High-strength mass concrete and preparation method thereof

A mass concrete, high-strength technology, applied in the field of concrete, can solve the problems of uneven stress on the poured structure, reduced stability, local condensation, etc., to achieve the effect of promoting the mixing effect, improving the performance, and slowing down the hydration process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below, so that those skilled in the art can implement it with reference to the description.

[0023] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

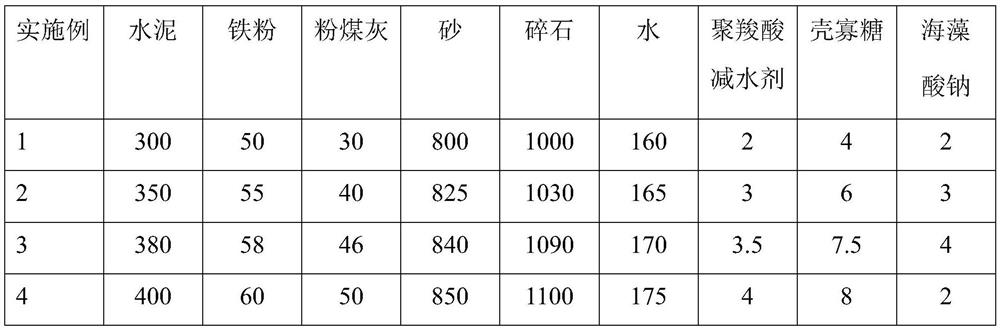

[0024] The invention provides a high-strength and large-volume concrete, which includes: 300-400 kg of cement, 50-60 kg of iron powder, 30-50 kg of fly ash, 800-850 kg of sand, 1000-1100 kg of gravel, and 160-60 kg of water per cubic meter of concrete. 175kg, polycarboxylate superplasticizer 2-4kg, chitosan oligosaccharide 4-8kg and sodium alginate 2-5kg.

[0025] In one of the embodiments of the present invention, as a preference, each cubic meter of concrete includes: 350kg of cement, 55kg of iron powder, 40kg of fly ash, 825kg of sand, 1030kg of gravel, 165kg of water, 3kg of polycarboxylate superplasticizer, Chitooligos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com