Preparation method of low-cost humidifying plastering gypsum

A low-cost technology for plaster plastering, which is applied in the field of plaster plastering and can solve problems such as the decline in anti-cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

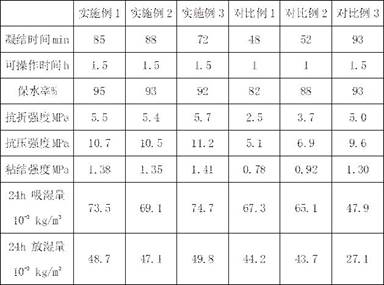

Examples

Embodiment 1

[0018] A method for preparing low-cost humidity-adjusting plaster plaster, comprising the following steps:

[0019] A. After the desulfurized gypsum is pre-dried at 82°C, it enters the fluidized calciner, calcined at 128°C, and then grinds it in an impact mill, and ages after cooling;

[0020] B. Stir the aged desulfurized gypsum and caustic white mud slag evenly, grind them repeatedly, and pass through a 325-mesh sieve;

[0021] C. Then add hydroxypropyl methylcellulose, lignocellulose, zinc oxide, Bonet and super high gel protein powder, stir evenly, grind and pass through a 200-mesh sieve.

[0022] The aging time in the described step A is 9 days.

[0023] In the step B, the causticizing white mud slag is causticizing white mud slag recovered from papermaking alkali with a water content of 12%.

[0024] In the step C, the raw material of the super high gelatinity protein powder is eggs. In the step C, the gel degree of the super high gel degree protein powder is 1300g*cm...

Embodiment 2

[0027] A method for preparing low-cost humidity-adjusting plaster plaster, comprising the following steps:

[0028] A. After the desulfurized gypsum is pre-dried at 90°C, it enters the fluidized calciner, calcined at 120°C, and then grinds it in an impact mill, and ages after cooling;

[0029] B. Stir the aged desulfurized gypsum and caustic white mud slag evenly, grind them repeatedly, and pass through a 325-mesh sieve;

[0030] C. Then add hydroxypropyl methylcellulose, lignocellulose, zinc oxide, Bonet and super high gel protein powder, stir evenly, grind and pass through a 200-mesh sieve.

[0031] The aging time in the described step A is 7 days.

[0032] In the step B, the causticizing white mud slag is causticizing white mud slag recovered from papermaking alkali with a water content of 15%.

[0033] In the step C, the raw material of the super high gelatinity protein powder is eggs. In the step C, the gel degree of the super high gel degree protein powder is 1200g*cm...

Embodiment 3

[0036] A method for preparing low-cost humidity-adjusting plaster plaster, comprising the following steps:

[0037] A. After the desulfurized gypsum is pre-dried at 80°C, it enters the fluidized calciner, calcined at 130°C, and then grinds in an impact mill, and ages after cooling;

[0038] B. Stir the aged desulfurized gypsum and caustic white mud slag evenly, grind them repeatedly, and pass through a 325-mesh sieve;

[0039] C. Then add hydroxypropyl methylcellulose, lignocellulose, zinc oxide, Bonet and super high gel protein powder, stir evenly, grind and pass through a 200-mesh sieve.

[0040] The aging time in the described step A is 10 days.

[0041] In the step B, the causticizing white mud slag is causticizing white mud slag recovered from papermaking alkali with a water content of 8%.

[0042] In the step C, the raw material of the super high gelatinity protein powder is eggs. In the step C, the gel degree of the super high gel degree protein powder is 1400g*cm -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com