Modular underground water permeable reaction pile and implementation method thereof

A groundwater and modular technology, applied in the restoration of sheet pile walls, buildings, and contaminated soil, etc., can solve the problems of complex geological conditions that cannot be repaired, and achieve the effects of corrosion resistance, environmental pollution prevention, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

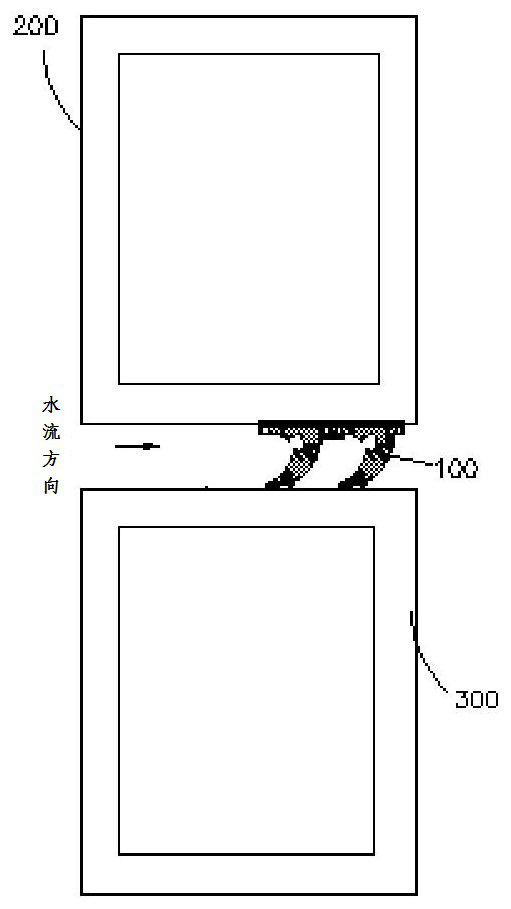

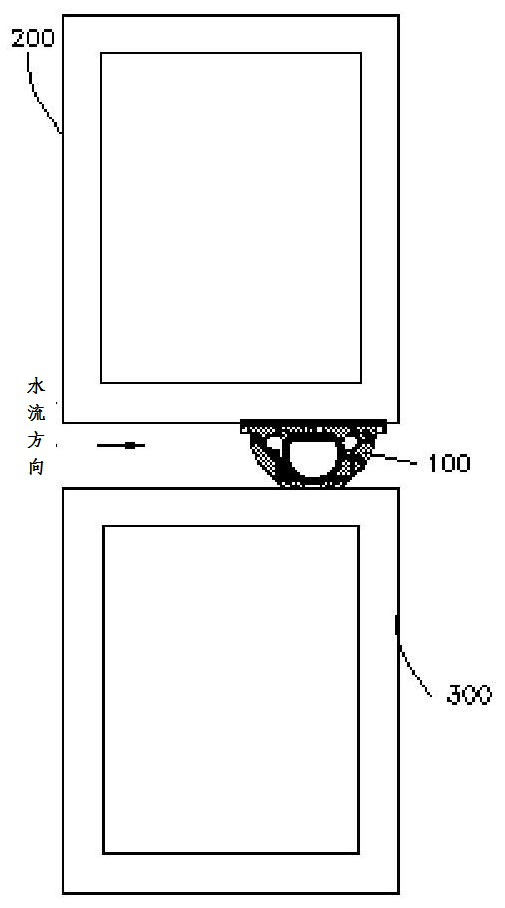

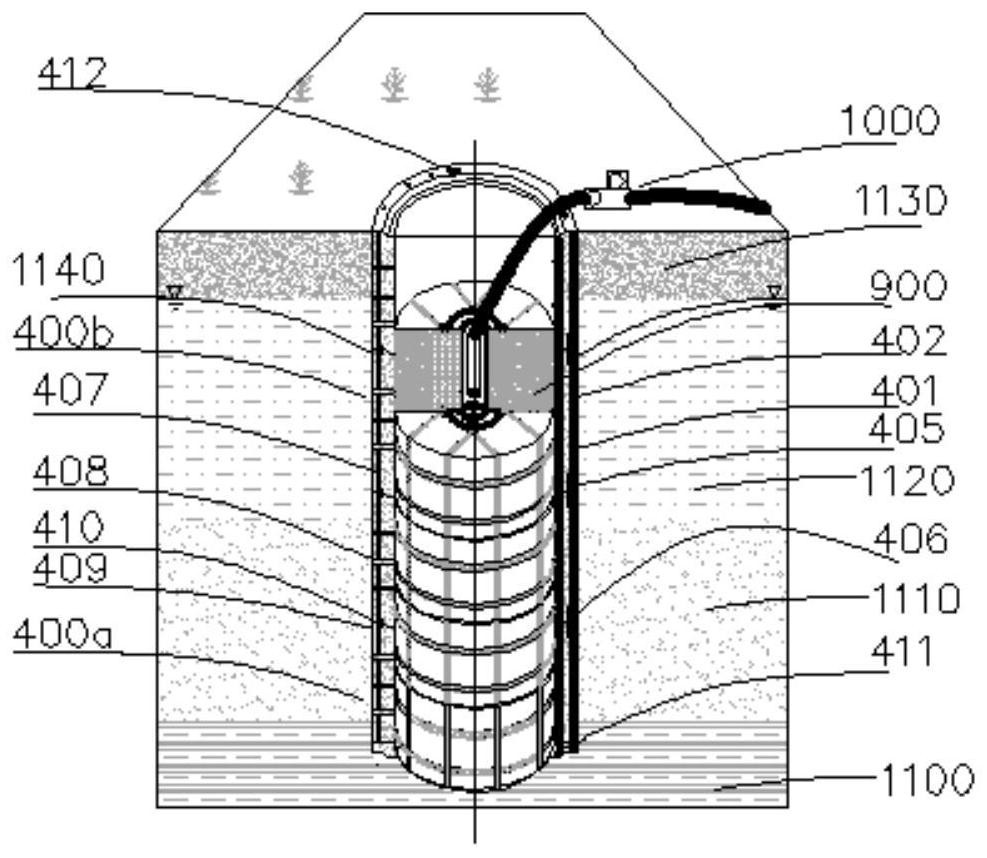

[0060] The modular groundwater permeable reaction pile of the present invention adopts a modular design. Firstly, it is necessary to construct a frame structure for loading the osmotic reaction box module underground, adopt a specific polymer mud retaining wall, and vertically excavate with a rotary drilling rig. Circular steel pipe or concrete prefabricated cylinder, the frame structure can support the surrounding soil, and does not block the seepage channel of the groundwater flow, and the circular reaction medium module ton bag or box unit is loaded in the outer frame of the above reaction pile, Then create a hydraulic gradient through a specific water pump to realize groundwater flow or circulation, realize contaminated groundwater passing through the pores of the reaction medium, and repair and control the pollutants in it, so as to realize the restoration of specific complex formation conditions or local areas in deeper parts Governance, which can be used alone or as a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com