Mechanical vacuum pump

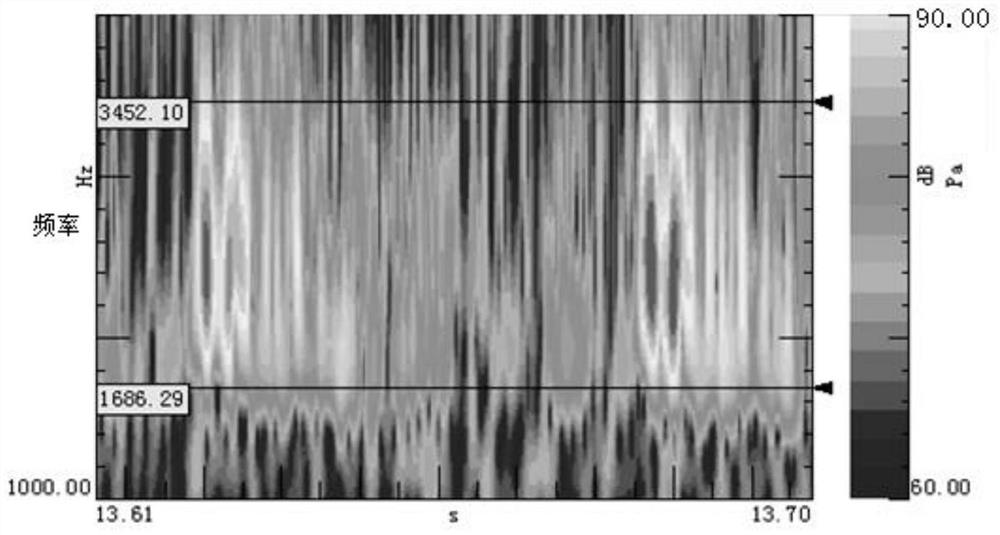

A mechanical vacuum pump and pump body technology, applied in mechanical equipment, pumps, pump components, etc., can solve problems such as not meeting requirements, and achieve the effects of improving sound quality, reducing strength, and reducing percussion noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following combined with the attachment is further explained to the present invention.

