A kind of phosphorescent polymer material and its preparation method and application

A polymer material, epoxy polymer technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of oxygen consumption, vibration dissipation, etc., and achieve cheap raw materials, good stability, and high phosphorescence quantum yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing a high-efficiency and long-life room temperature phosphorescent polymer material, including Scheme 1 and Scheme 2:

[0047] The organic phosphorescent small molecules shown in formula A and formula B are suitable for scheme one:

[0048] Dissolve the organic phosphorescent small molecules shown in formula A and formula B in the above epoxy matrix under the protection of nitrogen, stir evenly, and cool to room temperature; mix this mixture with the above liquid curing agent in a certain proportion, and stir until transparent , injected into the mold, after curing, the phosphorescent material is obtained.

[0049] The organic phosphorescent small molecules represented by formula C, formula D, and formula E are suitable for scheme two:

[0050] Dissolve the small organic phosphorescent molecules shown in Formula C, Formula D, and Formula E in the above-mentioned liquid curing agent in a certain proportion, and stir evenly; mix the mixture with the a...

Embodiment 1

[0054] Preparation of a pure organic high-efficiency long-life room temperature phosphorescent polymer material doped with molecules represented by formula A (N,N,N',N'-tetramethylbenzidine), the preparation steps are as follows:

[0055] The organic phosphorescent small molecule (TMB molecule) represented by formula A was dissolved in the epoxy matrix 2,2-bis-(4-glycylaminophenyl)propane under the protection of nitrogen, stirred evenly and then cooled to room temperature. The molar ratio of the organic phosphorescent small molecule to the epoxy group in the epoxy matrix is 1:100. Mix this mixture with the aliphatic curing agent ethylenediamine, where the molar ratio of curing agent ethylenediamine to epoxy groups in the epoxy matrix is 1:2. After stirring until transparent, pour into the mold, first keep at 25°C for 24 hours, and then keep at 80°C for 4 hours to obtain the phosphorescent material.

