Compound bone crusher used for spine surgery

A surgical operation and bone crushing technology, which is applied in the field of medical devices, can solve problems such as inconsistent particle size, many spikes, and affecting the effect of bone crushing particles filling and supporting, and achieve the effect of improving structural strength and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

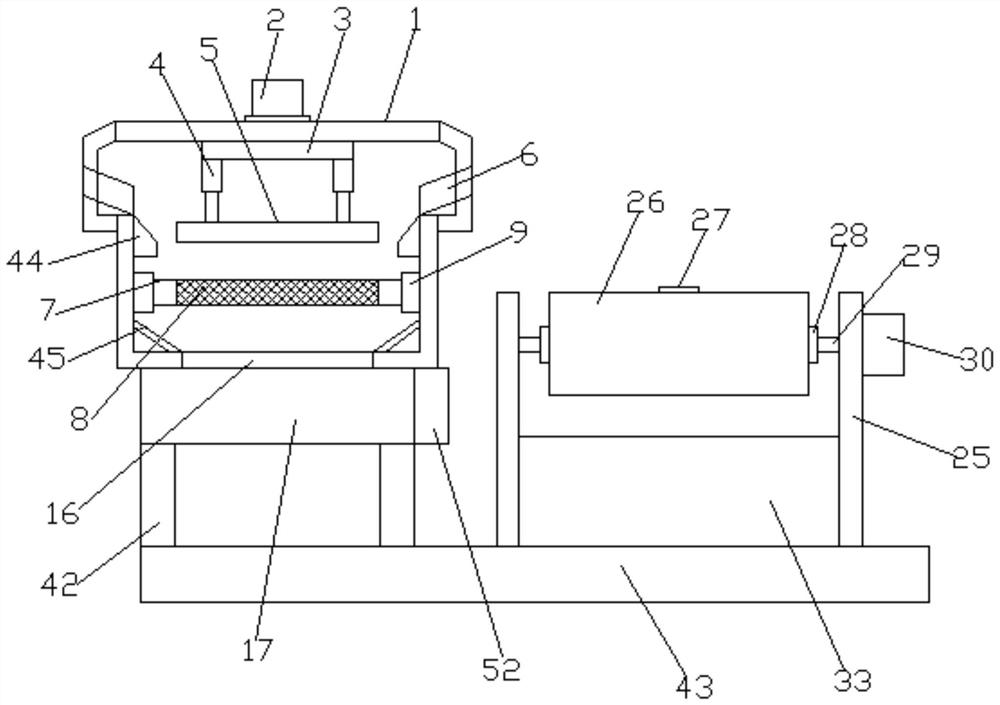

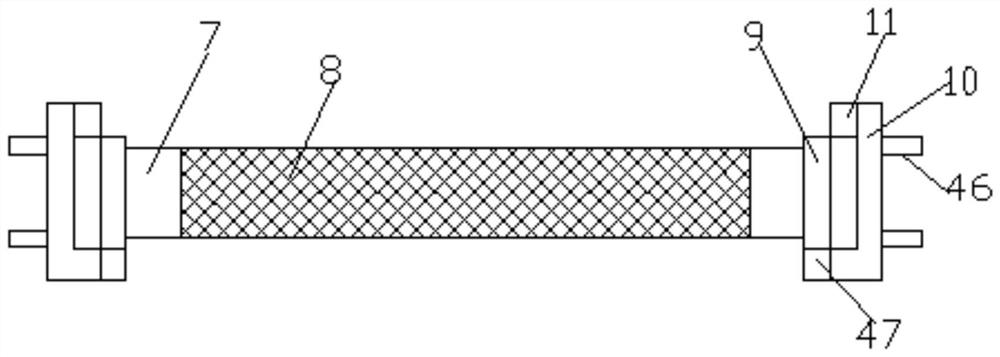

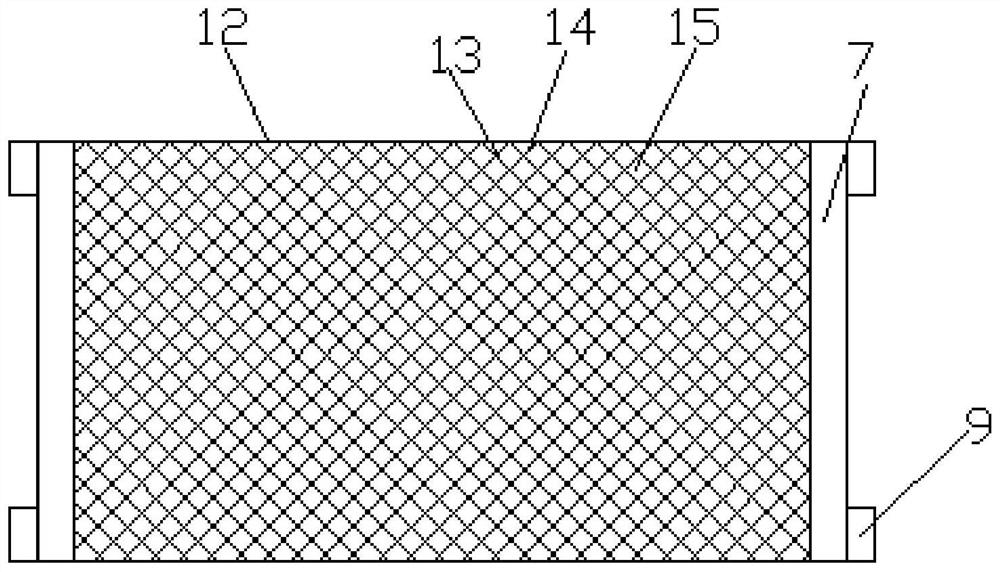

[0036] see Figure 1-7 , according to an embodiment of the present invention, a composite bone crushing device for spinal surgery includes a bone crushing box 1, a hydraulic cylinder 2 is arranged on the bone crushing box 1, and the inner top of the bone crushing box 1 is fixed with a The mounting plate 3 is symmetrically provided with a hydraulic telescopic rod 4 connected to the hydraulic cylinder 2, and a bone crushing plate 5 is connected between the bottom ends of the hydraulic telescopic rod 4, and the bone crushing box 1 Feed pipes 6 are provided on both sides of the crushing plate 5, a crushing plate 7 is provided below the crushing plate 5, a crushing structure net 8 is provided on the crushing plate 7, and a disassembly structure 54 is provided on both sides of the crushing plate 7 , both sides of the crushing plate 7 are provided with clamping blocks 9, and both sides of the inner wall of the bone crushing box 1 are fixedly provided with connecting blocks 10, and th...

Embodiment 2

[0039] Such as figure 1 As shown, the lower side of the housing 18 is symmetrically provided with supporting legs 42, and a fixed bottom plate 43 is connected between the bottom of the supporting legs 42 and the fixed side plate 25. Using the functions of the supporting legs 42 and the fixed bottom plate 43, the equipment overall support.

Embodiment 3

[0041] Such as figure 1 As shown, the inner wall of the bone crushing box 1 is located below the feed pipe 6 and is provided with a material guide plate 44. The material guide plate 44 is provided with a material guide groove, and the bone is guided by the material guide plate 44. The added bone acts as a guide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com