Descaling agent and cleaning system for descaling boiler by using same

A cleaning system and descaling agent technology, applied in boiler cleaning devices, detergent compounding agents, detergent compositions, etc., can solve the problem of poor cleaning effect of sulfate scale and silicon oxide, short cleaning time, long cleaning time, etc. problem, to achieve the effects of obvious descaling effect, weak acid safety, and short cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

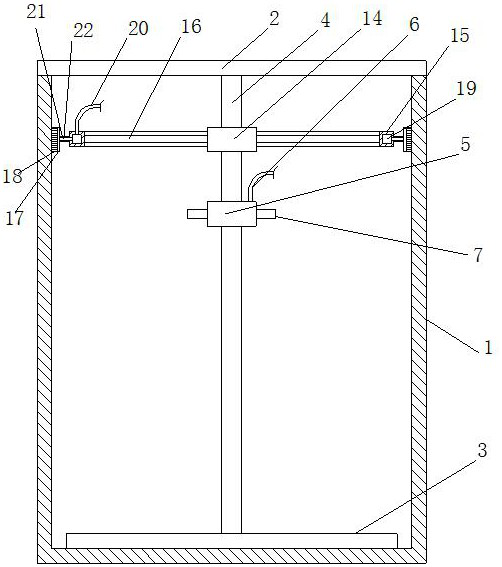

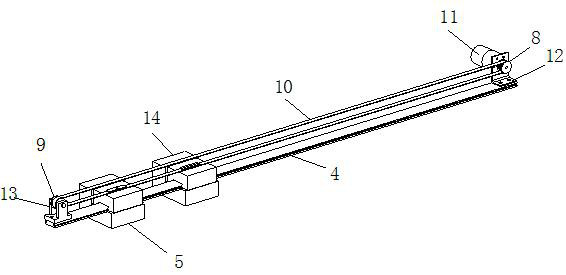

Image

Examples

Embodiment 1

[0026]A descaling agent used in a cleaning system that uses a descaling agent to descale boilers. The raw materials include: 20% glycolic acid, 15% hydroxyethylidene diphosphate, and 1.3% disodium hydroxyethylidene diphosphate. %, DL malic acid 15%, malic acid 13%, surfactant 0.1%, molybdate 3.5%, and the rest is deionized water.

Embodiment 2

[0028] A descaling agent used in a cleaning system that uses a descaling agent to descale boilers. The raw materials include: 18% glycolic acid, 20% hydroxyethylidene diphosphoric acid, 2.6% disodium hydroxyethylidene diphosphate %, DL malic acid 10%, malic acid 19%, surfactant 0.3%, molybdate 5%, and the rest is deionized water.

Embodiment 3

[0030] A descaling agent used in a cleaning system that uses a descaling agent to descale boilers. The raw materials include: 26% glycolic acid, 10% hydroxyethylidene diphosphate, and 0.8% disodium hydroxyethylidene diphosphate. %, DL malic acid 20%, malic acid 10%, surfactant 0.1%, molybdate 2%, and the rest is deionized water.

[0031] The descaling agent proposed by the present invention thoroughly cleans scales such as carbonates, sulfates, silicates and their mixed scales under normal temperature conditions. After the system is cleaned, it has obvious corrosion and resistance effects. It is a kind of carbon steel and stainless steel system equipment, the cleaning effect is less affected by temperature, its weak acidity is safe, non-toxic and environmentally friendly, the cleaning time is short, and it can be completely biodegraded. descaler.

[0032] The descaling power of descaling agent in embodiment 1-3 is shown in the table below:

[0033] Example Descal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com