closed structure can fit the inner wall of the acetabular cup through the curved surface. When the trend of displacement, the equalizing ring 6 presses against the acetabular cup, and evenly transmits the hammering force to the acetabular cup, which acts as a buffer and reduces the thread of the screw joint 3 and the pole hole of the acetabular cup Interaction forces between threads.

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is that, as Figure 6 As shown, the uniform force structure is a plurality of uniform force plates 7 centered on the threaded rod 33 and distributed around the circumference. The buffer pad 4 is fixed, and the other end is bent towards the threaded rod 33. This structural design enables the end of the equalizer 7 away from the buffer pad 4 to be better attached to the inner wall of the acetabular cup after the acetabular cup is installed. , evenly transmit the impact force, and at the same time, play a good buffering effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com