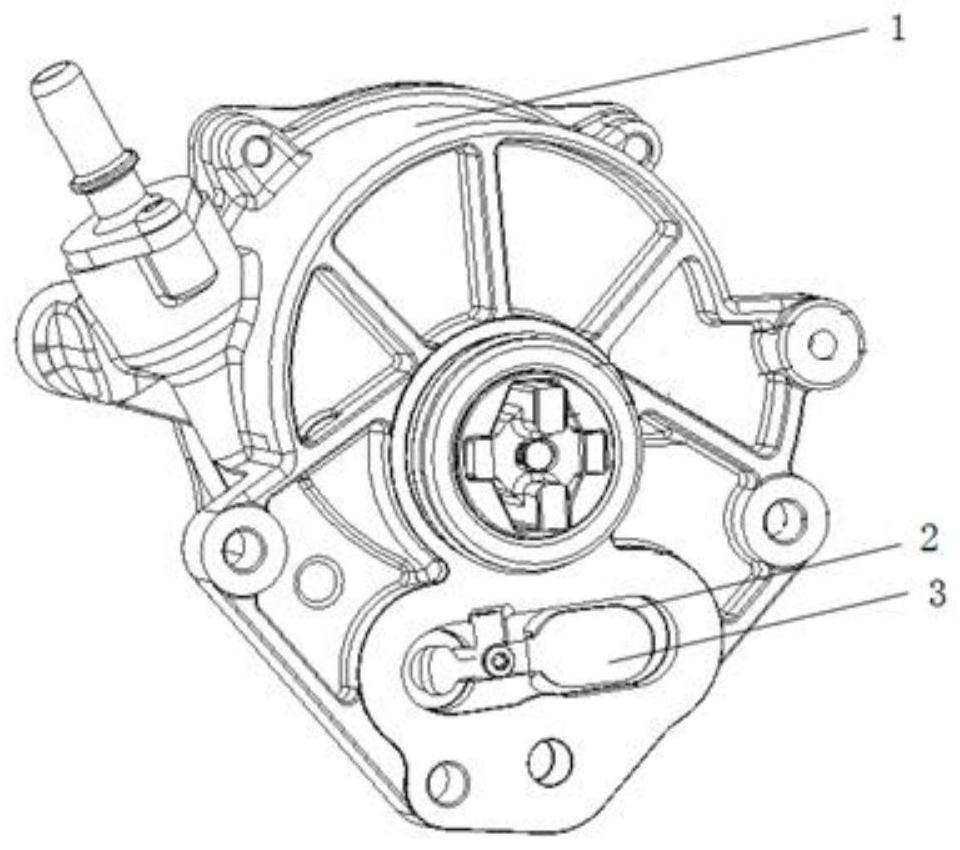

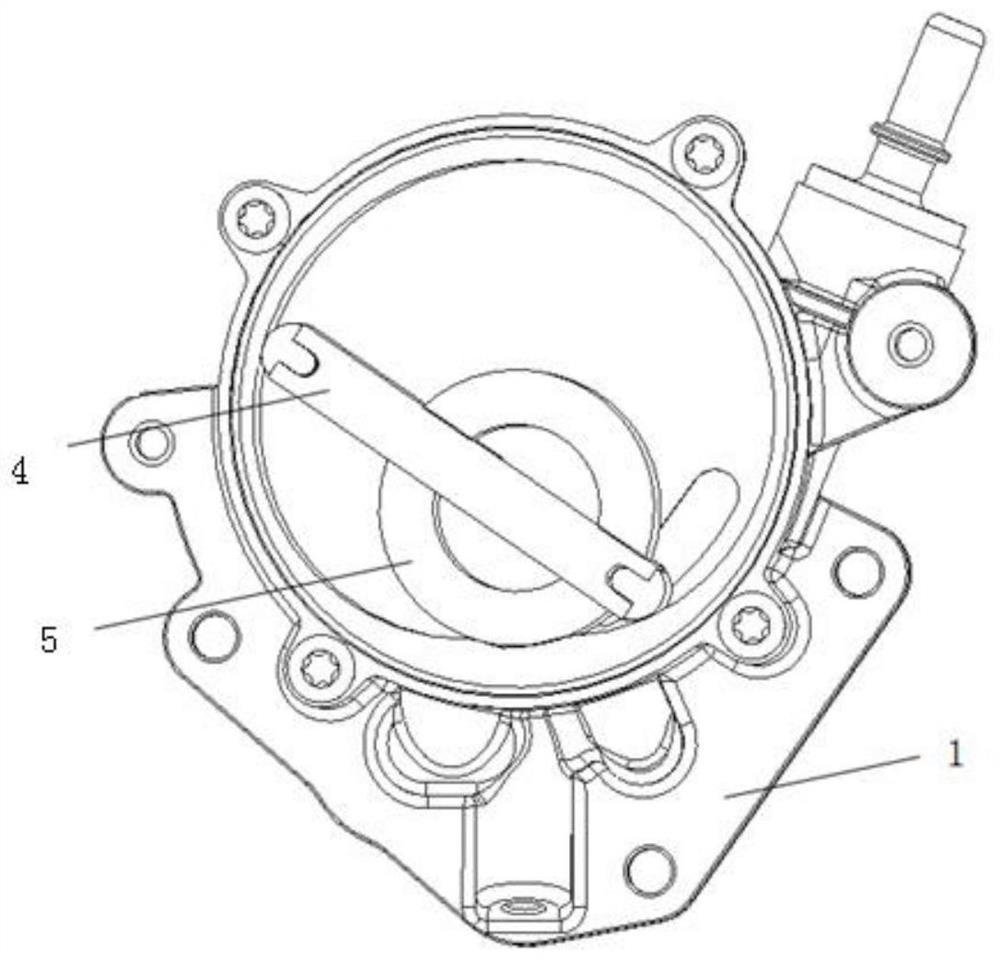

[0020] like Figure 5 and Image 6 In, in this embodiment, a mechanical vacuum pump, including pump body 1, exhaust valve tablet 2, and balcony 3. The pump body 1 has an exhaust cavity 7. Valve seat 8, the exhaust valve sheet 2 and the baffle 3 are installed on the exhaust valve seat 8 through a fixed screw 6, and also includes the pressure cavity 9 set on the back of the exhaust valve tablet 2 There is an exhaust hole 10; when the vacuum pump is exhausted, the gas enters the pressure cavity 9, and then enter the cylinder cap through the exhaust holes on the pressure cavity 9. During the exhaust process, the pressure in the pressure cavity 9 can continue to be greater than the pressure in the cylinder cap, so that the pressure on the back of the exhaust valve tablet 2 will not be reduced rapidly, so that the front and back pressure difference between the exhaust valve tablet 2 is less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com