Multistage biological fermentation system

A biological fermentation and two-stage fermentation technology, applied in the field of multi-stage biological fermentation system, can solve the problems of single function, restriction of large-scale production, and long time consumption, so as to achieve uniform fermentation and ensure the effect of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

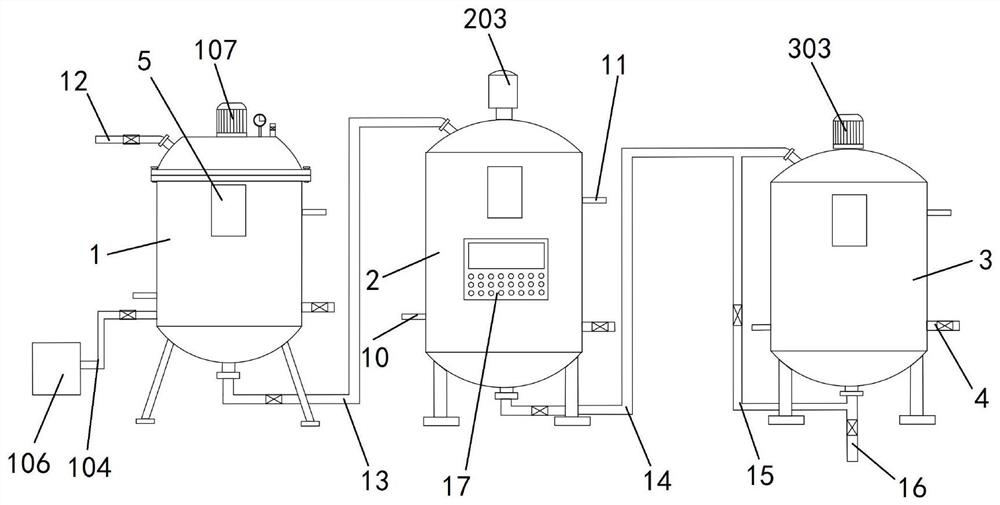

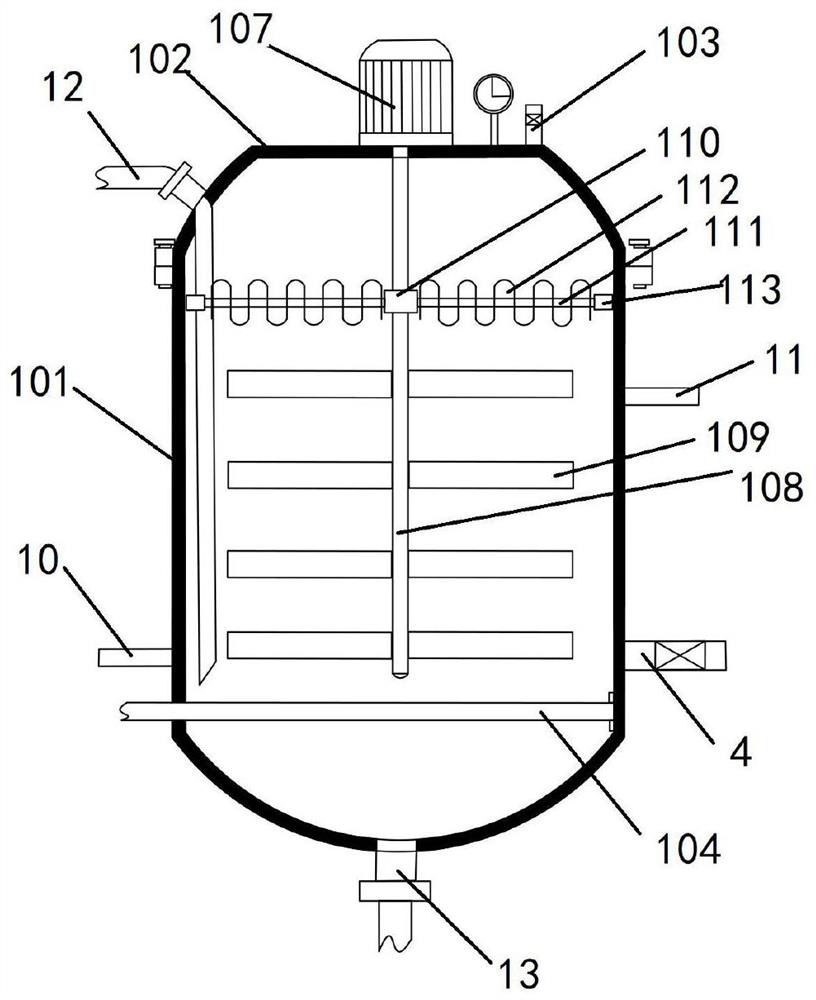

[0025] Embodiments of the present invention provide a multi-stage biological fermentation system, such as figure 1 As shown, it includes a primary fermentation tank 1, a secondary fermentation tank 2, a tertiary fermentation tank 3, a primary feed pipeline 12, a secondary feed pipeline 13, a tertiary feed pipeline 14, and a return pipeline 15. The discharge pipeline 16 and the electric control box 17, one end of the primary feed pipeline 12 extends from the feed inlet on the top of the primary fermentation tank 1 to the inner bottom of the primary fermentation tank 1, and the secondary feed pipeline 13 One end communicates with the discharge port at the bottom of the primary fermenter 1, the other end of the secondary feed pipeline 13 runs through the feed port at the top of the secondary fermenter 2 and extends to the inner bottom of the secondary fermenter 2, and the third stage One end of the feed pipeline 14 communicates with the discharge port at the bottom of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com