Machining locating device and steel tube bamboo joint simulated machining process

A technology of positioning device and mounting frame, which is applied in the field of imitation bamboo joints of steel pipes, and can solve problems such as inconvenient operation, poor appearance, and poor practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

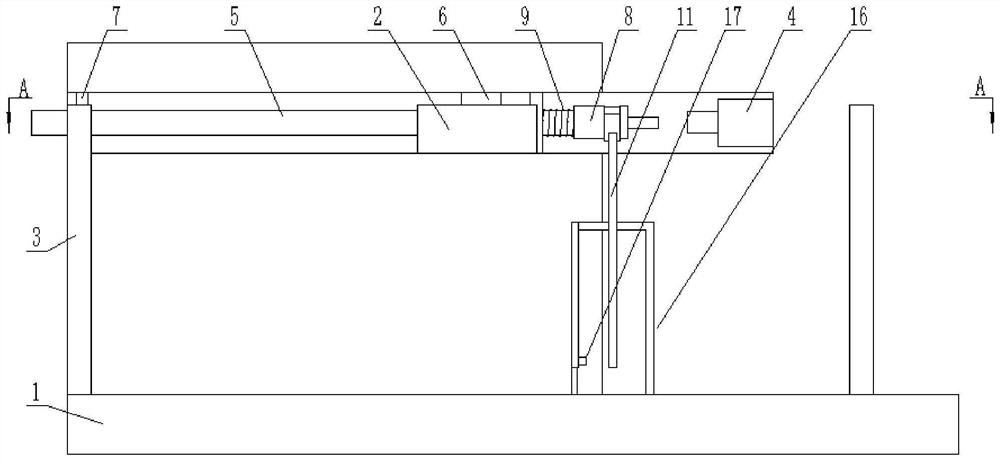

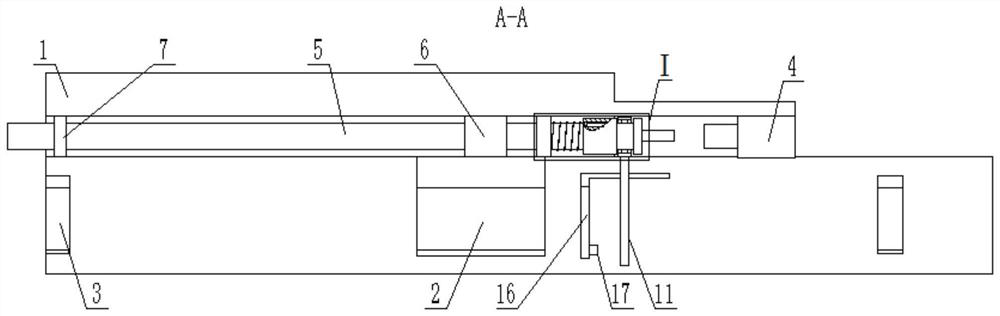

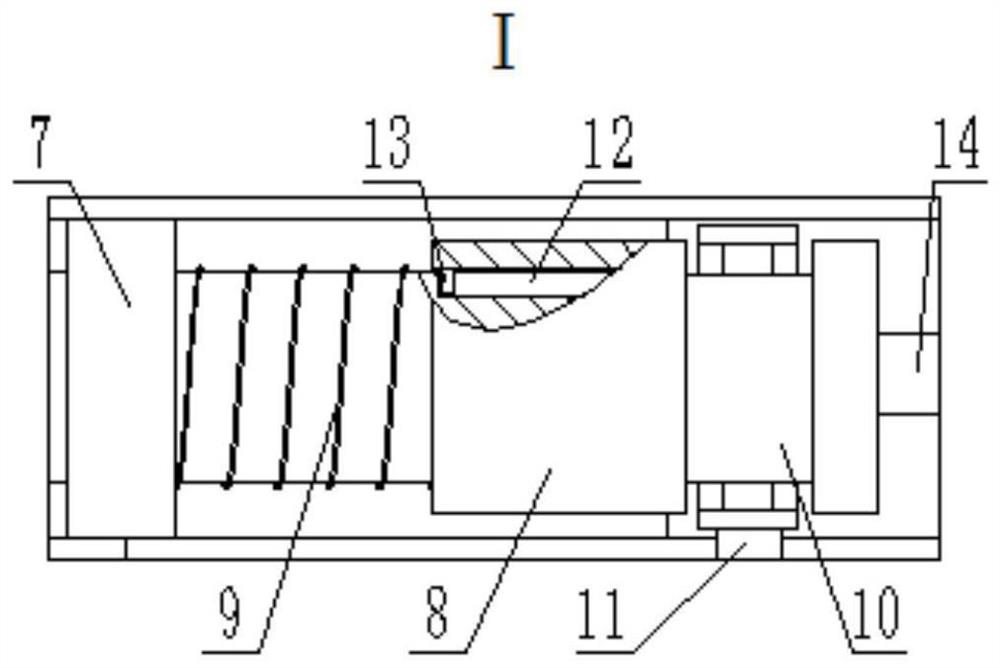

[0035] A processing positioning device, such as Figure 1-Figure 2 , Figure 5-Figure 6 As shown, it includes a support seat 3 with balls and a mounting frame 1, and the mounting frame 1 is provided with a carrying platform 2 and a driving mechanism for moving the carrying platform 2. The upper part of the support seat 3 and the upper part of the bearing platform 2 are both semicircular structures, which match the structure of the steel pipe and are easy to place; the inside of the support seat 3 is movable to install balls. When the steel pipe needs to be rotated, the balls can reduce the contact between the support seat 3 and the The friction force between the steel pipes facilitates the rotation of the steel pipes; the inner side of the carrying platform 2 is provided with a rubber layer, and the rubber layer is beneficial for the carrying platform 2 to move the steel pipes.

[0036] like Figure 1-Figure 2 As shown, the drive structure includes a motor 4, a lead screw 5 ...

Embodiment 2

[0045] On the basis of embodiment 1, a kind of steel pipe imitation bamboo joint processing technology comprises the following steps:

[0046] Step 1, select two steel wires with different diameters, cut the steel wires according to the diameter of the steel pipe, then apply the above-mentioned positioning device to fix the steel pipe, and seamlessly weld the cut two steel wires with different diameters to the steel pipe to form bamboo joints;

[0047] During the construction of steel pipe imitation bamboo technology, in order to achieve the shape and fidelity, repeated practice is required to ensure the perfect combination of shape and proportion of steel pipe imitation bamboo products. For example, when the steel pipe imitates bamboo, a φ19cm steel pipe and two iron wires of φ6.401mm and φ5.385mm are used, and the iron wire and the steel pipe are seamlessly welded to form a bamboo joint.

[0048] Step 2: Repeat step 1 to imitate the next bamboo node according to the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com