Motor bearing fault diagnosis method and device based on signal enhancement and compression edge calculation

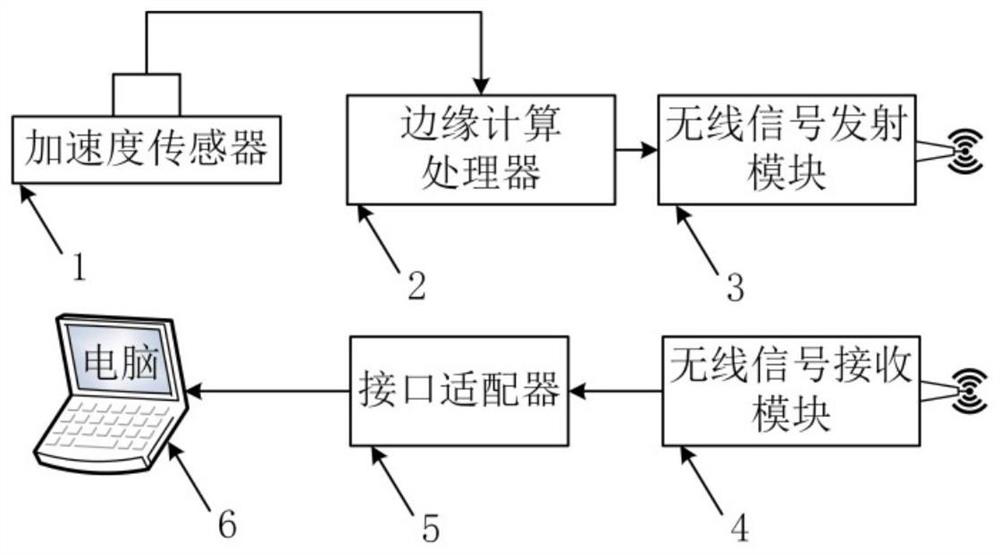

A technology for fault diagnosis device and motor bearing, which is applied to services, measurement devices, signal transmission systems based on specific environments, etc., and can solve problems such as busy transmission channels, sudden increase in computing and storage pressure in data centers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

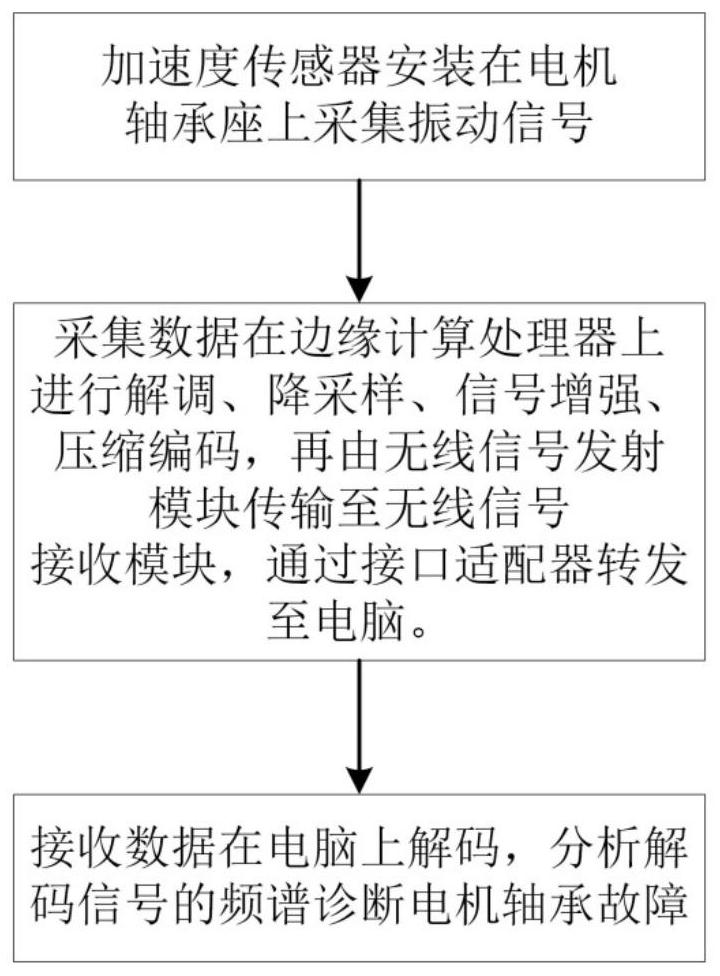

Method used

Image

Examples

Embodiment 1

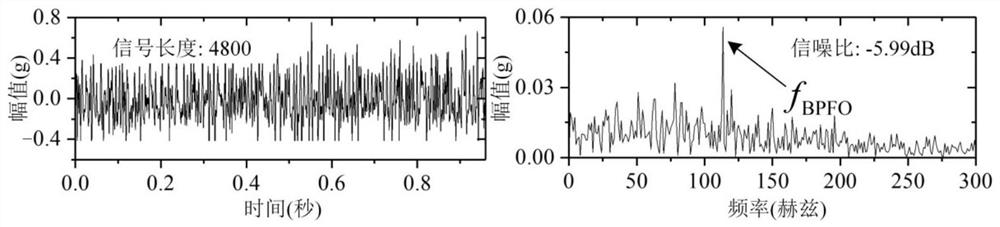

[0074] This embodiment illustrates the practicability and superiority of the present invention by analyzing the fault signal of the outer ring of the motor bearing. The model of the motor bearing is 6002Z, and the motor speed is 1283RPM. From this, the characteristic frequency f of the outer ring fault of the bearing can be calculated BPFO is 115.6Hz. use figure 1 As shown in the IoT node device proposed by the present invention, according to step 1 of the method of the present invention, the acceleration sensor in the device of the present invention is installed on the motor bearing seat. Set the sampling frequency to 5kHz, the sampling time to 0.96 seconds, and the number of collected data points to 4800.

[0075] According to step 2 of the method of the present invention, the signal is demodulated, down-sampled and signal enhanced on the edge computing processor. The square low-pass filter algorithm of the present invention is used to demodulate the signal, and the demod...

Embodiment 2

[0078] In order to further reflect the superiority of the method of the present invention, the transmission time, power consumption and other performances of the method of the present invention and the traditional method are compared through experiments. The method of the invention includes four stages of signal collection, signal preprocessing, signal compression and signal transmission, wherein the signal preprocessing includes demodulation, down-sampling and signal enhancement processes. The traditional method only includes two stages of signal acquisition and signal transmission, that is, the collected data is directly sent to the computer terminal for processing without processing. The comparison results of the two methods are as follows Figure 7 as shown, Figure 7 The above is the power consumption diagram of the method of the present invention. It can be seen from the diagram that the power consumption curve changes dynamically with the execution of the algorithm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com