Continuous glass fiber reinforced polypropylene prepreg tape and preparation method thereof

A technology of glass fiber and prepreg tape, applied in the field of composite material board, can solve the problems of poor bonding between resin and glass fiber and high porosity, and achieve the effect of good strength and surface finish, excellent performance and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A continuous glass fiber reinforced polypropylene prepreg tape and a preparation method thereof, the technological process is as follows:

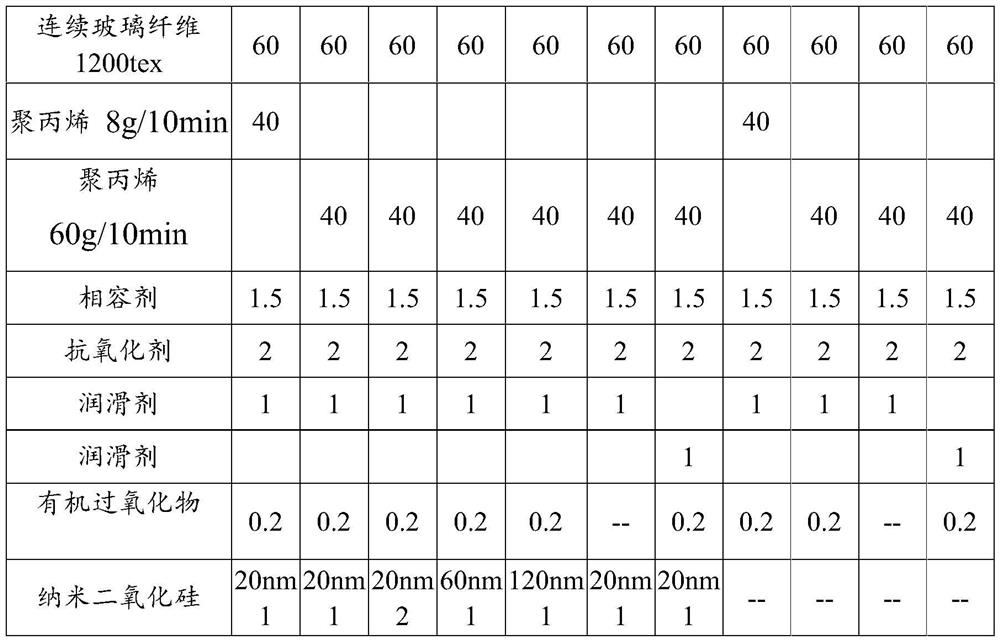

[0030] Step 1, weighing the raw materials according to the weight ratio, each component and its ratio data are shown in Table 1;

[0031] Step 2: Mix and stir the raw materials except the continuous glass fiber and put them into the screw extruder. The temperature of the extruder has five sections in total. The first section is set at 180°C, and the second section is set at 220°C. The third, fourth and fifth stages are set at 240°C. The high-temperature melt is transported to the prepreg die through the screw extruder, and then enters the impregnation mold through the die. ℃.

[0032] Step 3, drawing the continuous glass fiber through the high-temperature impregnation mold at a speed of 3-15m / min, and after being fully impregnated, drawing it through the rolling equipment, cooling and molding to obtain the continuous glass fiber re...

Embodiment 2~7

[0034] The raw materials of each component were weighed according to the weight distribution data provided in Table 1, and the rest of the implementation process was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com