Fabric printing and dyeing process device

A printing and dyeing process and fabric technology, applied in the field of fabric processing, can solve the problems of inability to recycle printing and dyeing water, affect the working environment of the workshop, and splashing of printing and dyeing water, and achieve the effect of active and rapid dyeing water, reducing dyeing water, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

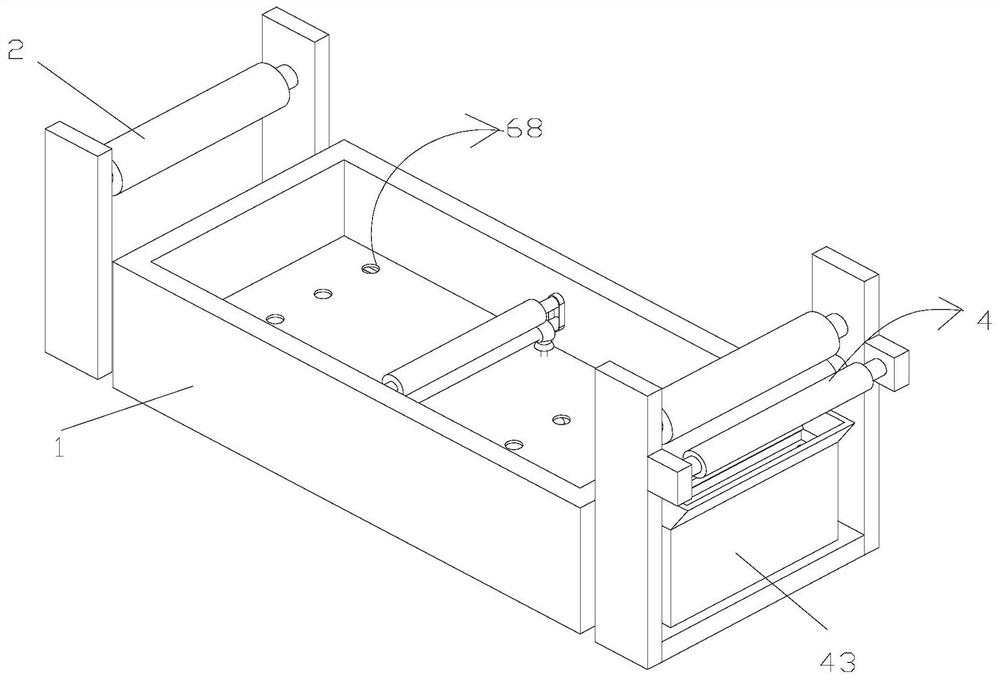

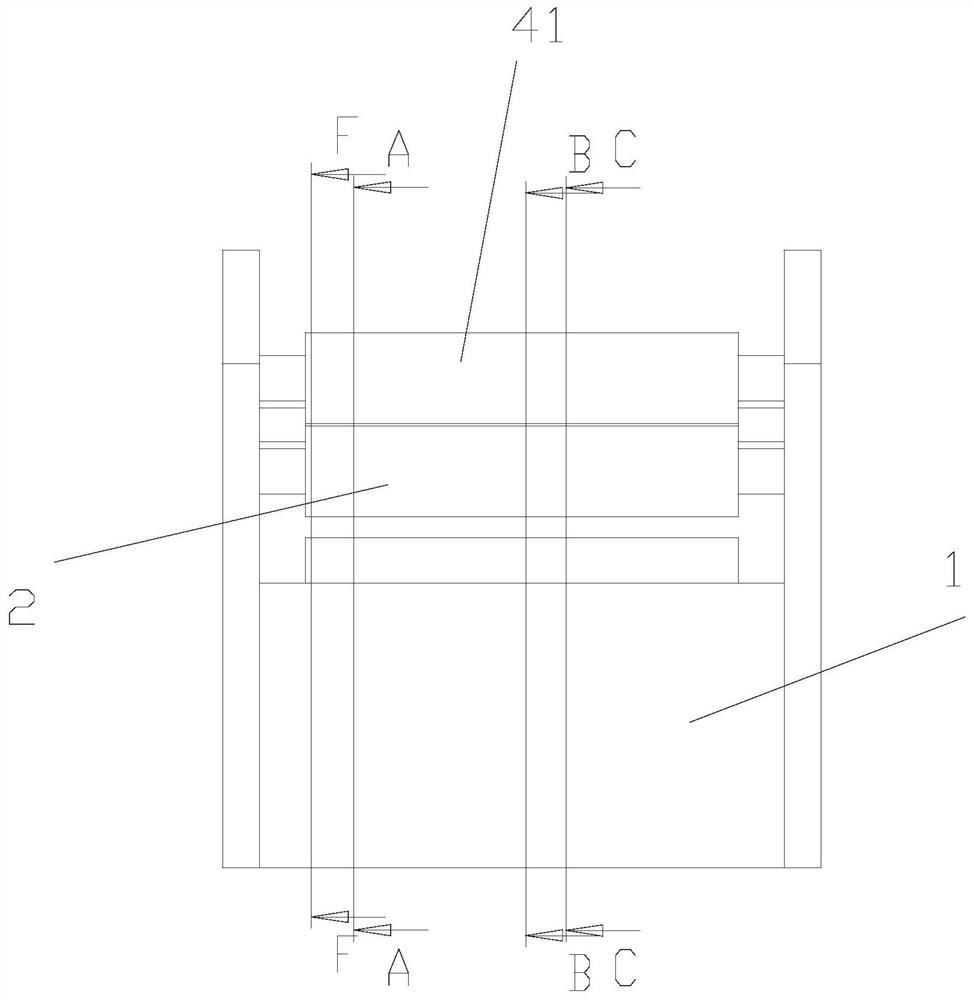

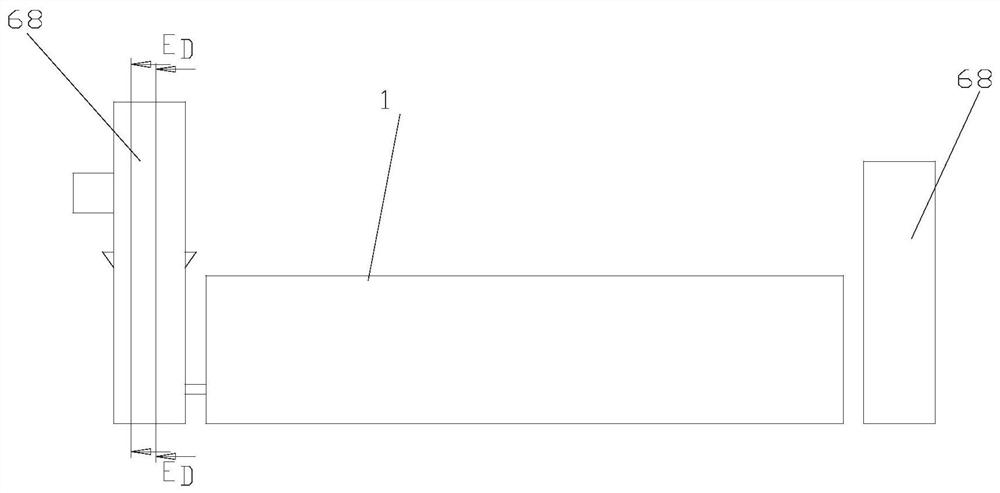

[0042] Such as Figure 1-20 As shown, a fabric printing and dyeing process device includes a printing and dyeing pool 1, a discharging roller 2, a receiving roller 3, an extrusion device 4 and a printing and dyeing device 5; the discharging roller 2 is located on the left side of the printing and dyeing pool 1; The receiving roller 3 is arranged on the right side of the printing and dyeing pool 1; the extruding device 4 is arranged on the receiving roller 3;

[0043] Described extruding device 4 comprises support plate 401, the first pressing roller 40, the second pressing roller 41, the 3rd pressing roller 42, dyeing collection box 43, outlet pipe 44, beating device 6 and collecting device 7; The number of 40 is two, which are respectively arranged on the front and rear sides of the printing and dyeing pool 1; the first pressing roller 40 is embedded in the middle of a pair of support plates 401 to rotate; the second pressing roller 41 is arranged on the lower part of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com