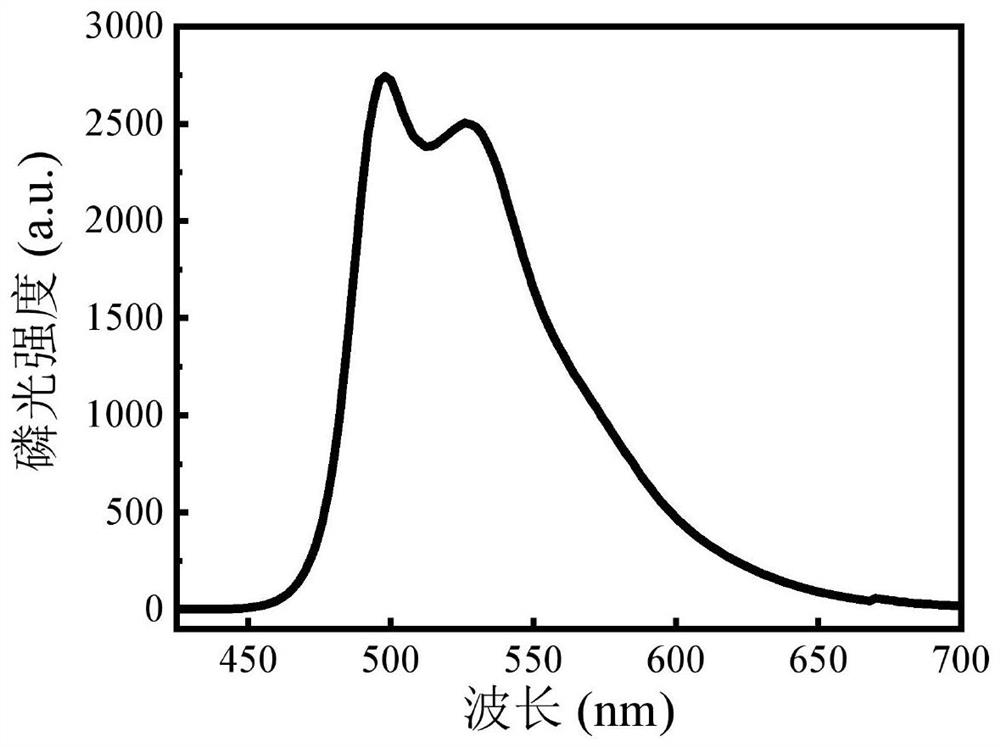

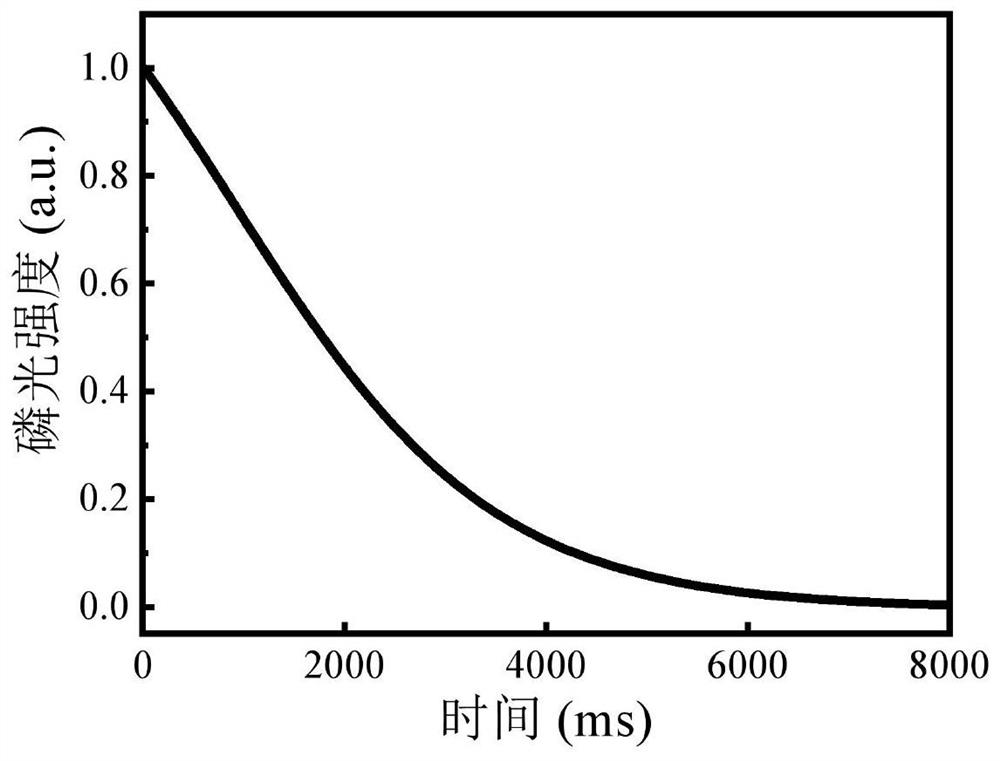

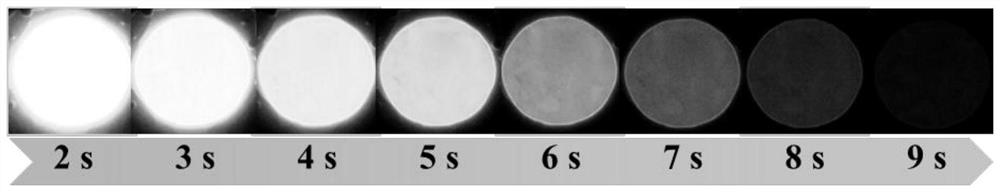

[0056] figure 1 It is the phosphorescence spectrum of the pure organic ...

Embodiment 2

[0058] To prepare a pure organic high-efficiency long-life room temperature phosphorescent polymer material doped with molecules (triphenylamine) shown in formula B, the preparation steps are as follows:

[0059] The organic phosphorescent small molecule (triphenylamine) represented by formula B was dissolved in the epoxy matrix 2,2-bis-(4-glycylaminophenyl)propane under the protection of nitrogen, stirred evenly and then cooled to room temperature. The molar ratio of the organic phosphorescent small molecule to the epoxy group in the epoxy matrix is 1:100. Mix this mixture with the aliphatic curing agent ethylenediamine, where the molar ratio of curing agent ethylenediamine to epoxy groups in the epoxy matrix is 1:2. After stirring until transparent, pour into the mold, first keep at 25°C for 24 hours, and then keep at 80°C for 4 hours to obtain the phosphorescent material.

[0060] Figure 5 is the phosphorescence spectrum of the prepared pure organic high-efficiency l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com