Peanut tail picking and sorting machine

A sorting machine, peanut technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of high impurity content, poor tailing effect, low degree of automation, etc., to achieve good tailing effect and easy tailing The effect, the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: This embodiment aims to provide a kind of peanut picking and selecting machine, which is mainly used in the initial processing of peanuts to remove the tail roots of peanuts. For the poor tail removal effect in existing machinery, it is still necessary to Manually process again, and the impurity rate after picking the tail is high, and it is troublesome to use. For this reason, this embodiment provides a peanut picking and selecting machine that integrates picking, winnowing, and screening. Peanut pods detached from peanut seedlings are tail-picked.

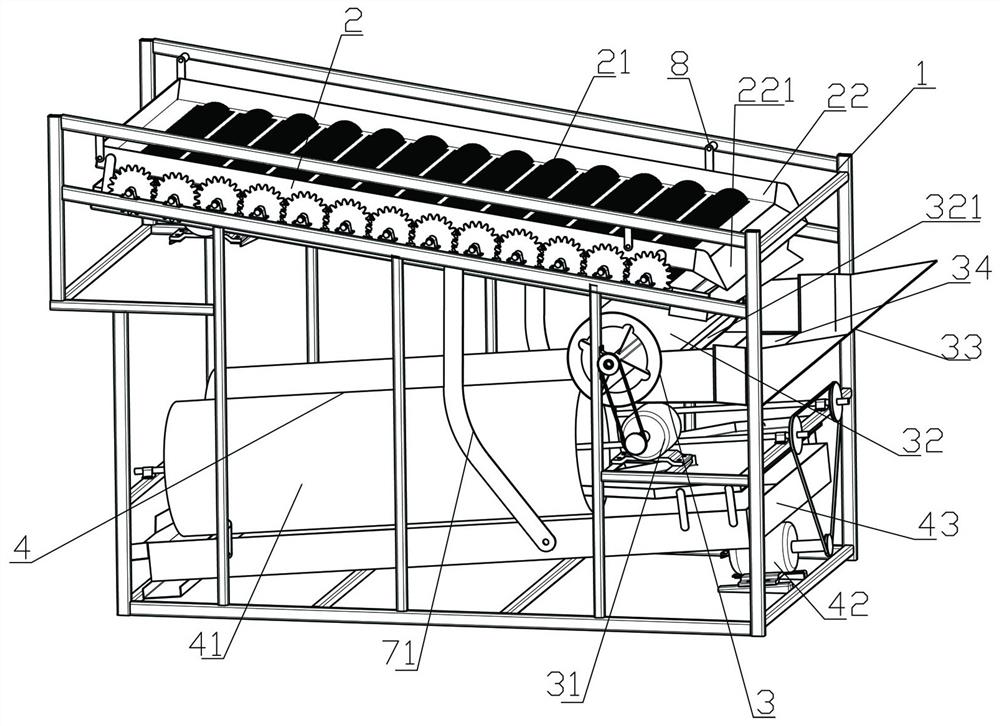

[0036] Specifically as figure 1 , Figure 6 and Figure 7 As shown, the tail picking and selecting machine includes a frame 1, a tail picking mechanism 2, a wind selection mechanism 3 and a screening mechanism 4; fixation.

