A high-efficiency pulverizer for energy-saving building construction garbage

A high-efficiency crushing and building construction technology, applied in the field of construction engineering, can solve the problems of unfavorable recycling, large production investment, poor powderization effect, etc., and achieve the effect of convenient classification and crushing, high crushing efficiency, and small production investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

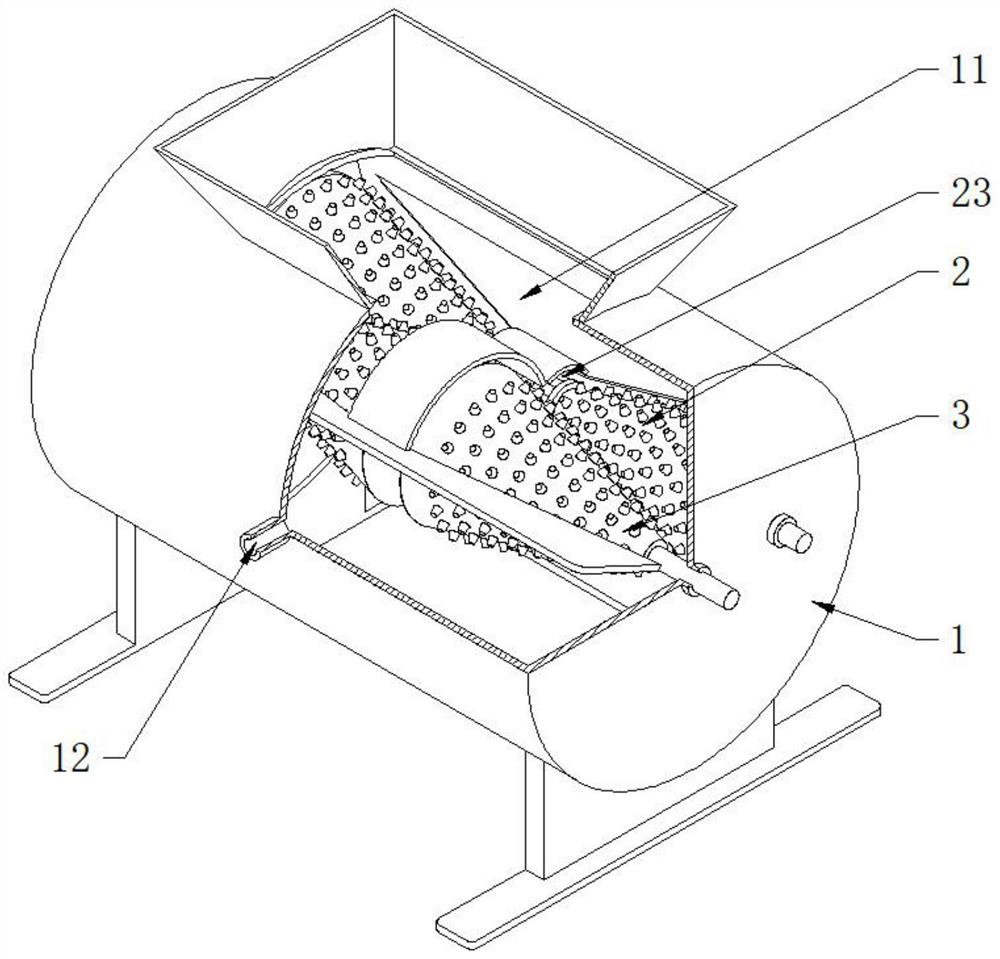

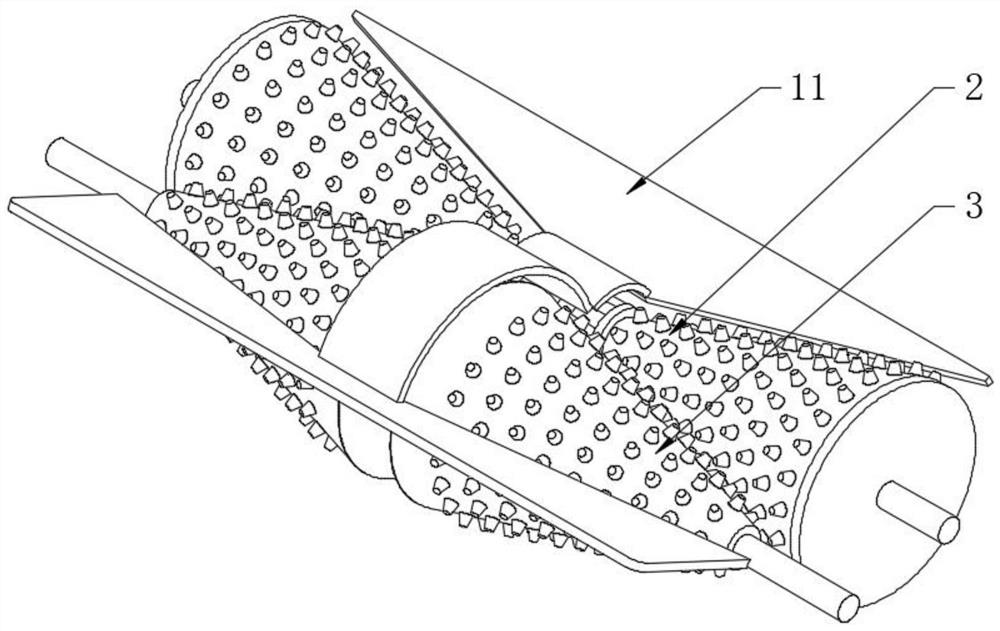

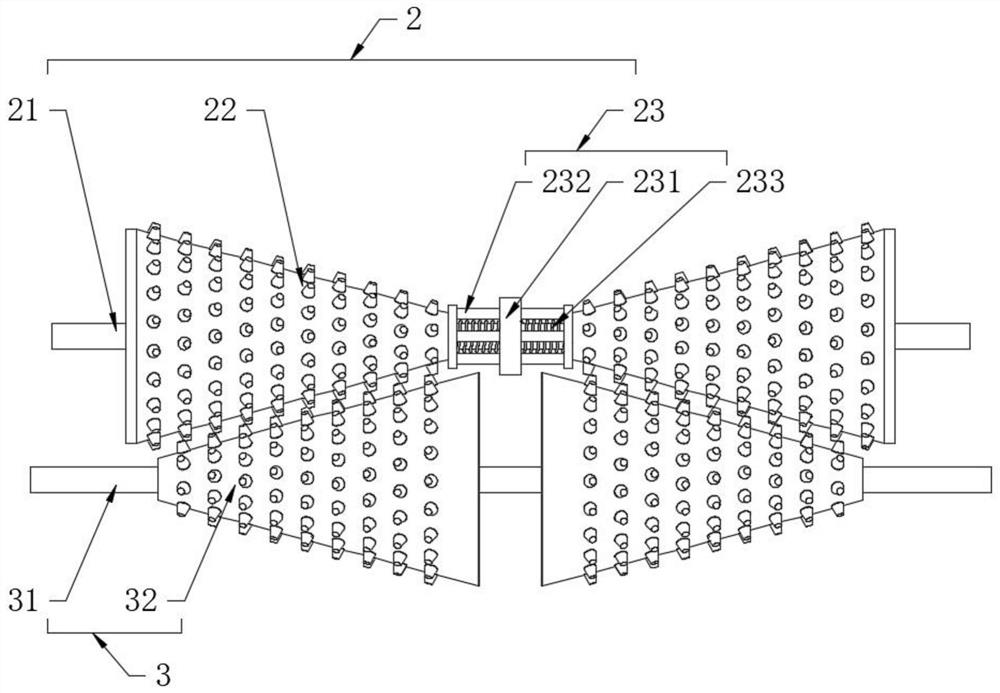

[0038] see Figure 1-3, an energy-saving building construction garbage high-efficiency crushing processor, comprising a crushing machine shell 1, a crushing roller 2 and a crushing roller 2 3, the crushing roller 1 2 and the crushing roller 2 3 are located in the crushing machine shell 1 and are in the shape of Parallel distribution and synchronous opposite rotation, the top of the pulverizer shell 1 is provided with a feeding guide cover for easy feeding, and the bottom is provided with a discharge port for discharging after pulverization; in this technical solution, the pulverizing roller 2 includes a supporting shaft 21 1. Pulverizing cylinder 1 22 and axial guide combination 23, the number of pulverizing cylinder 1 22 is two and is arranged coaxially on the supporting shaft 1 21, and the axial guiding combination 23 is fixedly sleeved on the supporting shaft 1 21 And between the two crushing cylinders 22, the two ends of the axial guide assembly 23 are fixedly connected wi...

Embodiment 2

