Porogen particle, preform, metal foam and preparation method thereof

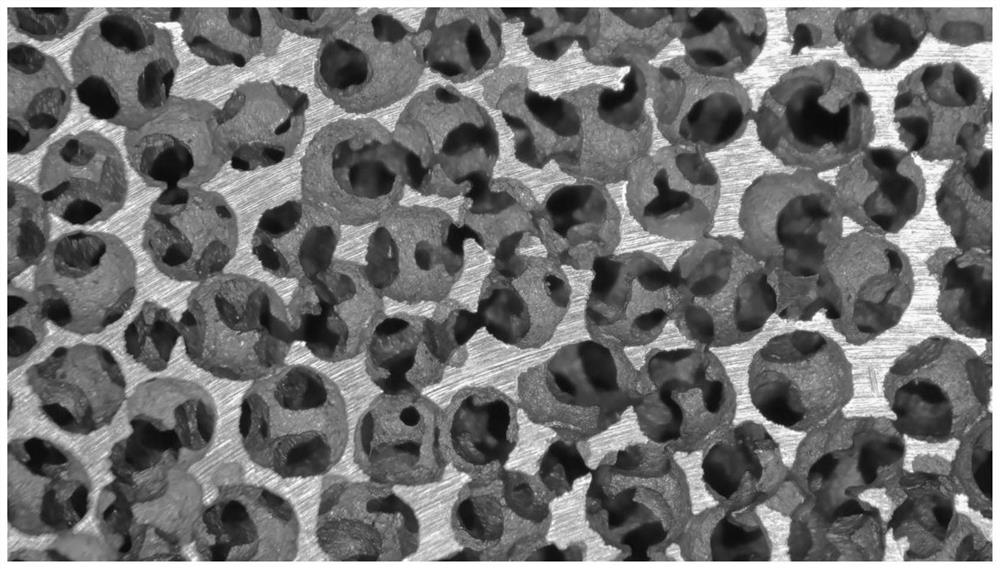

A technology of foam metal and pore-forming agent, applied in the field of foam metal, can solve the problems of difficult removal of pore-forming particles, low porosity of open-cell aluminum foam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

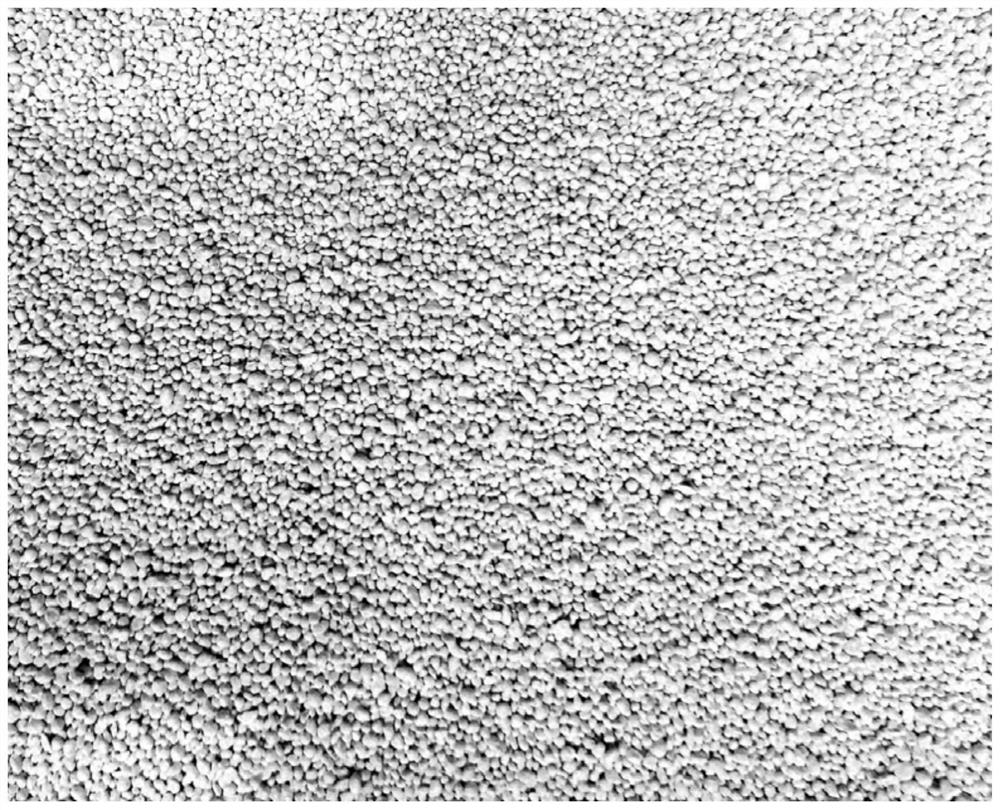

[0041] The embodiment of the present invention also provides a preparation method of the pore-forming agent particles, comprising the following steps:

[0042] mixing the water-soluble inorganic salt, kaolin and bentonite to obtain a mixture;

[0043] Put the mixture into the granulation container of the agglomeration granulation equipment, spray water to granulate, wherein, the rotation speed of the agglomeration granulation equipment is 20r / min~50r / min, and the inclination angle of the granulation container is 40° ~50°;

[0044] After the mixture in the agglomeration granulation equipment forms granules, increase the speed of the agglomeration granulation equipment by 5r / min to 20r / min, and increase the inclination angle of the granulation container by 1° to 5° , last for 3min~5min;

[0045] The granules in the agglomeration granulation equipment are taken out for drying.

[0046] In some embodiments, the mixing of the water soluble inorganic salt, kaolin and bentonite ma...

Embodiment 1

[0066] The components are NaCl microparticles, kaolin and bentonite and are uniformly mixed with a mixer to obtain a mixture. Add the mixed material into the disc of the disc granulator, spray water to granulate, wherein, the rotating speed of the granulator is 20r / min, and the inclination angle of the granulation container is 40°. After the mixture in the disc granulator forms granules, increase the rotational speed of the granulator by 10r / min, and increase the inclination angle of the granulator by 2° for 5 minutes. The granules in the granulator are taken out for drying. The mass percentages of NaCl particles, kaolin and bentonite in the solids in the pore-forming particles were 20%, 75% and 5% respectively, and the mass ratio of water and solids in the process of preparing the pore-forming agent particles was 1:7. The moisture content in the obtained pore former particles was about 9%.

[0067] Use a sieve to sieve the granules within a range of 2 mm for later use, and ...

Embodiment 2

[0073] Divide components into CaCl 2 The powder, kaolin and bentonite are uniformly mixed with a mixer to obtain a mixture. Put the mixture into the disc of the disc granulator, spray water to granulate, wherein, the rotational speed of the granulator is 20r / min-50r / min, and the inclination angle of the granulation container is 40°-50°. After the mixture in the disc granulator forms granules, increase the rotational speed of the granulator by 5r / min to 20r / min, and increase the inclination angle of the granulator by 3° for 3min to 5min. The granules in the granulator are taken out for drying. CaCl in pore-forming particles 2 The mass percentages of powder, kaolin and bentonite in solid are 40%, 55% and 5% respectively. The mass ratio of water and solids during the preparation of pore-forming agent particles is 1:10. The moisture content in the obtained pore former particles was about 7%.

[0074] Use a sieve to screen the granules within a range of 3 mm for use, and stack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com