A gear cleaning device for machining

A technology of machining and cleaning device, applied in the field of machining, can solve the problems of lack of direct brushing of gears, poor cleaning effect, etc., and achieve the effects of convenient access, improved anti-skid performance, and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

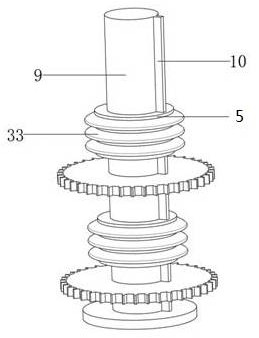

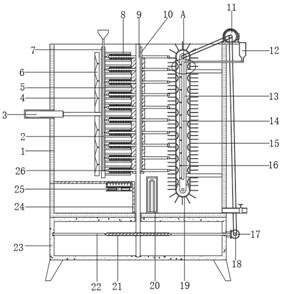

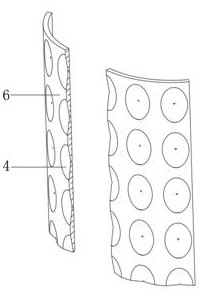

[0030] refer to Figure 1-4 , a gear cleaning device for machining, including a cleaning cylinder 1, the bottom outer wall of the cleaning cylinder 1 is fixed with a transmission bottom case 23 by bolts, and the transmission bottom case 23 and the cleaning cylinder 1 are rotatably connected with the same rotating column 9 through a bearing, and the rotating One side of the circumferential outer wall of the column 9 is welded with a convex key 10, and the outer wall of the rotating column 9 is staggered with gears and a spacer 5 in turn, and a first-order cleaning mechanism and a second-order cleaning mechanism are respectively installed on both sides of the cleaning drum 1, and the first-order cleaning mechanism. The cleaning mechanism includes a mounting frame 13 fixed on one side of the inner wall of the cleaning cylinder 1 by bolts. Both ends of the mounting frame 13 are connected with round rollers through bearings, and the outer walls of the two round rollers are sleeved w...

Embodiment 2

[0041] refer to Figure 5 , a gear cleaning device for machining. Compared with Embodiment 1, this embodiment also includes that the circumferential outer wall of the spacer 5 is welded with equidistantly distributed oblique convex rings 33, and the angle between the inclined convex ring 33 and the spacer 5 is welded. is an acute angle.

[0042] When the present invention is used, the oblique convex ring 33 is arranged on the circumferential outer wall of the spacer 5 to effectively improve the anti-skid performance of the spacer 5, thereby achieving the purpose of facilitating the taking and placing of the spacer 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com