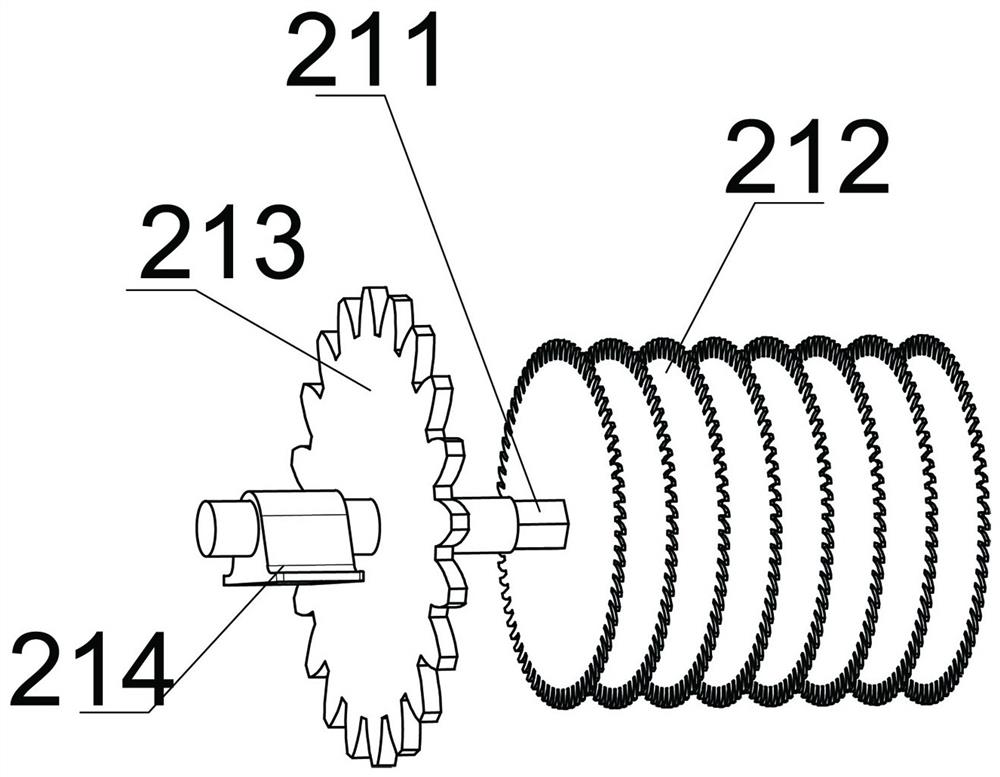

[0037] The tail removal mechanism 2 includes a first reduction motor 24, a tail removal screen 22, a tail removal saw blade group and a tail root collecting tank 23; saw blade group ...

Embodiment 2

[0045] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further limits the number of screen drums.

[0046] Two screen drums 41 are arranged side by side, and the outer ends of the stirring shafts of the two screen drums are respectively provided with driven wheels 46. The driven wheels 46 are connected with the driving wheel of the screening motor 42 through a belt drive, and the middle part of the material guide plate A material distribution plate is provided.

[0047] like Figure 5 As shown, the ends of the two stirring shafts are respectively provided with a first driven wheel and a second driven wheel, and the two driven wheels are located on the outside of the impurity collection tank and are connected to the driving wheel in transmission, and the first driven wheel and the second driven wheel are located at The two bottom corners of the isosceles triangle, and the driving wheel is located at the top corner of ...

Embodiment 3

[0050] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further limits the structure of the tail picking mechanism 2 .

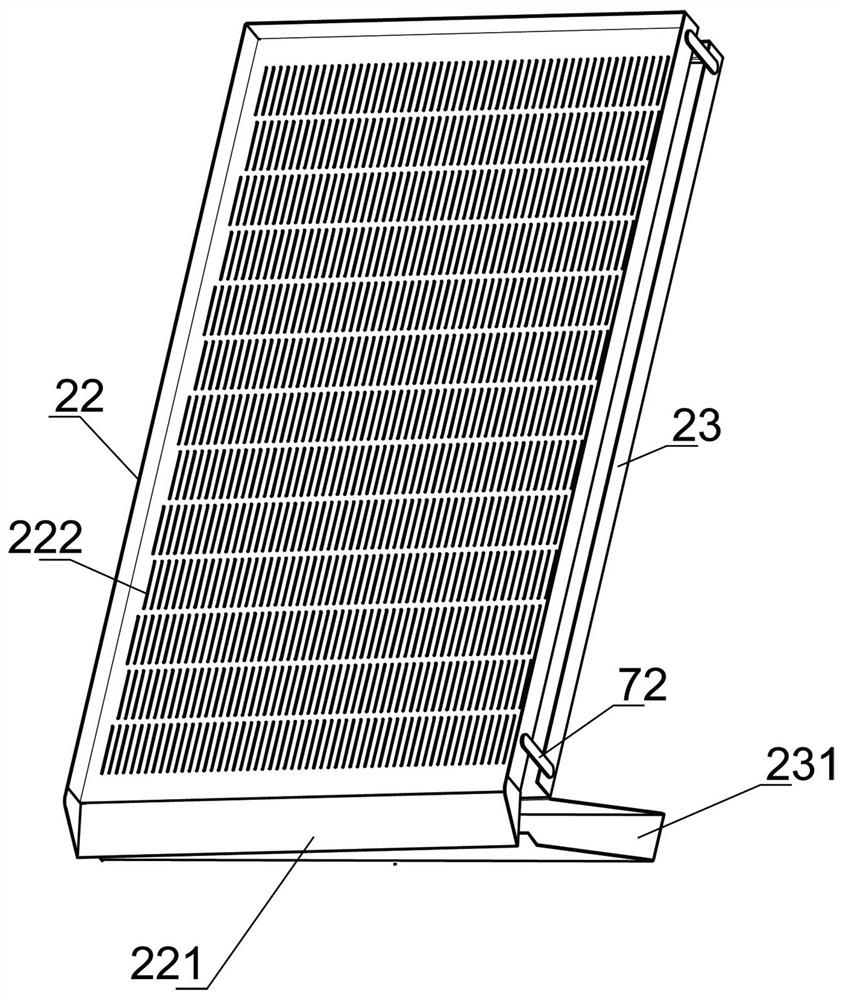

[0051] like Figure 8-10 As shown, two adjacent rows of sieve long holes 222 are staggered, and the upper row of sieve long holes is aimed at the middle part of the lower row of sieve long holes;

[0052] The frame 1 is provided with a fixed cross brace 92, the fixed cross brace 92 is provided with an adjustment rod 91, and an adjustment hole 9 is provided between two adjacent rows of long holes of the screen, and the adjustment rod 91 Under the vibration of the tail screen cloth, the interval stretches out or retracts into the adjustment hole 92 .

[0053] Because in the process of picking the tail, the tail roots of the horizontal peanut pods are perpendicular to the saw blade and are easy to be removed, but the vertical peanut pods in the same direction as the saw blade should not be removed. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com