Method for separating phenolic substances in medium-low temperature coal tar

A technology of low-temperature coal tar and phenolic substances, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as unfavorable environmental protection, complexity, and large amount of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

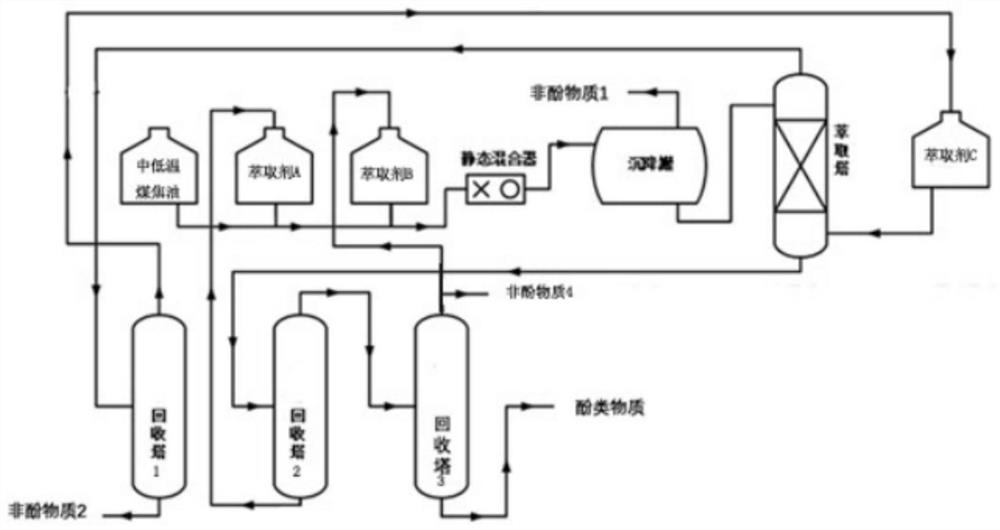

[0031] A method for separating phenolic substances in medium and low temperature coal tar. The medium and low temperature coal tar adopts two extraction and separation processes to separate phenolic substances with a purity greater than 99%. The specific steps are as follows:

[0032] (1) Medium and low temperature coal tar and mixed extractants A and B are uniformly mixed in a certain proportion, and after sedimentation and stratification, the upper layer is non-phenolic substance 1, and the lower layer is phenol-rich solvent;

[0033] (2) The separated phenol-rich solvent enters the extraction tower from the upper end of the tower, and the extractant C enters the extraction tower from the lower end of the tower, and undergoes countercurrent extraction;

[0034] (3) The top component of the extraction tower enters the recovery tower 1, and the top component of the recovery tower 1 is an extractant C, which is recycled, and the bottom component of the tower is a non-phenolic su...

Embodiment 2

[0042] A method for phenolic substances in medium and low temperature coal tar. The medium and low temperature coal tar adopts two extraction and separation processes to separate phenolic substances with a purity greater than 99%. The specific steps are as follows:

[0043] (1) Medium and low temperature coal tar and mixed extractants A and B are uniformly mixed in a certain proportion, and after sedimentation and stratification, the upper layer is non-phenolic substance 1, and the lower layer is phenol-rich solvent;

[0044] (2) The separated phenol-rich solvent enters the extraction tower from the upper end of the tower, and the extractant C enters the extraction tower from the lower end of the tower, and undergoes countercurrent extraction;

[0045] (3) The top component of the extraction tower enters the recovery tower 1, and the top of the recovery tower 1 is the extractant C, which is recycled, and the bottom of the tower is the non-phenolic substance 2;

[0046] (4) The...

Embodiment 3

[0053] A method for separating phenolic substances in medium and low temperature coal tar. The medium and low temperature coal tar adopts two extraction and separation processes to separate phenolic substances with a purity greater than 99%. The specific steps are as follows:

[0054] (1) Medium and low temperature coal tar and mixed extractants A and B are uniformly mixed in a certain proportion, and after sedimentation and stratification, the upper layer is non-phenolic substance 1, and the lower layer is phenol-rich solvent;

[0055] (2) The separated phenol-rich solvent enters the extraction tower from the upper end of the tower, and the extractant C enters the extraction tower from the lower end of the tower, and undergoes countercurrent extraction;

[0056] (3) The top component of the extraction tower enters the recovery tower 1, and the top of the recovery tower 1 is the extractant C, which is recycled, and the bottom of the tower is the non-phenolic substance 2;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com