Frame type roadbed retaining structure

A technology of supporting structure and frame structure, which is applied in basic structure engineering, underwater structure, building structure, etc., can solve the difficulty of forming anchor cable holes, high construction safety risks, and the lack of research and specification of ordinary roadbed retaining walls. Perfect and other problems, to achieve reliable anti-falling rock performance, reduce construction difficulty and risk, and achieve the effect of adding value to the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

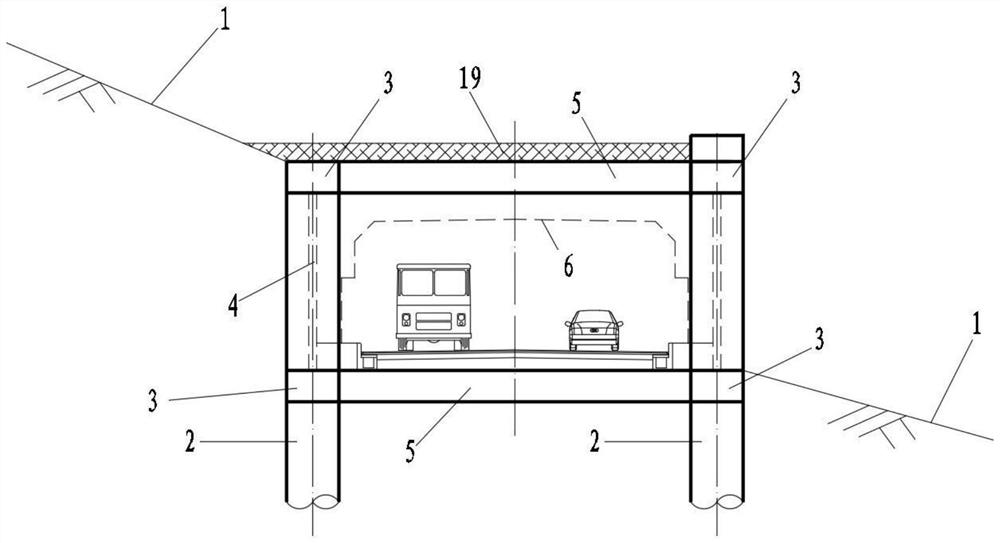

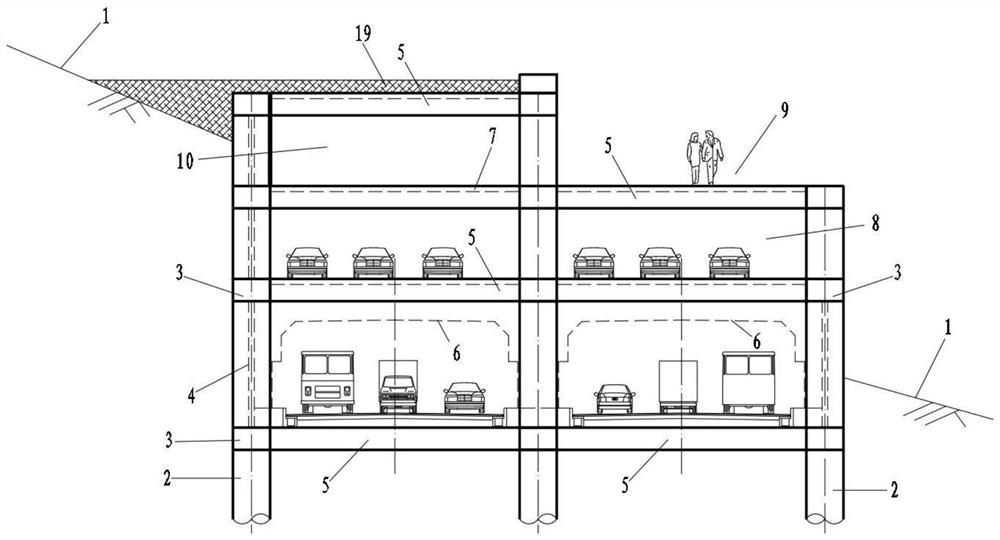

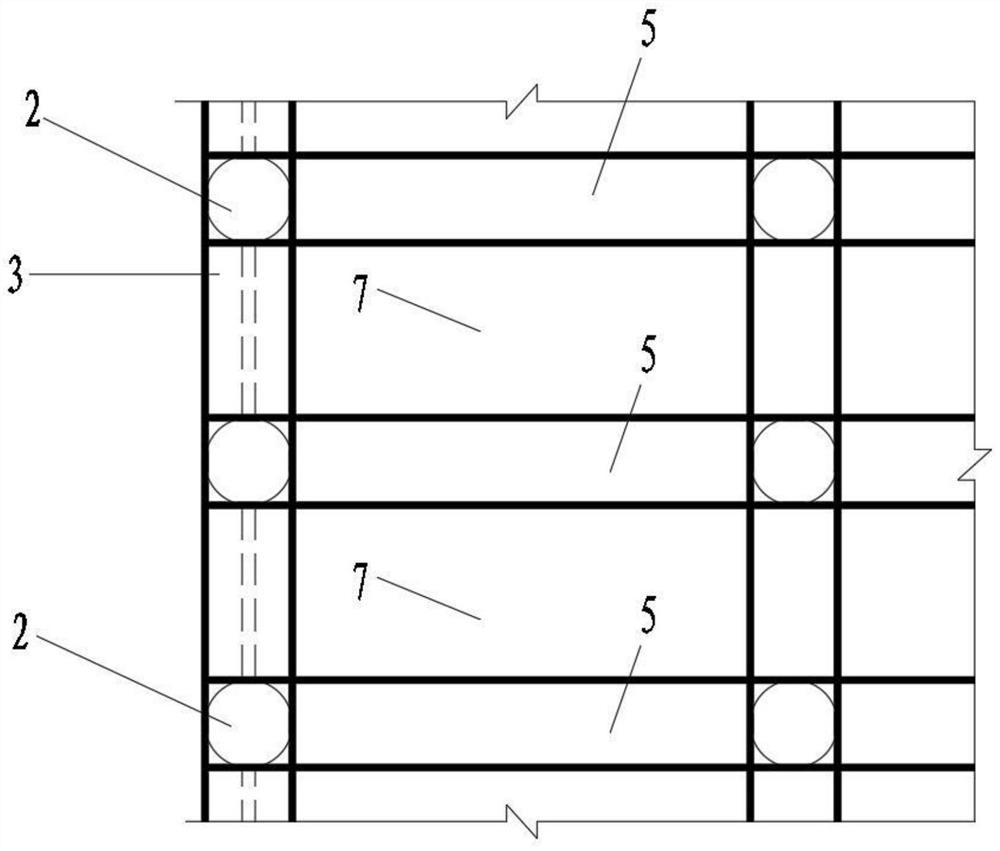

[0053] The utility model relates to a frame-type subgrade support structure, which is a multi-layered frame structure. Such as Figure 6 Shown: The road building boundary 6 is located in the middle of the mountain slope 1. The residual fill soil on the slope surface is formed by urban construction, and the thickness of the fill soil is 20-30m. The current situation is the green area of the mountain park, with the underlying bedrock. After the road cutting is excavated, the upper slope of the road will slide, and the sliding force of the landslide is converted to the anti-slide piles, which are distributed according to a rectangle, and the load of the landslide body 16 that each pile bears is 400KN / m. According to the layout of the road width, four rows of anti-slide piles with circular cross-section are used to support the block. The anti-slide piles 2 need to be embedded below the soil-rock boundary line 11, and the anti-slide piles 2 are preferably embedded 9m to 10m below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com