Catalyst for reaction of isocyanate and sulfydryl and preparation method of catalyst

A technology of isocyanate and catalyst, which is applied in the field of catalyst and its preparation for catalyzing the reaction between isocyanate and mercapto group, and can solve problems such as high activity, affecting product viscosity and structural regularity, and inability to prepare clean odor products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method for the catalyst of isocyanate and mercapto reaction, the steps are as follows:

[0025] S1-1: Add 480g of 3-mercaptopropyltriethoxysilane and 351.03g of dibutyltin diacetate into the reactor, stir evenly, heat to 90°C, and maintain the reaction for 4 hours;

[0026] S1-2: Keep the reaction temperature at 90°C and then connect the condenser tube to vacuumize the system so that the vacuum degree is kept below -0.1MPa, and remove the acetic acid generated by the reaction until there is no low boiling material dripping from the condenser tube;

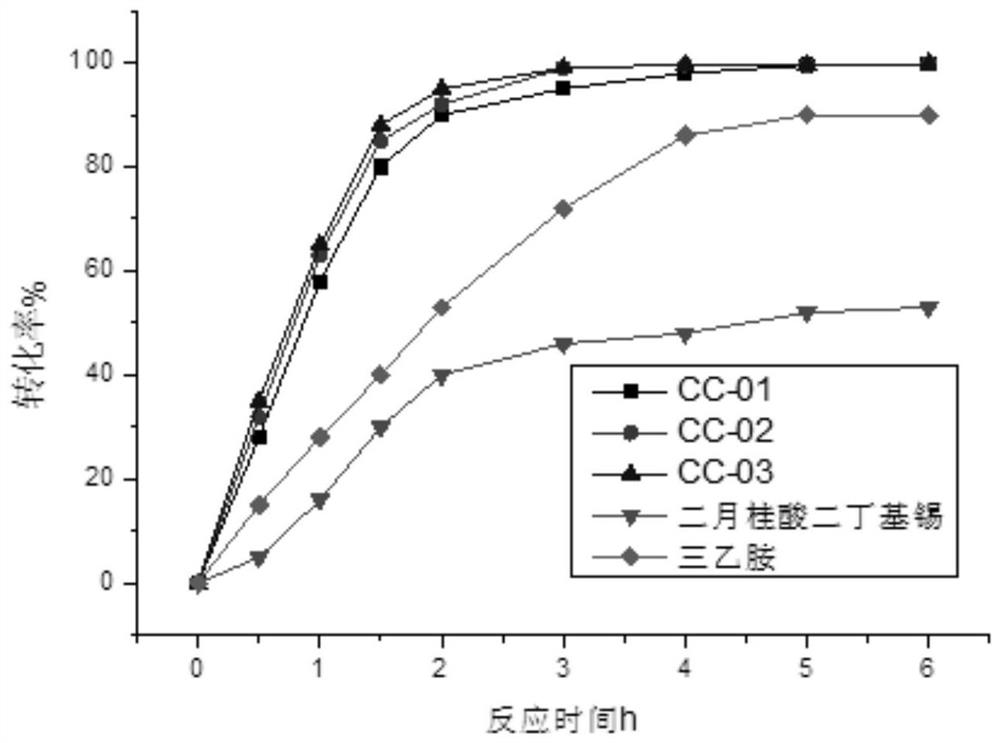

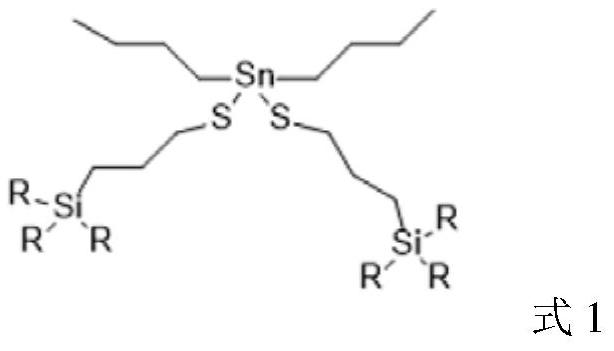

[0027] S1-3: Keep the reaction temperature at 120°C and continue vacuuming for 2 hours, remove the excess mercaptosiloxane, stop the reaction and discharge the product, and the product obtained is a catalyst for the reaction between isocyanate and mercapto group (marked as catalyst CC- 01, the structure is shown in Formula 1, where R is -OCH 2 CH 3 ), the state is a light yellow transparent liquid, wi...

Embodiment 2

[0029] A kind of preparation method for the catalyst of reaction of isocyanate and mercapto group, the steps are as follows:

[0030] S1-1: Add 400g of 3-mercaptopropyltrimethoxysilane and 351.03g of dibutyltin diacetate into the reactor, stir evenly, heat to 85°C, and maintain the reaction for 5 hours;

[0031] S1-2: Keep the reaction temperature at 85°C and then connect the condenser tube to vacuumize the system so that the vacuum degree is kept below -0.1MPa, and remove the acetic acid generated by the reaction until there is no low boiling material dripping from the condenser tube;

[0032] S1-3: Keep the reaction temperature at 110°C and continue vacuuming for 2.5 hours, remove the excess mercaptosiloxane, stop the reaction and discharge the product, and the product obtained is a catalyst for the reaction between isocyanate and mercapto group (marked as catalyst CC- 02, the structure is shown in Formula 1, where R is -OCH 3 ), the state is a light yellow transparent liqu...

Embodiment 3

[0034] A kind of preparation method for the catalyst of reaction of isocyanate and mercapto group, the steps are as follows:

[0035] S1-1: Add 240g of 3-mercaptopropyltriethoxysilane, 200g of 3-mercaptopropyltrimethoxysilane and 351.03g of dibutyltin diacetate into the reactor, stir evenly, heat to 88°C, and maintain React for 4 hours;

[0036] S1-2: Keep the reaction temperature at 88°C and then connect the condenser tube to vacuumize the system so that the vacuum degree is kept below -0.1MPa, and remove the acetic acid generated by the reaction until there is no low boiling material dripping from the condenser tube;

[0037] S1-3: Keep the reaction temperature at 115°C and continue vacuuming for 2.5 hours, remove the excess mercaptosiloxane, stop the reaction and discharge the product, and the product obtained is a catalyst for the reaction between isocyanate and mercapto group (marked as catalyst CC- 03, the structure is shown in Formula 1, and R is -OCH respectively 2 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com