[0040] see Figure 4 and Figure 5 The difference from Example 1 is that the bottom of the material guide plate 11 is connected with a crushing gap adjustment mechanism 4 located between the two crushing cylinders 32 and rotatingly matched with the support shaft 2 31 through the suspension plate 111. The crushing gap adjustment mechanism 4 It is used to adjust the distance between the two crushing cylinders 32, and then the size of the crushing gap mentioned in Embodiment 1 can be adjusted to facilitate classification and crushing; specifically, the crushing cylinder two 32 and the supporting shaft two 31 are axially sliding Fitting, the way of axial sliding fit also adopts the ball-assisted structure. The outer wall of the pulverizer shell 1 is fixedly provided with a guide sleeve 12 that is compatible with the pulverization gap adjustment mechanism 4. When it is necessary to control the action of the pulverization gap adjustment mechanism 4, use The rod-shaped tool can be i...

Embodiment 3

[0042] see Figure 6 and Figure 7 The difference from Embodiment 1 is that it also includes an arc plate 6 located inside the pulverizer shell 1 and a drive mechanism 7 located outside the pulverizer shell 1. The inner surface wall of the arc plate 6 passes through two rotating arms 61 and a support shaft. Two 31 rotating connections, the inner surface wall of the circular arc plate 6 is fixedly provided with a limit bar 62 with a triangular cross section near one end, and the inner surface wall of the circular arc plate 6 is provided with a uniform wall on one side of the limit bar 62 Distributed material leakage holes 63, through the construction waste crushed in embodiment 1, there is a phenomenon of unbalanced size and volume, that is to say, the pulverization effect is poor, so the crushing machine shell 1 can be made into a horizontal cylindrical shape and supported Shaft 2 31 is coaxially distributed, and the outer diameter of the circular arc plate 6 is smaller than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com