Current monitoring system based on high-precision copper pipe drawing high-speed motor

A high-speed motor and current monitoring technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as unqualified products and not being discovered by operators in time, achieve high leak detection rate, avoid batch scrapping, and save energy The effect of human cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

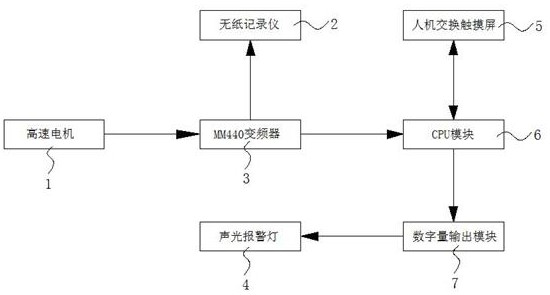

[0023] Such as figure 1 As shown, a current monitoring system based on a high-precision copper pipe drawing high-speed motor of the present invention includes a PLC programmable control mechanism applied to a copper pipe production line and a core data monitoring system located in the middle of the production line. The PLC programmable The control mechanism is based on the CPU module 6 as the control core, and the digital output module 7 is used in combination at the same time; the CPU module 6 is connected to the digital output module 7 through a U-shaped backplane; the core data monitoring system includes a high-speed motor 1, MM440 Inverter 3 and human-machine exchange touch screen 5; the offline of the MM440 inverter 3 is connected to the high-speed motor 1, and at the same time it is connected to the CPU module 6 through profibus two-way c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com