Floating type large plane polishing device for wood

A floating, large-plane technology, applied in the direction of grinding/polishing safety devices, grinding machines, abrasive belt grinding machines, etc., can solve the problems of rising surface temperature of grinding equipment and difficulty in controlling the degree of adhesion between grinding equipment and plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

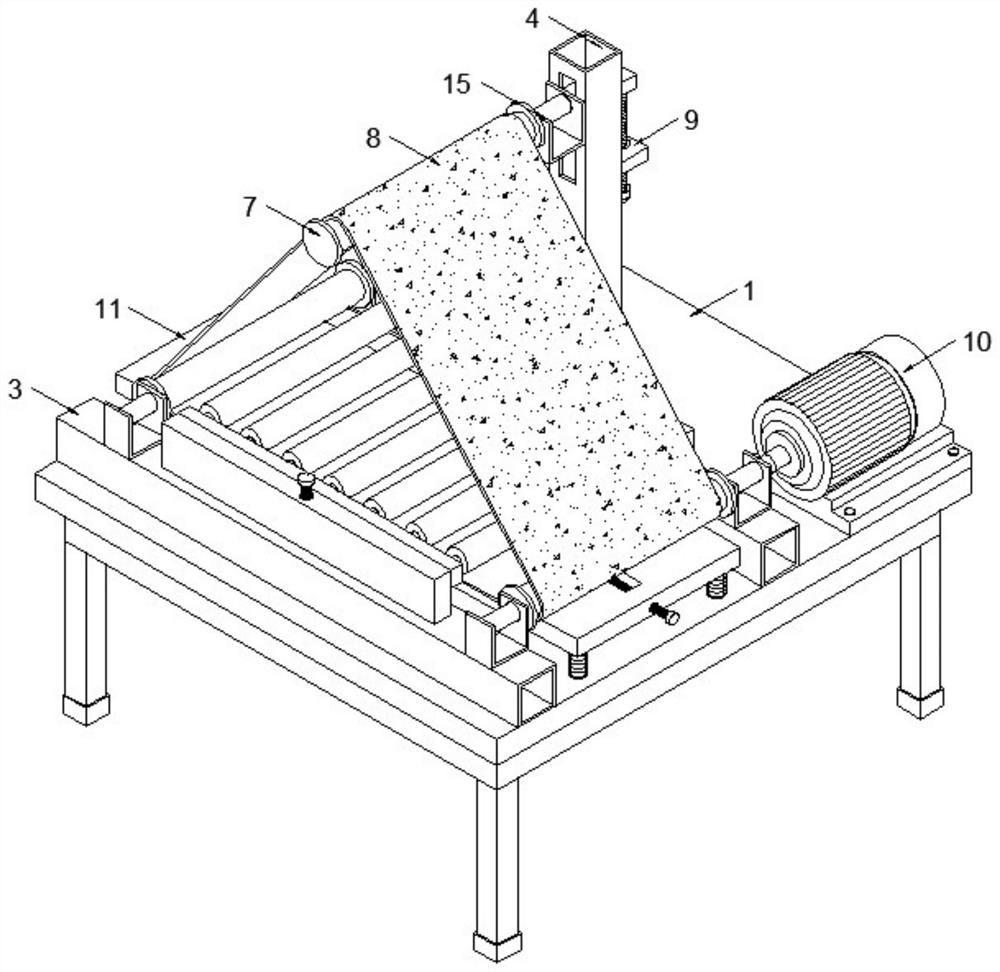

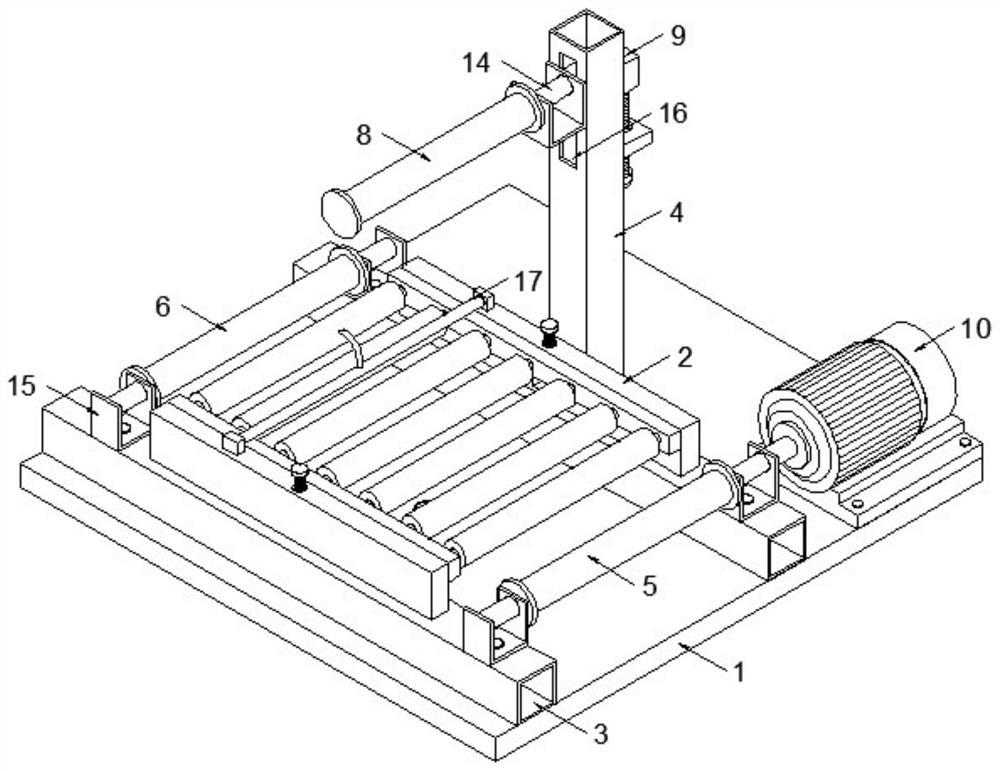

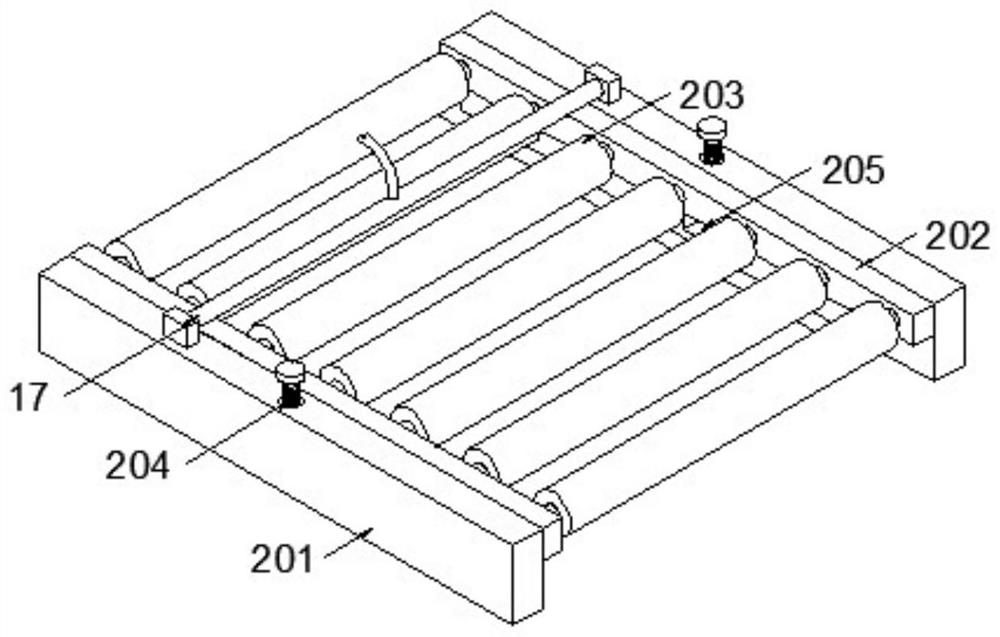

[0031] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6As shown, a floating large-plane grinding device for wood in the present invention includes a workbench 1, the two sides of the top of the workbench 1 are respectively fixed with fixed plates 3, and the workbench 1 is located in the middle of one side of the fixed plate 3 The base plate 4 is fixedly arranged, and the tops of the two fixed plates 3 on the same side are respectively provided with the same driving pulley 5 and the same driven pulley 6, and the tops of the two fixed plates 3 are located between the driving pulley 5 and the driven belt. A pressure roller assembly 2 is arranged between the wheels 6, and the pressure roller assembly 2 includes two connection seats 201, two movable plates 202 and several pressure rollers 203, and the two connection seats 201 are fixedly arranged on the tops of the two fixed plates 3 respectively. In the middle part, two movable plates 202...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com