High-pressure jet type mechanical CIP cleaning and disinfecting system for emulsifying equipment

A high-pressure spraying, cleaning and disinfection technology, which is applied in the direction of disinfection, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems that the effect of cleaning and disinfection cannot be guaranteed, the material body cannot be cleaned thoroughly, and cannot be cleaned thoroughly. To achieve the effect of avoiding chemical cleaning agent/disinfectant residue, avoiding cleaning dead ends, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

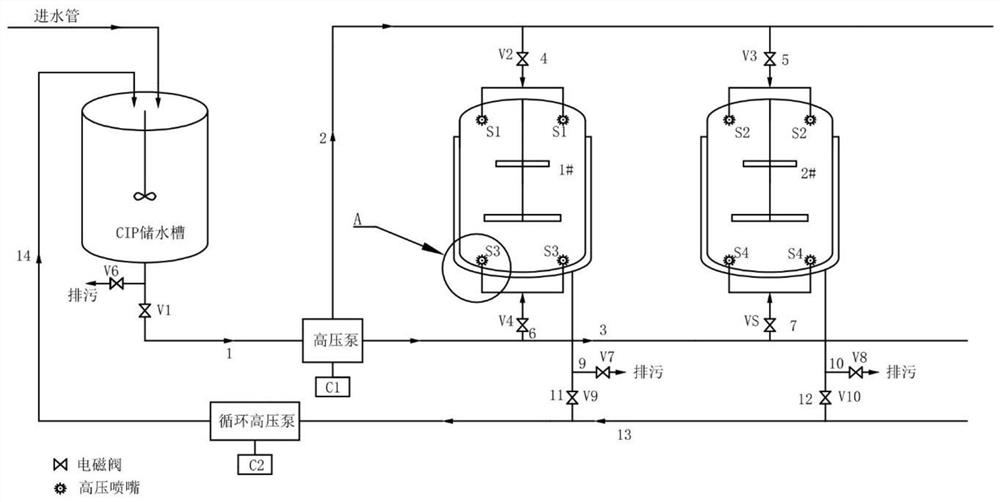

[0039] Such as figure 1 As shown, a high-pressure jet mechanical CIP cleaning and disinfection system includes a CIP water storage tank for storing CIP cleaning and disinfection water. At the same time, the water storage tank can be heated so that the temperature of the CIP cleaning water can reach 90-95 °C; figure 1Among them, CIP is CIP water storage tank; P1 is high-pressure injection pump; S1, S2, S3, S4 are high-pressure injection parts; 1#, 2# are vacuum homogeneous emulsification pots; P2 is high-pressure circulation pump; 1 is CIP process water delivery Pipeline; 2, 3 are high-pressure injection main pipes; 4, 5, 6, 7 are high-pressure injection branch pipes; 8, 9, 10 are sewage pipes; 11, 12 are circulating water branch pipes; 13, 14 are circulating water main pipes ; V1 is process water delivery valve; V2, V3, V4, V5 are high-pressure injection valves; V6, V7, V8 are sewage valves; V9, V10 are cycle cleaning valves; C1, C2 are control panels.

[0040] Conveyor pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com