Integrated double-tower ethane recovery device and recovery process

A recovery device and double-column ethane technology are applied in the field of integrated double-column ethane recovery device and recovery process, which can solve the problems of large number of equipment and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

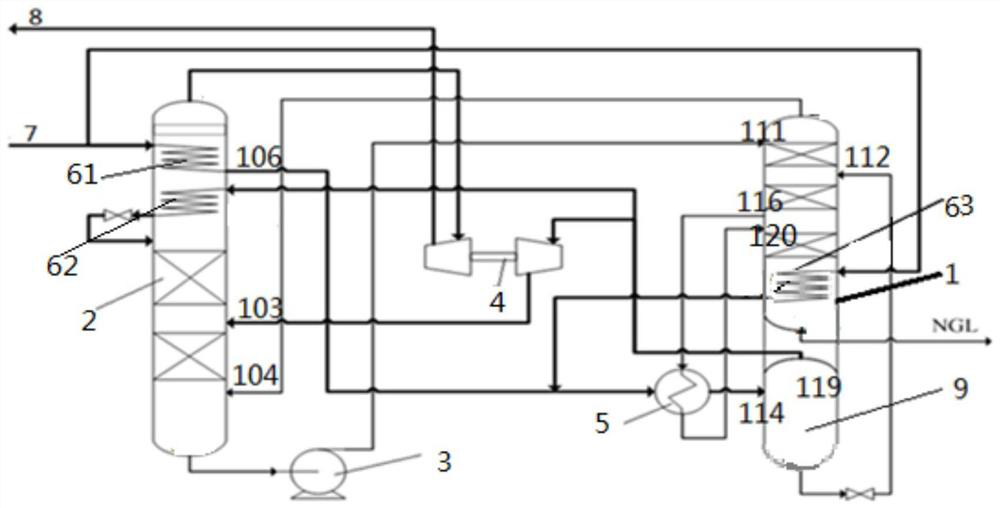

[0026] Such as figure 1 As shown, the present invention is an integrated double-tower ethane recovery device, which includes a stripping integrated tower 1 and a rectifying integrated tower 2. The stripping integrated tower 1 is provided with a first integrated raw material gas precooling heat exchange winding. Pipe 63, the upper end of the rectification integrated tower 2 is provided with a second integrated raw material gas precooling heat exchange coil 61, and the lower part of the second integrated raw material gas precooling heat exchange coil 61 is provided with an integrated supercooled air exchange coil The heat coil 62, the raw material gas is divided into two branches, namely the first branch and the second branch, and the first branch is arranged in sequence along the airflow output direction as the second integrated raw material gas precooling heat exchange coil 61, Raw material gas precooler 5 and separator 9, the second branch along the airflow output direction i...

Embodiment 2

[0028] Such as figure 1 As shown, the present embodiment is based on embodiment 1, the outlet of the lower part of the rectification integration tower 2 is connected to the third packing area inlet 111 through a pipeline, and the third packing area inlet 111 is located at the top of the stripping integration tower 1, so The rectification integration tower bottom pump 3 is arranged on the pipeline; the separator outlet 119 is arranged on the top of the separator 9, and the precooled feed gas at the outlet of the separator is divided into two branches, and the first branch and The expansion end of the expander 4 is connected, the outlet of the expansion end of the expander 4 is connected to the inlet 103 of the first packing area of the rectification integrated tower 2, and the second branch is connected to the inlet of the integrated supercooled gas heat exchange coil 62; The outlet at the top of the rectification integrated tower 2 is connected to the pressurized end of the ...

Embodiment 3

[0030] Such as figure 1 As shown, the present embodiment is based on embodiments 1 and 2 to realize a recovery process of an integrated double-tower ethane recovery device, comprising the following steps:

[0031] S1: After the raw material gas at the outlet end 7 of the raw material gas pipe enters the device, it is divided into two parts, and a part of the raw material gas enters the second integrated raw material gas precooling coil inlet 101 through the first integrated raw material gas precooling and heat exchange coil inlet 101 at the top of the rectification integrated tower 2. The cold heat exchange coil 61 is then passed through the outlet 106 of the first integrated raw material gas precooling heat exchange coil to enter the raw material gas precooler 5 for precooling, and the other part passes through the second integrated raw material gas precooling exchange in the middle of the stripping integrated tower 1 The heat coil inlet 113 enters the first integrated raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com