Aircraft fuel tank inerting system and fuel tank explosion-proof method

A fuel tank and aircraft technology, applied in the field of aviation systems, can solve the problems of high inlet pressure of separation membrane, pollution of the environment, low efficiency of separation membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

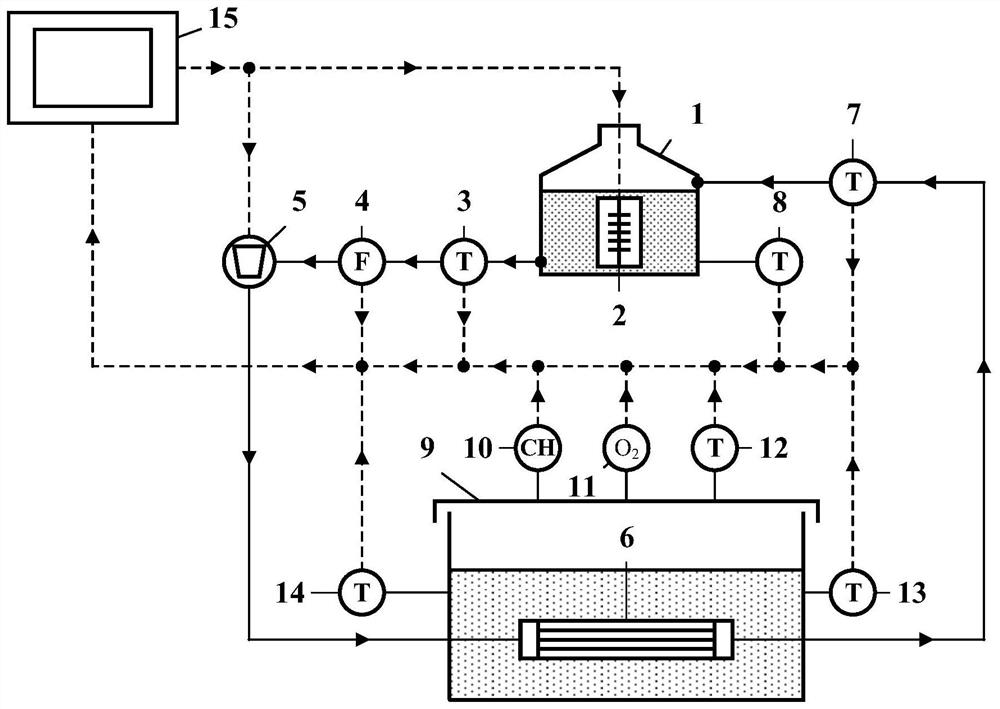

[0024] like figure 1 As shown, an aircraft fuel tank inerting system includes a heat exchanger 6 placed in the fuel tank 9, and the heat exchanger 6 is connected with a heating system. In this embodiment, the heating system includes a water pump 5 and a water tank 1 connected by pipelines. The outlet of the water tank 1 is connected to the water pump 5 by pipelines. A heater 2 is installed.

[0025] Both the heater 2 and the water pump 5 are connected to the controller 15, the pipeline between the water tank 1 and the water pump 5 is equipped with a first temperature sensor 3 and a first flow sensor 4, and the liquid phase space of the water tank 1 is connected with a third temperature sensor through a probe rod. Sensor 8, the pipeline between the heat exchanger 6 and the inlet of the water tank 1 is equipped with a second temperature sensor 7 .

[0026] The upper gas phase space of the fuel tank 9 is connected with a hydrocarbon concentration sensor 10, an oxygen concentrat...

Embodiment 2

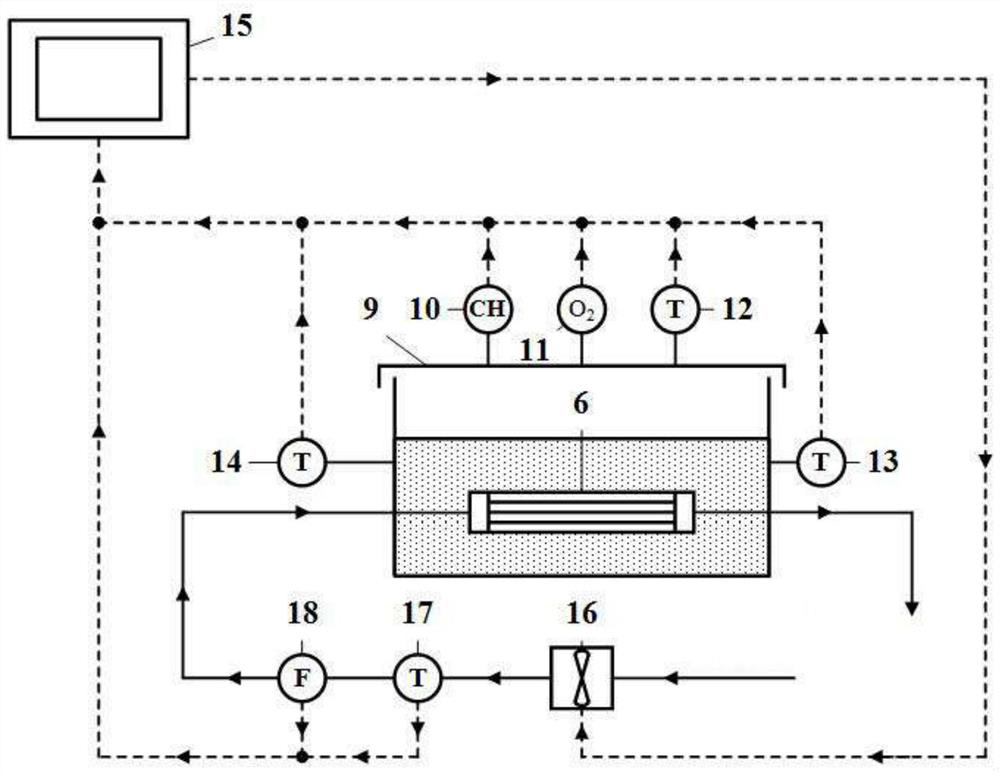

[0030] like figure 2 As shown, the structure of embodiment 2 is basically the same as that of embodiment 1. The difference is that the heating system in this embodiment includes an engine bleed air pipeline, and the engine bleed air pipeline is connected to a fan 16 through a pipeline, and the downstream of the fan 16 is connected to the heat exchanger 6 , The heat exchanger 6 outlet pipes are connected to the outside of the machine. The fan 16 is connected to the controller 15, the seventh temperature sensor 17, the second flow sensor 18 are installed on the pipeline between the fan 16 and the heat exchanger 6, the seventh temperature sensor 17, the second flow sensor 18, the hydrocarbon concentration The sensor 10, the oxygen concentration sensor 11, the fourth temperature sensor 12, the fifth temperature sensor 13, and the sixth temperature sensor 14 are connected in parallel with the controller 15 through cables.

[0031] When the aircraft fuel tank inerting system in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com